AUTOMOTIVE ANWENDUNGEN

Dünnschicht-Präzisionswiderstand 0,01%, TC2ppm, Drahtbondable, Anti-Korrosiv, MELF. Strommessung, Metall,...

WeiterlesenMehrschicht-Ferrit-Chip-Induktor, kleine Größen, geschlossener magnetischer Kreis vermeidet Übersprechen, geeignet für die Installation mit hoher Dichte und Reflowlöten. Verwendet in allen Arten von elektronischen Geräten, Computern, Konvertern.

ML Series0805 ±20%nH 560μH 0.75 Ω 150mA 25 115MHz 25MHz, 200mV MHz

| Größe | Toleranz | Induktivität | DCR (Ω) max. | IDC (mA) | Q | SRF | L/Q Frequenz (MHz) |

|---|---|---|---|---|---|---|---|

| 0805 | ±20% | 560 | 0.75 | 150 | 25 | 115MHz | 25MHz, 200mV |

MLH05 Multilayer Ferrite Chip Inductors Type(□:Tolerance):

| Part No. | Inductance (uH) | Tolerance | Test Freq. | SRF (MHz) min. | DCR (Ω) max. | IDC (mA) max. |

|---|---|---|---|---|---|---|

| MLH05□TR47 | 0.47 | ± 20% | 1MHz, 250mV | 100 | 0.125 | 1100 |

| MLH05□TR68 | 0.68 | ± 20% | 1MHz, 250mV | 100 | 0.150 | 1000 |

| MLH05□TR82 | 0.82 | ± 20% | 1MHz, 250mV | 90 | 0.175 | 900 |

| MLH05□T1R0 | 1.0 | ± 20% | 1MHz, 250mV | 90 | 0.200 | 800 |

| MLH05□T1R2 | 1.2 | ± 20% | 1MHz, 250mV | 80 | 0.200 | 800 |

| MLH05□T1R5 | 1.5 | ± 20% | 1MHz, 250mV | 70 | 0.275 | 700 |

| MLH05□T1R8 | 1.8 | ± 20% | 1MHz, 250mV | 60 | 0.275 | 700 |

| MLH05□T2R2 | 2.2 | ± 20% | 1MHz, 250mV | 50 | 0.313 | 600 |

| MLH05□T3R3 | 3.3 | ± 20% | 1MHz, 250mV | 40 | 0.275 | 500 |

| MLH05□T4R7 | 4.7 | ± 20% | 1MHz, 250mV | 30 | 0.375 | 500 |

☑ Operating temperature range: -40 ~ +125°C

MLH06 Multilayer Ferrite Chip Inductors Type(□:Tolerance):

| Part No. | Inductance (uH) | Tolerance | Test Freq. | SRF (MHz) min. | DCR (Ω) max. | IDC (mA) max. |

|---|---|---|---|---|---|---|

| MLH06□TR47 | 0.47 | ± 20% | 1MHz, 250mV | 100 | 0.182 | 1500 |

| MLH06□TR68 | 0.68 | ± 20% | 1MHz, 250mV | 90 | 0.195 | 1500 |

| MLH06□TR82 | 0.82 | ± 20% | 1MHz, 250mV | 80 | 0.208 | 1500 |

| MLH06□T1R0 | 1.0 | ± 20% | 1MHz, 250mV | 60 | 0.208 | 1400 |

| MLH06□T1R2 | 1.2 | ± 20% | 1MHz, 250mV | 60 | 0.208 | 1400 |

| MLH06□T1R5 | 1.5 | ± 20% | 1MHz, 250mV | 50 | 0.260 | 1200 |

| MLH06□T1R8 | 1.8 | ± 20% | 1MHz, 250mV | 50 | 0.260% | 1200 |

| MLH06□T2R2 | 2.2 | ± 20% | 1MHz, 250mV | 40 | 0.286 | 1200 |

| MLH06□T3R3 | 3.3 | ± 20% | 1MHz, 250mV | 30 | 0.312 | 1100 |

| MLH06□T4R7 | 4.7 | ± 20% | 1MHz, 250mV | 20 | 0.390 | 1100 |

☑ Operating temperature range: -40 ~ +125°C

MLH08 Multilayer Ferrite Chip Inductors Type(□:Tolerance):

| Part No. | Inductance (uH) | Tolerance | Test Freq. | SRF (MHz) min. | DCR (Ω) max. | IDC (mA) max. |

|---|---|---|---|---|---|---|

| MLH08□TR47 | 0.47 | ± 20% | 1MHz, 250mV | 100 | 0.088 | 1800 |

| MLH08□TR68 | 0.68 | ± 20% | 1MHz, 250mV | 90 | 0.113 | 1700 |

| MLH08□TR82 | 0.82 | ± 20% | 1MHz, 250mV | 80 | 0.125 | 1700 |

| MLH08□T1R0 | 1.0 | ± 20% | 1MHz, 250mV | 60 | 0.138 | 1600 |

| MLH08□T1R2 | 1.2 | ± 20% | 1MHz, 250mV | 60 | 0.138 | 1600 |

| MLH08□T1R5 | 1.5 | ± 20% | 1MHz, 250mV | 50 | 0.163 | 1500 |

| MLH08□T1R8 | 1.8 | ± 20% | 1MHz, 250mV | 50 | 0.163 | 1500 |

| MLH08□T2R2 | 2.2 | ± 20% | 1MHz, 250mV | 40 | 0.213 | 1300 |

| MLH08□T3R3 | 3.3 | ± 20% | 1MHz, 250mV | 30 | 0.200 | 1200 |

| MLH08□T4R7 | 4.7 | ± 20% | 1MHz, 250mV | 25 | 0.250 | 1100 |

☑ Operating temperature range: -40 ~ +125°C

Electrical Performance Test

| Item | Requirement | Test Method |

|---|---|---|

| Inductance | Refer to standard electrical characteristic spec. | HP4291B |

| Q | HP4291B | |

| SRF | HP4291B | |

| DC Resistance RDC | Agilent 34401A |

Mechanical Performance Test

| Item | Requirement | Test Method |

|---|---|---|

| Resistance to Soldering Heat | Appearance: No damage More than 75% of the terminal. Electrode should be covered with solder. | Pre-heating: 150°C, 1min. Solder Composition: Sn/Ag3.0/Cu0.5 (Pb-Free) Solder Temperature: 260± 5°C (Pb-Free) Immersion Time: 10± 1 sec. |

| Solderability | The electrodes shall be at least 90% covered with new solder coating | Pre-heating: 150°C, 1min. Solder Composition: Sn/Ag3.0/Cu0.5 (Pb-Free) Solder Temperature: 245± 5°C (Pb-Free) Immersion Time: 4± 1 sec. |

| Flexure Strength | The forces applied on the right conditions must not damage the terminal electrode and the ferrite. |  Test device shall be soldered on the substrate |

| Vibration | Test device shall be soldered on the substrate Oscillation Frequency: 10 to 55 to 10Hz for 1 min. Amplitude: 1.5 mm Time: 2 hrs for each axis (X, Y & Z), total 6 hrs |

Climatic Test

| Item | Requirement | Test Method | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Damp Heat with Load | Appearance: No damage L change: within± 20% of initial value | Temperature: 40± 2°C Relative Humidity: 90 ~ 95% Time: 1000 hrs Measured after exposure in the room condition for 24 hrs | ||||||||||||||

| Temperature Cycle | One cycle:

Total: 100 cycles | |||||||||||||||

| High Temperature Resistance | Temperature: 85± 3°C Relative Humidity: 20% Applied Current: Rated Current Time: 1000 hrs Measured after exposure in the room condition for 24 hrs | |||||||||||||||

| Low Temperature Resistance | Temperature: -40± 3°C Relative Humidity: 0% Time: 1000 hrs Measured after exposure in the room condition for 24 hrs |

☑ Storage Temperature: 15 ~ 28°C; Humidity < 80%RH

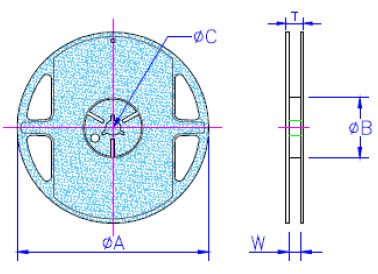

Reel Specifications (Unit : mm)

| Type | A | B | C | W | T | Quantity (EA) | |

|---|---|---|---|---|---|---|---|

| Paper Tape (Type B) | Polystyrene Tape (Type A) | ||||||

| ML03 | 178 ± 1 | 60.0 + 0.5 | 13.0 ± 0.2 | 9.00 ± 0.5 | 12.0 ± 0.15 | 4,000 | - |

| ML05 (≤ 2.2uH) | 178 ± 1 | 60.0 + 0.5 | 13.0 ± 0.2 | 9.00 ± 0.5 | 12.0 ± 0.15 | 4,000 | - |

| ML05 (≥ 2.7uH) | 178 ± 1 | 60.0 + 0.5 | 13.0 ± 0.2 | 9.00 ± 0.5 | 12.0 ± 0.15 | - | 3,000 |

| ML06 | 178 ± 1 | 60.0 + 0.5 | 13.0 ± 0.2 | 9.00 ± 0.5 | 12.0 ± 0.15 | - | 3,000 |

| MLH05 | 178 ± 1 | 60.0 + 0.5 | 13.0 ± 0.2 | 9.00 ± 0.5 | 12.0 ± 0.15 | 4.000 | - |

| MLH06 | 178 ± 1 | 60.0 + 0.5 | 13.0 ± 0.2 | 9.00 ± 0.5 | 12.0 ± 0.15 | - | 3,000 |

| MLH08 | 178 ± 1 | 60.0 + 0.5 | 13.0 ± 0.2 | 9.00 ± 0.5 | 12.0 ± 0.15 | - | 3,000 |

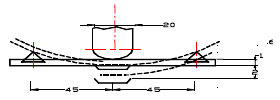

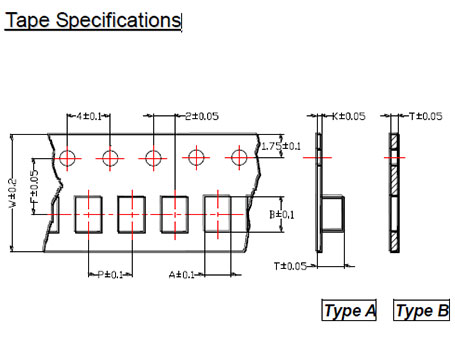

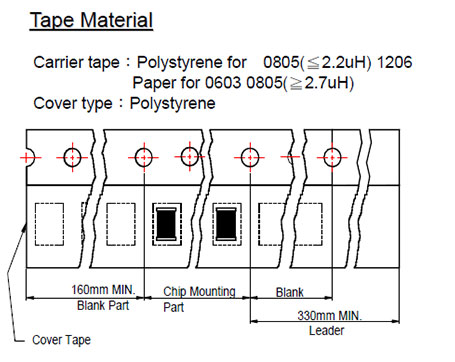

Tape Specifications & Tape Material (Unit : mm)

| Type | A | B | T | W | P | F | K | Tape Type |

|---|---|---|---|---|---|---|---|---|

| ML03 | 1.05 | 1.85 | 0.95 | 8.0 | 4.0 | 3.5 | - | B |

| ML05(≤ 2.2uH) | 1.50 | 2.42 | 0.95 | 8.0 | 4.0 | 3.5 | - | B |

| ML05(≥ 2.7uH) | 1.50 | 2.35 | 1.45 | 8.0 | 4.0 | 3.5 | 0.22 | A |

| ML06 | 1.88 | 3.50 | 1.27 | 8.0 | 4.0 | 3.5 | 0.22 | A |

| MLH05 | 1.45 | 2.25 | 0.95 | 8.0 | 4.0 | 3.5 | - | B |

| MLH06 | 1.88 | 2.40 | 1.23 | 8.0 | 4.0 | 3.5 | 0.23 | A |

| MLH08 | 2.20 | 2.85 | 1.40 | 8.0 | 4.0 | 3.5 | 0.23 | A |

Note:

1. Please make sure that your product is has been evaluated and confirmed against your specifications when our product is mounted to your product.

2. Do not knock nor drop.

3. All the items and parameters in this product specification have been prescribed on the premise that our product is used for the purpose, under the condition and in the environment agreed upon between you and us. You are requested not to use our product deviating from such agreement.

Dünnschicht-Präzisionswiderstand 0,01%, TC2ppm, Drahtbondable, Anti-Korrosiv, MELF. Strommessung, Metall,...

Weiterlesen

Keramische Hochfrequenz-Chip-Induktivitäten, kleine Größe bis 01005. Dünnschicht-, Multilayer-, Drahtgewickelte-,...

Weiterlesen

Multilayer-Keramikkondensatoren bieten hohe Spannung, hohe Frequenz, geringes Rauschen, hohe Q, niedrigen...

Weiterlesen