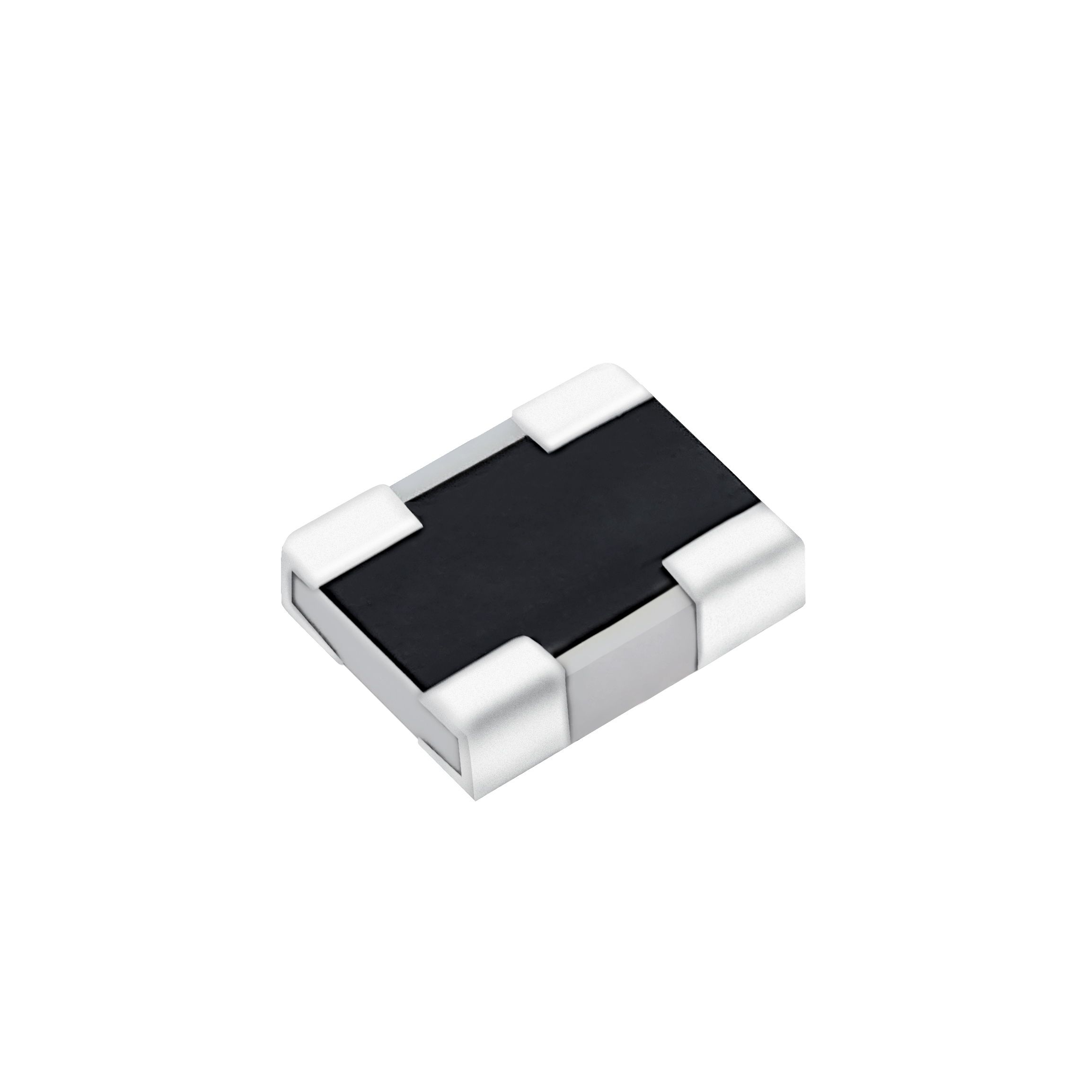

자동차 등급 두꺼운 필름 평면 어레이 칩 저항기 (CNF..A 시리즈 CNF22FTE0150A)

CNF22FTE0150A

자동차 등급 두꺼운 필름 평면 어레이 칩 저항기 - CNF..A 시리즈

CNF..A Series0402 ±1% 200 1/16W Series15Ω 10K/Reel

| 크기 | 허용오차 | TCR (ppm /℃) | 전력 | 저항 (옴) | 패키지 |

|---|---|---|---|---|---|

| 0402 | ±1% | 200 | 1/16W | 15 | 10K/Reel |

등가 회로도

환경 특성

| Item | Requirement | Test Method | ||||

|---|---|---|---|---|---|---|

| ± 1% | ± 5% | Jumper | ||||

| Temperature Coefficient of Resistance (T.C.R.) | As Spec. | JIS-C-5201-1 4.8 IEC-60115-1 4.8 At 25°C/-55°C and 25°C/ + 125°C, 25°C is the reference temperature | ||||

| Short Time Overload | ± (1.0% + 0.05Ω) | ± (2.0% + 0.05Ω) | <50mΩ | JIS-C-5201-1 4.13 IEC-60115-1 4.13 RCWV x 2.5 or Max. Overload Voltage whichever is lower for 5 seconds | ||

| Insulation Resistance | ³10G | JIS-C-5201-1 4.6 IEC-60115-1 4.6 Max. Overload Voltage for 1 minute | ||||

| Operational Life | ± (2.0% + 0.10Ω) | ± (3.0% + 0.10Ω) | <100mΩ | MIL-STD-202 Method 108 Condition D Steady State TA=125°C at derated power. Measurement at 24±4 hours after test conclusion. | ||

| Biased Humidity | ± (2.0% + 0.10Ω) | ± (3.0% + 0.10Ω) | <100mΩ | MIL-STD-202 Method 103 1000 hrs 85°C/85%RH 10% of operating power | ||

| High Temperature Exposure | ± (1.0% + 0.05Ω) | ± (1.5% + 0.10Ω) CN-21/41: ± (3.0% + 0.10Ω) | <50mΩ CN-21/41: <100mΩ | MIL-STD-202 Method 108 at + 155°C for 1000 hrs | ||

| Board Flex | ± (1.0% + 0.05Ω) | ± (1.0% + 0.05Ω) | <50mΩ | AEC-Q200-005 Bending once for 60 seconds with 3mm | ||

| Solderability | 95% min. coverage | JIS-C-5201-1 4.17 IEC-60115-1 4.17 J-STD-002 245± 5°C for 3 seconds | ||||

| Resistance to Soldering Heat | ± (0.5% + 0.05Ω) | ± (1.0% + 0.05Ω) | <50mΩ | MIL-STD-202 Method 210 260± 5°C for 10 seconds | ||

| Voltage Proof | No breakdown or flashover | JIS-C-5201-1 4.7 IEC-60115-1 4.7 1.42 times Max. Operating Voltage for 1 minute | ||||

| Leaching | Individual leaching area ≦5% Total leaching area ≦ 10% | JIS-C-5201-1 4.18 IEC-60068-2-58 8.2.1 260± 5°C for 30 seconds | ||||

| Temperature Cycling | ± (0.5% + 0.05Ω) | ± (1.5% + 0.05Ω) | <50mΩ | JESD22 Method JA-104 -55°C to + 125°C, 1000 cycles | ||

| Mechanical Shock | ± (0.25% + 0.05Ω) | ± (1.0% + 0.05Ω) | <50mΩ | MIL-STD-202 Method 213 Wave Form: Tolerance for half sine shock pulse. Peak value is 100g's. Normal duration (D) is 6. | ||

| Vibration | ± (0.5% + 0.05Ω) | ± (1.0% + 0.05Ω) | <50mΩ | MIL-STD-202 Method 204 5 g's for 20 min., 12 cycles each of 3 orientations, 10-2000 Hz | ||

| ESD | ± (1% + 0.05Ω) | AEC-Q200-002 Human body, 2KV | ||||

| Resistance to Solvents | No visible damage on appearance and marking. | MIL-STD-202 Method 215 Add Aqueous wash chemical - OKEM Clean or equivalent. Do not use banned solvents. | ||||

| Terminal Strength | No broken | AEC-Q200-006 Force of 1.8kg for 60 seconds. | ||||

| Flammability | No ignition of the tissue paper or scorching or the pinewood board | UL-94 V-0 or V-1 are acceptable. Electrical test not required. | ||||

| Sulfur Test | ± R± 5% | <100mΩ | EIA-977 (Condition A) 60± 2°C, no power rating for 480 hrs. | |||

RCWV (Rated Continuous Working Voltage)=√(P x R) or Max. Operating Voltage whichever is lower.

☑ Storage Temperature: 15~28°C; Humidity < 80%RH

납땜 조건

마킹

No Marking for CN-21 / CN-41

Jumper for all: Letter "0"

1% for CN-42 / CN-43: 4 digits marking (non-including E24 series)

Example:

| Resistance | 102Ω | 2.49KΩ | 30K1Ω | 49.9KΩ | 121KΩ |

|---|---|---|---|---|---|

| marking | 1020 | 2491 | 3012 | 4992 | 1213 |

5% for CN-42 / CN-43: 3 digits marking in E24

Example: 101=100Ω 102=1KΩ (1st and 2nd are E24 code and 3rd code is multiplier)

| E24 code | 10 | 11 | 12 | 13 | 15 | 16 | 18 | 20 | 22 | 24 | 27 | 30 | 33 | 36 | 39 | 43 | 47 | 51 | 56 | 62 | 68 | 75 | 82 | 91 |

포장

Reel Specifications & Packaging Quantity

| Type | Packaging Quantity | Tape Width | Reel Diameter | ΦA (mm) | ΦB (mm) | ΦC (mm) | W (mm) | T (mm) | |

|---|---|---|---|---|---|---|---|---|---|

| CN-21 CN-41 | Paper | 10K | 8mm | 7 inch | 178.5 ± 1.5 | 60 + 1/-0 | 13.0 ± 0.2 | 9.0 ± 0.5 | 12.5 ± 0.5 |

| CN-42 | Paper | 10K | 8mm | 7 inch | 178.5 ± 1.5 | 60 + 1/-0 | 13.0 ± 0.2 | 9.0 ± 0.5 | 12.5 ± 0.5 |

| 20K | 8mm | 10 inch | 254 ± 1.0 | 100 ± 0.5 | 13.0 ± 0.2 | 9.5 ± 0.5 | 13.5 ± 0.5 | ||

| 40K | 8mm | 13 inch | 330 ± 1.0 | 100 ± 0.5 | 13.0 ± 0.2 | 9.5 ± 0.5 | 13.5 ± 0.5 | ||

| CN-43 | Paper | 5K | 8mm | 7 inch | 178.5 ± 1.5 | 60 + 1/-0 | 13.0 ± 0.2 | 9.0 ± 0.5 | 12.5 ± 0.5 |

| 10K | 8mm | 10 inch | 254 ± 1.0 | 100 ± 0.5 | 13.0 ± 0.2 | 9.5 ± 0.5 | 13.5 ± 0.5 | ||

| 20K | 8mm | 13 inch | 330 ± 1.0 | 100 ± 0.5 | 13.0 ± 0.2 | 9.5 ± 0.5 | 13.5 ± 0.5 | ||

Paper Tape Specifications

| Type | A (mm) | B (mm) | W (mm) | E (mm) | F (mm) | P0 (mm) | P1 (mm) | P2 (mm) | ΦD0 (mm) | T (mm) |

|---|---|---|---|---|---|---|---|---|---|---|

| CN-21 | 0.77 ± 0.05 | 0.97 ± 0.05 | 8.0 ± 0.2 | 1.75 ± 0.1 | 3.5 ± 0.05 | 4.0 ± 0.1 | 2.0 ± 0.05 | 2.0 ± 0.05 | 1.50 + 0.1, -0 | 0.50 ± 0.1 |

| CN-41 | 0.77 ± 0.05 | 1.57 ± 0.05 | 8.0 ± 0.2 | 1.75 ± 0.1 | 3.5 ± 0.05 | 4.0 ± 0.1 | 2.0 ± 0.05 | 2.0 ± 0.05 | 1.50 + 0.1, -0 | 0.50 ± 0.1 |

| CN-42 | 1.20 ± 0.1 | 2.20 ± 0.1 | 8.0 ± 0.2 | 1.75 ± 0.1 | 3.5 ± 0.05 | 4.0 ± 0.1 | 2.0 ± 0.05 | 2.0 ± 0.05 | 1.50 + 0.1, -0 | 0.70 ± 0.1 |

| CN-43 | 1.95 ± 0.1 | 3.50 ± 0.1 | 8.0 ± 0.2 | 1.75 ± 0.1 | 3.5 ± 0.05 | 4.0 ± 0.1 | 4.0 ± 0.05 | 2.0 ± 0.05 | 1.50 + 0.1, -0 | 0.85 ± 0.1 |

코드

- 0150

베스트 판매

주요 제품