シールド付きSMD電源インダクタ (PCSシリーズ PCS73MT120)

PCS73MT120

シールド付きSMDパワーインダクタ、コンパクトで低プロファイル、低DCRと大電流、放射線に対して磁気シールドされています。

PCS Series73 ±20% 12μH 0.098 Ω 1.52A

| サイズ | 公差 | インダクタンス | DCR (Ω) 最大 | IDC (A) |

|---|---|---|---|---|

| 73 | ±20% | 12 | 0.098 | 1.52 |

高電流電気仕様

PCSH127 Type(□:Tolerance)

| Part No. | L (μH) | Tolerance | Test Condition | DCR (Ω) Max | IDC (A) Max |

|---|---|---|---|---|---|

| PCSH127□T2R2 | 2.2 | N | 100KHz, 0.25V | 0.007 | 25.5 |

| PCSH127□T4R7 | 4.7 | N | 100KHz, 0.25V | 0.016 | 15.9 |

| PCSH127□T5R6 | 5.6 | N | 100KHz, 0.25V | 0.020 | 14.0 |

| PCSH127□T6R8 | 6.8 | N | 100KHz, 0.25V | 0.021 | 13.3 |

| PCSH127□T8R2 | 8.2 | N | 100KHz, 0.25V | 0.023 | 12.2 |

| PCSH127□T100 | 10 | M | 100KHz, 0.25V | 0.024 | 11.2 |

| PCSH127□T150 | 15 | M | 100KHz, 0.25V | 0.031 | 9.00 |

| PCSH127□T180 | 18 | M | 100KHz, 0.25V | 0.035 | 7.70 |

| PCSH127□T220 | 22 | M | 100KHz, 0.25V | 0.040 | 7.57 |

| PCSH127□T330 | 33 | M | 100KHz, 0.25V | 0.070 | 6.22 |

| PCSH127□T390 | 39 | M | 100KHz, 0.25V | 0.075 | 5.40 |

| PCSH127□T470 | 47 | M | 100KHz, 0.25V | 0.080 | 5.28 |

| PCSH127□T560 | 56 | M | 100KHz, 0.25V | 0.130 | 4.50 |

| PCSH127□T680 | 68 | M | 100KHz, 0.25V | 0.105 | 4.26 |

| PCSH127□T820 | 82 | M | 100KHz, 0.25V | 0.143 | 3.80 |

| PCSH127□T101 | 100 | M | 100KHz, 0.25V | 0.163 | 3.52 |

| PCSH127□T121 | 120 | M | 100KHz, 0.25V | 0.170 | 3.20 |

| PCSH127□T151 | 150 | M | 100KHz, 0.25V | 0.247 | 3.01 |

| PCSH127□T221 | 220 | M | 100KHz, 0.25V | 0.376 | 2.36 |

| PCSH127□T331 | 330 | M | 100KHz, 0.25V | 0.574 | 2.00 |

| PCSH127□T391 | 390 | M | 100KHz, 0.25V | 0.650 | 1.50 |

| PCSH127□T471 | 470 | M | 100KHz, 0.25V | 0.861 | 1.64 |

| PCSH127□T681 | 680 | M | 100KHz, 0.25V | 1.080 | 1.38 |

| PCSH127□T821 | 820 | M | 100KHz, 0.25V | 1.470 | 1.26 |

| PCSH127□T102 | 1000 | M | 100KHz, 0.25V | 1.660 | 1.14 |

■Viking is capable to design according to customer special requirement

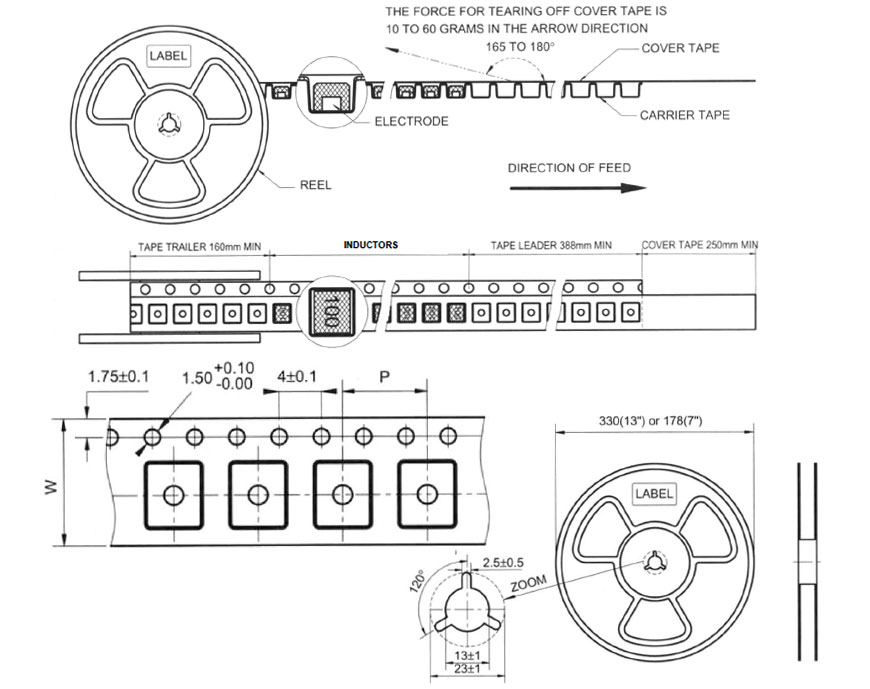

テープおよびリール仕様(単位:mm)

| Type | Tape Size | Parts Per Reel | |

|---|---|---|---|

| W | P | 13" | |

| PCS62B | 16 | 12 | 1500 |

| PCS64B | 16 | 12 | 1000 |

| PCS73 | 16 | 12 | 1000 |

| PCS74 | 16 | 12 | 1000 |

| PCS124 | 24 | 16 | 500 |

| PCS125 | 24 | 16 | 400 |

| PCS127 | 24 | 16 | 400 |

| PCS129 | 24 | 16 | 300 |

| PCSH127 | 24 | 16 | 500 |

SMT電源インダクタの環境仕様

General

| Item | Specification |

|---|---|

| Shelf Storage conditions | Temperature range: 15 ~ 28°C; Humidity: <80% relative humidity. Recommended product should be used within one year from the time of delivery. |

Environmental Test

| Test Items | Specification | Test Conditions / Test Methods |

|---|---|---|

| High temperature Storage test | No case deformation or change in appearance. Δ L/L ≤10% |

Temperature 85 ± 2°C, Time: 48 ± 2 hours, Tested after 1hour at room temperature. |

| Low temperature Storage test | Temperature -25 ± 2°C, Time: 48 ± 2 hours, Tested after 1hour at room temperature. |

|

| Humidity test | Temperature 40 ± 2°C, 90 ~ 95% relative humidity Time: 96 ± 2 hours Tested after 1hour at room temperature. |

|

| Thermal shock test | First -25°C 30minutes then 25°C 10 minutes last 85°C 30 minutes, as 1 cycle. Go through 5 cycles. Tested after 1 hour at room temperature. |

Mechanical Test

| Test Items | Specification | Test Conditions / Test Methods |

|---|---|---|

| Solder Ability Test | Terminal area must have 90% minimum solder coverage. | Dip pads in flux then dip in solder pot (SnCuNi) at 245 ± 5°C for 3 seconds. |

| Resistance to Soldering Heat | No case deformation or change in appearance. | Flux should cover the whole of the sample before heating, then be preheated for about 2 minutes over temperature of 130 ~ 150°C. Immersing to 260 ± 5°C for 10 seconds. |

| Vibration test | No case deformation or change in appearance. Δ L/L ≤10% |

Apply frequency 10 ~ 55Hz. 1.5mm amplitude in each of perpendicular direction for 2 hours. |

| Shock resistance | Drop down with 981m/s² (100G) shock attitude upon a rubber block method shock testing machine, for 1 time. In each of three orientations. |

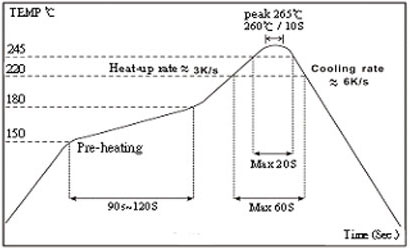

リフロー

The Condition Of Reflow (Recommendation):

コード

- 120

主な製品