チップ共通モードチョーク(CMシリーズ CMH06MT222)

CMH06MT222

チップ共通モードフィルタは、フェライトコアと2本の線タイプのワイヤで巻かれた小型チップインダクタです。ノイズ帯域での高い共通モードインピーダンスによるノイズ抑制効果があり、信号帯域での低い差動モードインピーダンス、高い結合係数による低い差動モードインピーダンスがあります。高速信号ではほとんど歪みがありません。一般的には、任意の電子機器のEMI放射ノイズ抑制に使用されます。

CM Series1206 ±20% 2200μH 1.2 Ω 200mA 125V 10MΩ min.

| サイズ | 公差 | インダクタンス | 試験条件 | DCR (Ω) 最大 | IDC (mA) | 定格電圧 | 耐圧 Vdc (V) | 絶縁抵抗 (MΩ) 最小。 |

|---|---|---|---|---|---|---|---|---|

| 1206 | ±20% | 2200 | 100MHz | 1.2 | 200 | 50 | 125 | 10 |

環境特性

Electrical Performance Test

| Items | Requirement | Test Conditions / Test Methods |

|---|---|---|

| Impedance | Refer to standard electrical characteristic spec. Component should not be damaged |

LCR Meter HP 4291B |

| DC Resistance DCR | Micro-Ohm meter (GOM-801G) | |

| Withstand Voltage (VDC) | Test Voltage: 2.5 Times Rated Voltage Testing Time: 60 seconds Charge Current: 0.5mA |

|

| Rated Voltage (VDC) | Test Voltage: Rated Voltage Testing Time: 1 to 5 seconds Charge Current: 1mA |

|

| Insulation Resistance (I.R) | Charge Current: 1minute 10M ohm min. |

Mechanical Performance Test

| Items | Requirement | Test Conditions / Test Methods |

|---|---|---|

| Component Adhesion (Push Test) |

Base: 0805≧2 Lbs Cover: 0805≧1 Lbs Base: 1206≧4 Lbs Cover: 1206≧2 Lbs |

The component should be soldered (232°C± 5°C for 10 sec.) to tinned copper substrate Applied force gauge to the side of component It must withstand force of 2 or 4 pounds without failure of the component. |

| Drop | Component should not be damaged | Dropping chip by each side and corner. Drop 10 times in total Drop height: 100 cm Drop weight: 125 g |

| Solderability | The terminal should at least be 90% covered with solder | The component shall be dipped in a melted solder bath at 245 ±5℃ for 3 seconds |

| Vibration Test (Low Frequency) | Component should not be damaged | 1. Amplitude: 1.5 m/m 2. Frequency: 10-55-10Hz (1min.) 3. Direction: X, Y, Z 4. Duration: 2 Hrs/X, Y, Z |

Climatic Test

| Items | Requirement | Test Conditions / Test Methods |

|---|---|---|

| Low Temperature Storage | Impedance change: Within± 20% Without distinct damage in appearance |

1. Temp: -40 ±2°C 2. Time: 1000±48 Hours 3. Component should be tested after 1hour at room temperature |

| Thermal Shock |  Total: 5 Cycles |

|

| High Temperature Storage | 1. Temp: 85 ± 2°C 2. Time: 1000 ± 48 Hours 3. Component should be tested after 1hour at room temperature |

|

| Humidity | 1. Temp: 40 ± 2°C 2. R.H. : 90 ~ 95% 3. Time: 48 ±2 Hours |

|

| High Temperature Load Life | There should be no evidence of short or open circuit | 1. Temp: 85 ± 2°C 2. Time: 96 ± 12 Hours 3. Load: Allowed DC Current |

| Low Temperature Load Life | 1. Temp: -40 ± 2°C 2. Time: 96 ± 12 Hours 3. Load: Allowed DC Current |

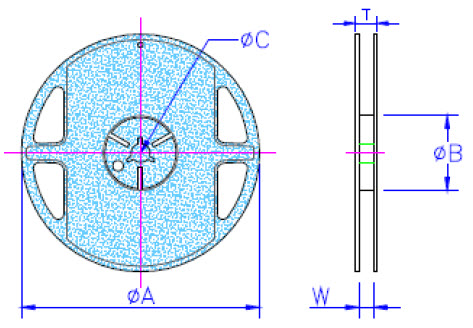

パッケージング

Packaging Quantity & Reel Specifications

| Type | ΦA | ΦB | ΦC | W | T | Quantity (EA) |

|---|---|---|---|---|---|---|

| CMH05 | 178±2.0 | 60±0.5 | 13±0.3 | 9±0.3 | 11.4±1.0 | 2000 |

| CMH06 | 178±2.0 | 60±0.5 | 13±0.3 | 9±0.3 | 11.4±1.0 | 2000 |

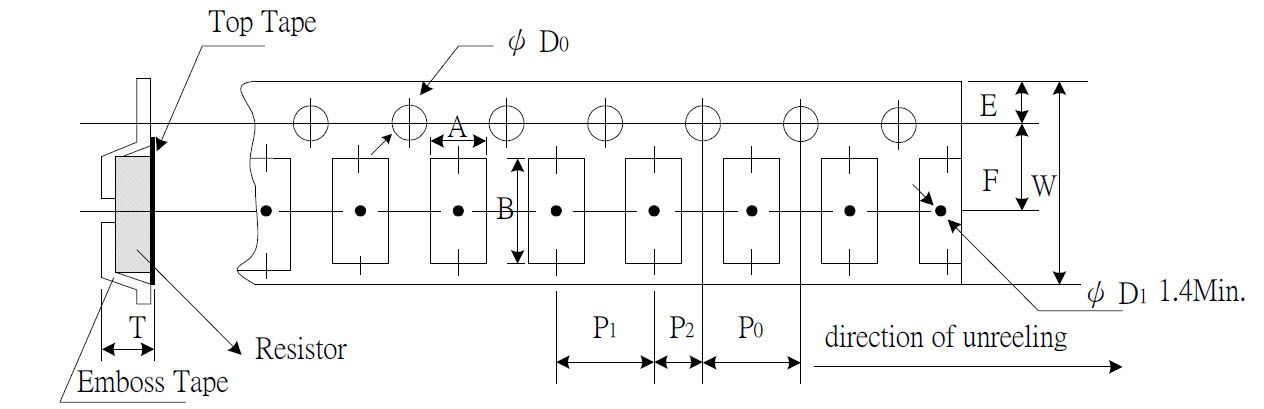

Embossed Plastic Tape Specifications

| Type | A (mm) | B (mm) | W (mm) | E (mm) | F (mm) | P0 (mm) | P1 (mm) | P2 (mm) | ΦD0 (mm) | T (mm) |

|---|---|---|---|---|---|---|---|---|---|---|

| CMH05 | 1.40±0.10 | 2.55±0.05 | 8.0±0.20 | 1.75±0.10 | 3.5±0.10 | 4.00±0.10 | 4.00±0.10 | 2.00±0.10 | 1.50+0.10 | 1.35±0.10 |

| CMH06 | 1.90±0.10 | 3.50±0.05 | 8.0±0.20 | 1.75±0.10 | 3.5±0.10 | 4.00±0.10 | 4.00±0.10 | 2.00±0.10 | 1.50+0.10 | 2.10±0.10 |

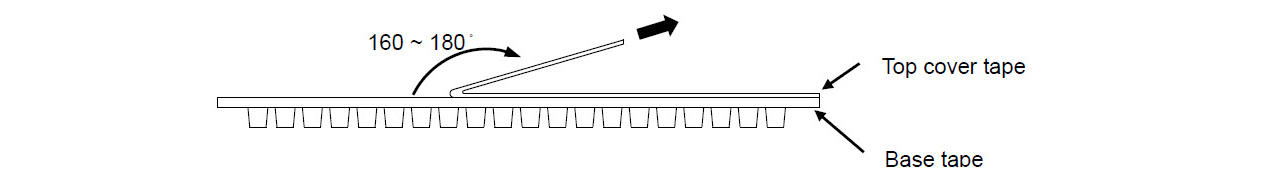

Peel-off Force

The force for tearing off cover tape is 0.05~0.69 (N) in the arrow direction at the following conditions:

Temperature: 5 ~ 35°C

Humidity: 45 ~ 85%

Atmospheric pressure: 860 ~ 1060hpa

ベストセール

主な製品