AUTOMOTIVE APPLICATIONS

Thin film Precision resistor 0.01%, TC2ppm, wirebondale, Anti-Crossive, MELF. Current sensing, Metal...

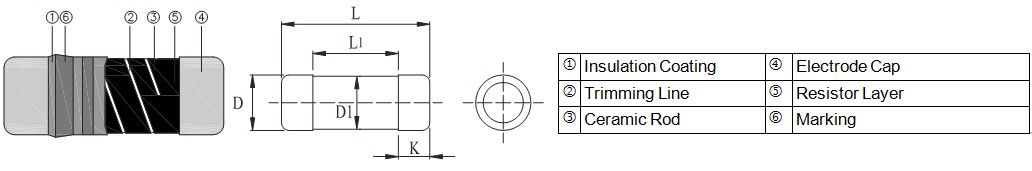

Read MoreThe MELF is cylindrical in shape and with metal electrode Leadless face resistor. Land pattern sizes are the same as SMD chip resistors.

It is manufactured by depositing a homogeneous film of NiCr onto a high-grade ceramic body. High quality of MELF resistors offer excellent electrical and Environmental Stability, exceptional stability demonstrated over life, biased humidity, and short time overload testing.

Short lead time, Effective cost control, price competitiveness

| DESCRIPTION | CSRV0102 | CSRV0204 | CSRV0207 | ||||

|---|---|---|---|---|---|---|---|

| Resistance range | 1Ω - 1MΩ; 0Ω | 0.1Ω - 3.4MΩ; 0Ω | 0.1Ω - 3.4MΩ; 0Ω | ||||

| Resistance tolerance | ± 5%;± 1%;± 0.5%;± 0.25%;± 0.1% | ||||||

| Temperature coefficient | ± 100ppm/°C; ± 50ppm/°C; ± 25ppm/°C; ± 15ppm/°C | ± 100ppm/°C; ± 50ppm/°C; ± 25ppm/°C; ± 15ppm/°C; ± 10ppm/°C | |||||

| Operation mode | Standard | High power | Standard | High power | Standard | High power | |

| Power rating P70 | 1/8W | 1/5W | 0.3W | 1/4W | 2/5W | 1/2W | 1W |

| Operating voltage Umax. | 150V | 200V | 200V | 200V | 200V | 300V | 350V |

| Operating temperature range | -55°C ~ 155°C | ||||||

| Max. resistance change at P70 for resistance range, ΔR/R max., after 1000 h | ≦ 0.5% | ≦ 0.5% | ≦ 0.5% | ||||

| Item Type | Power Rating at 70°C | Operating Temp. Range | Max. Operating Voltage | Max. Overload Voltage | Resistance Range | TCR (PPM/°C) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ± 0.1% (E24,E96) | ± 0.25% (E24,E96) | ± 0.5% (E24,E96) | ± 1% (E24,E96) | ± 5% (E24) | |||||||||

| 0102 | 1/8W | -55 ~ +155°C | 150V | 300V | 100Ω - 56KΩ | - | ± 15 | ||||||

| 100Ω - 82KΩ | 49.9Ω- 200KΩ | 49.9Ω - 390KΩ | - | ± 25 | |||||||||

| - | 8.2Ω - 1MΩ | ± 50 | |||||||||||

| - | 40Ω - 1MΩ | ± 100 | |||||||||||

| Jumper:2A | 0Ω (<15mΩ) | - | |||||||||||

| 0204 | 1/4W | -55 ~ +155°C | 200V | 400V | 49.9Ω - 20KΩ | ± 10 | |||||||

| 10Ω - 300KΩ | ± 15 | ||||||||||||

| 10Ω - 1MΩ | 10Ω - 3.4MΩ | 4.02Ω - 3.4MΩ | ± 25 | ||||||||||

| 10Ω - 1MΩ | 1Ω - 1MΩ | 1Ω - 3.4MΩ | 0.2Ω - 3.4MΩ | ± 50 | |||||||||

| - | 0.1Ω-1MΩ | ± 100 | |||||||||||

| Jumper:3A | 0Ω (<15mΩ) | - | |||||||||||

| 0207 | 1/2W | -55 ~ +155°C | 300V | 600V | 49.9Ω - 20KΩ | ± 10 | |||||||

| 10Ω - 300KΩ | ± 15 | ||||||||||||

| 10Ω - 1MΩ | 10Ω - 3.4MΩ | 4.02Ω - 3.4MΩ | ± 25 | ||||||||||

| 10Ω - 1MΩ | 1Ω - 1MΩ | 1Ω - 3.4MΩ | 0.2Ω - 3.4MΩ | ± 50 | |||||||||

| - | 0.1Ω - 1MΩ | ± 100 | |||||||||||

| Jumper:5A | 0Ω (<15mΩ) | - | |||||||||||

The single impulse graph is the result of the impulse of rectangular shape applied. The limit of acceptance was a shift in resistance of less than 1% from the initial value. The power applied was subject to the restrictions of the maximum permissible impulse voltage graph shown.

The continuous load graph was obtained by applying repetitive rectangular pulses where the pulse period was adjusted so that the average power dissipated in the resistor was equal to its rated power at 70℃. Again the limit of acceptance was a shift in resistance of less than 1% from the initial value.

Resistors are designed to function according to ohmic laws. This is basically true of resistors for frequencies up to 100kHz. At higher frequencies, there is an additional contribution to the impedance by an ideal resistor switched in series with a coil and both switched parallel to a capacitor. The values of the capacitance and inductance are mainly determined by the dimensions of the terminations and the conductive path length.

The environment surrounding components has a large influence on the behavior of the component on the printed-circuit board.

Resistors are tested in accordance with IEC 60115-1 using both 1.2/50us and 10/700us pulse shapes. The limit of acceptance is a shift in resistance of less than 0.5% from the initial value.

Thin film Precision resistor 0.01%, TC2ppm, wirebondale, Anti-Crossive, MELF. Current sensing, Metal...

Read More

Ceramic high frequency chip inductors, small size to 01005. Thin film, multilayer, wirewound , ferrite...

Read More

Multilayer Ceramic capacitor offers high Voltage, high frequency, low noise, High Q, Low TCR. NPO, X7R,...

Read More