AUTOMOBILANWENDUNGEN

Dünnschicht-Präzisionswiderstand 0,01%, TC2ppm, Drahtbondable, Antikorrosiv, MELF. Stromsensoren, Metall,...

WeiterlesenAllgemeiner Dickschicht-Strommeßwiderstand, Standard-TC, kostengünstig für große Nachfrage in der Leistungssteuerung.

RS Series2010 ±5% 1500 1W Series10mΩ

| Größe | Toleranz | TCR (ppm /℃) | Leistung | Widerstand (Ohm) |

|---|---|---|---|---|

| 2010 | ±5% | 1500 | 1W | 10m |

| Item Type |

Power Rating at 70°C |

Operating Temp. Range |

Max. Operating Current |

Resistance Range (mΩ) | TCR (PPM/°C) |

|

|---|---|---|---|---|---|---|

| ±1% | ±5% | |||||

| RS-02 (0402) | 1/10W | -55 ~ +155°C | 1.40A | 50 - 91 100 - 976 |

±800 ±500 |

|

| RS-03 (0603) | 1/8W | -55 ~ +155°C | 2.50A | 20 - 47 50 - 91 100 - 976 |

±1200 ±800 ±500 |

|

| RS-05 (0805) | 1/4W | -55 ~ +155°C | 5.00A | 10 - 18 20 - 47 50 - 91 100 - 976 |

±1500 ±1200 ±800 ±500 |

|

| RS-06 (1206) | 1/2W | -55 ~ +155°C | 7.07A | |||

| RS-10 (1210) | 1/2W | -55 ~ +155°C | 7.07A | 10 - 18 20 - 91 100 - 976 |

±1500 ±800 ±500 |

|

| RS-0A (2010) | 1W | -55 ~ +155°C | 10.0A | |||

| RS-12 (2512) | 2W | -55 ~ +155°C | 14.1A | |||

Operating Voltage=√(P*R)

Overload Voltage=2.5*√(P*R)

Operating Current=√(P/R)

☑ Viking is capable of manufacturing the optional spec based on customer's requirement.

| Item | Requirement | Test Method | |

|---|---|---|---|

| ±1% | ±5% | ||

| Temperature Coefficient of Resistance (T.C.R.) |

As Spec. | JIS-C-5201-1 4.8 IEC-60115-1 4.8 -55°C~+125°C, 25°C is the reference temperature |

|

| Short Time Overload | ±(1.0%+0.05Ω) | ±(2.0%+0.05Ω) | JIS-C-5201-1 4.13 IEC-60115-1 4.13 RCWV*2.5 or Max. Overload Voltage whichever is lower for 5 seconds, 2 seconds for High Power Series |

| Insulation Resistance | ≥10G | JIS-C-5201-1 4.6 IEC-60115-1 4.6 Max. Overload Voltage for 1 minute |

|

| Endurance | ±(1.0%+0.10Ω) | ±(2.0%+0.10Ω) | JIS-C-5201-1 4.25 IEC-60115-1 4.25.1 70±2°C, RCWV for 1000 hrs with 1.5 hrs “ON” and 0.5 hr “OFF” |

| Damp Heat with Load | ±(1.0%+0.10Ω) | ±(2.0%+0.10Ω) | JIS-C-5201-1 4.24 IEC-60115-1 4.24 40±2°C, 90~95% R.H., RCWV for 1000 hrs with 1.5 hrs “ON” and 0.5 hr “OFF” |

| Dry Heat | ±(1.0%+0.05Ω) | ±(1.5%+0.10Ω) | JIS-C-5201-1 4.23 IEC-60115-1 4.23.2 at +155°C for 1000 hrs |

| Bending Strength | ±(1.0%+0.05Ω) | ±(1.0%+0.05Ω) | JIS-C-5201-1 4.33 IEC-60115-1 4.33 Bending once for 5 seconds 2010, 2512 sizes: 2mm Other sizes: 3mm |

| Solderability | 95% min. coverage | JIS-C-5201-1 4.17 IEC-60115-1 4.17 245±5°C for 3 seconds |

|

| Resistance to Soldering Heat | ±(0.5%+0.05Ω) | ±(1.0%+0.05Ω) | JIS-C-5201-1 4.18 IEC-60115-1 4.18 260±5°C for 10 seconds |

| Voltage Proof | No breakdown or flashover | JIS-C-5201-1 4.7 IEC-60115-1 4.7 1.42 times Max. Operating Voltage for 1 minute |

|

| Leaching | Individual leaching area ≦5% Total leaching area ≦ 10% |

JIS-C-5201-1 4.18 IEC-60068-2-58 8.2.1 260±5°C for 30 seconds |

|

| Rapid Change of Temperature | ±(0.5%+0.05Ω) | ±(1.0%+0.05Ω) | JIS-C-5201-1 4.19 IEC-60115-1 4.19 -55°C to +155°C, 5 cycles |

RCWV(Rated Continuous Working Voltage)=√(P*R) or Max. Operating Voltage whichever is lower.

☑ Storage Temperature: 15~28°C; Humidity < 80%RH

No Marking for 0402

1%, 5% for 0805/1206/1210/2010/2512: 4 digits marking

Example:

| Resistance | 47mΩ | 75mΩ | 15mΩ | 750mΩ | 820mΩ |

|---|---|---|---|---|---|

| Marking | R047 | R075 | R015 | R750 | R820 |

5% for 0603: 3 digits marking in E24

1% for 0603: 3 digits marking with under-line in E96 (non-including E24 series)

3 digits marking for E24 or R value suffix is zero in E96: R10=100mΩ; R28=280mΩ,

3 digits marking for E96: 243=243mΩ; 511=511mΩ

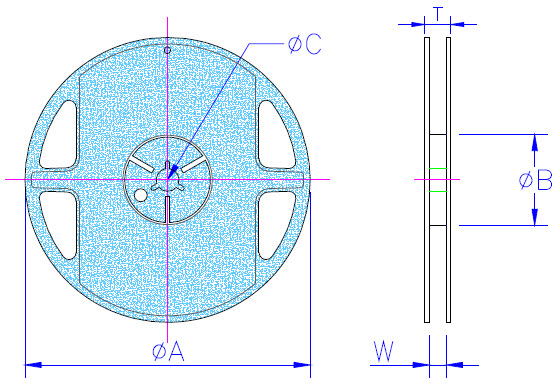

Packing Quantity & Reel Specifications

| Type | Packaging Quantity |

Tape Width |

Reel Diameter |

ΦA (mm) |

ΦB (mm) |

ΦC (mm) |

W (mm) |

T (mm) |

|

|

|---|---|---|---|---|---|---|---|---|---|---|

| RS-02 | Paper | 10K | 8mm | 7 inch | 178.5±1.5 | 60+1/-0 | 13.0±0.2 | 9.0±0.5 | 12.5±0.5 | |

| 20K | 8mm | 10 inch | 254±1.0 | 100±0.5 | 13.0±0.2 | 9.5±0.5 | 13.5±0.5 | |||

| 40K | 8mm | 13 inch | 330±1.0 | 100±0.5 | 13.0±0.2 | 9.5±0.5 | 13.5±0.5 | |||

| RS-03 RS-05 RS-06 RS-10 |

Paper | 5K | 8mm | 7 inch | 178.5±1.5 | 60+1/-0 | 13.0±0.2 | 9.0±0.5 | 12.5±0.5 | |

| 10K | 8mm | 10 inch | 254±1.0 | 100±0.5 | 13.0±0.2 | 9.5±0.5 | 13.5±0.5 | |||

| 20K | 8mm | 13 inch | 330±1.0 | 100±0.5 | 13.0±0.2 | 9.5±0.5 | 13.5±0.5 | |||

| RS-0A RS-12 |

Embossed | 4K | 12mm | 7 inch | 178.5±1.5 | 60+1/-0 | 13.0±0.5 | 13.0±0.5 | 15.5±0.5 | |

| 8K | 12mm | 10 inch | 250±1.0 | 62±0.5 | 13.0±0.5 | 12.5±0.5 | 16.5±0.5 | |||

Paper Tape Specifications

| Type | A (mm) |

B (mm) |

W (mm) |

E (mm) |

F (mm) |

P0 (mm) |

P1 (mm) |

P2 (mm) |

ΦD0 (mm) |

T (mm) |

|---|---|---|---|---|---|---|---|---|---|---|

| RS-02 | 0.65±0.10 | 1.15±0.10 | 8.0±0.20 | 1.75±0.10 | 3.50±0.05 | 4.00±0.10 | 2.00±0.05 | 2.00±0.05 | 1.50+0.1,-0 | 0.45±0.10 |

| RS-03 | 1.10±0.10 | 1.90±0.10 | 8.0±0.20 | 1.75±0.10 | 3.50±0.05 | 4.00±0.10 | 4.00±0.05 | 2.00±0.05 | 1.50+0.1,-0 | 0.70±0.10 |

| RS-05 | 1.60±0.10 | 2.40±0.20 | 8.0±0.20 | 1.75±0.10 | 3.50±0.05 | 4.00±0.10 | 4.00±0.05 | 2.00±0.05 | 1.50+0.1,-0 | 0.85±0.10 |

| RS-06 | 1.90±0.10 | 3.50±0.20 | 8.0±0.20 | 1.75±0.10 | 3.50±0.05 | 4.00±0.10 | 4.00±0.05 | 2.00±0.05 | 1.50+0.1,-0 | 0.85±0.10 |

| RS-10 | 2.90±0.10 | 3.50±0.20 | 8.0±0.20 | 1.75±0.10 | 3.50±0.05 | 4.00±0.10 | 4.00±0.05 | 2.00±0.05 | 1.50+0.1,-0 | 0.85±0.10 |

Embossed Plastic Tape Specifications

| Type | A (mm) |

B (mm) |

W (mm) |

E (mm) |

F (mm) |

P0 (mm) |

P1 (mm) |

P2 (mm) |

ΦD0 (mm) |

T (mm) |

|---|---|---|---|---|---|---|---|---|---|---|

| RS-0A | 2.8±0.10 | 5.5±0.10 | 12.0±0.30 | 1.75±0.10 | 5.5±0.05 | 4.00±0.10 | 4.00±0.10 | 2.00±0.05 | 1.50+0.1, -0 | 1.2+0 |

| RS-12 | 3.5±0.10 | 6.7±0.10 | 12.0±0.30 | 1.75±0.10 | 5.5±0.05 | 4.00±0.10 | 4.00±0.10 | 2.00±0.05 | 1.50+0.1, -0 | 1.2+0 |

Dünnschicht-Präzisionswiderstand 0,01%, TC2ppm, Drahtbondable, Antikorrosiv, MELF. Stromsensoren, Metall,...

Weiterlesen

Keramische Hochfrequenz-Chip-Induktoren, klein bis 01005. Dünnschicht-, Mehrschicht-, Drahtgewickelte-,...

Weiterlesen

Mehrschicht-Keramikkondensator bietet hohe Spannung, hohe Frequenz, geringes Rauschen, hohe Güte, niedrige...

Weiterlesen