AUTOMOBILANWENDUNGEN

Dünnschicht-Präzisionswiderstand 0,01%, TC2ppm, Drahtbondable, Antikorrosiv, MELF. Stromsensoren, Metall,...

WeiterlesenDrahtgewickelter Ferrit-Chip-Hochleistungsinduktor, kleine Größen, geschlossener magnetischer Kreis vermeidet Übersprechen, geeignet für die Installation mit hoher Dichte und Reflow-Löten. Verwendet in allen Arten von elektronischen Geräten, Computern, Konvertern.

MLP Series1008 ±20% 1μH 0.044 Ω 4.3A 3.3A

| Größe | Toleranz | Induktivität | Testbedingungen | DCR (Ω) max. | I sat (A) max. | I rms (A) max. |

|---|---|---|---|---|---|---|

| 1008 | ±20% | 1 | 1MHz, 1mA | 0.044 | 4.3 | 3.3 |

MLPH06 (0806) Wire Wound Type Power Inductor

| Codes | Inductance (uH) | Tolerance | Test Condition | DCR (mΩ) max. | Isat (A) max. | Irms (A) max. |

|---|---|---|---|---|---|---|

| R47 | 0.47 | ± 20% | 1MHz, 1V | 30 | 5.30 | 4.05 |

| 1R0 | 1.0 | ± 20% | 1MHz, 1V | 60 | 3.30 | 3.00 |

| 1R5 | 1.5 | ± 20% | 1MHz, 1V | 99 | 3.10 | 2.20 |

| 2R2 | 2.2 | ± 20% | 1MHz, 1V | 140 | 2.45 | 2.00 |

MLPH04 (1004) Wire Wound Type Power Inductor

| R47 | 0.47 | ± 20% | 1MHz, 1V | 29 | 6.00 | 4.40 |

| 1R0 | 1.0 | ± 20% | 1MHz, 1V | 52 | 4.00 | 3.10 |

| 2R2 | 2.2 | ± 20% | 1MHz, 1V | 110 | 3.00 | 2.10 |

MLPH08 (1008) Wire Wound Type Power Inductor

| Codes | Inductance (uH) | Tolerance | Test Condition | DCR (mΩ) max. | Isat (A) max. | Irms (A) max. |

|---|---|---|---|---|---|---|

| R47 | 0.47 | ± 20% | 1MHz, 1V | 22 | 6.20 | 4.90 |

| 1R0 | 1.0 | ± 20% | 1MHz, 1V | 44 | 4.30 | 3.30 |

| 2R2 | 2.2 | ± 20% | 1MHz, 1V | 89 | 3.20 | 2.20 |

Operating Temperature range: -40°C to +125°C

Electrical Performance Test

| Item | Requirement | Test Method |

|---|---|---|

| Inductance | Refer to standard electrical characteristic spec. | HP4285A |

| DC Resistance RDC | micro-ohm meter. | |

| Isat | DC current will cause a 30% inductance reduction form initial value. | |

| Irms | DC current will cause coil temp. rising to 40℃ whichever is smaller. |

Mechanical Performance Test

| Item | Requirement | Test Method |

|---|---|---|

| Resistance to Soldering Heat | Appearance: No damage More than 95% of the terminal. Electrode should be covered with solder. Inductance: within ± 20% of initial value | Flux: Rosin Solder Temperature: 260 ± 5°C Immersion Time: 10 ± 1 sec. |

| Adhesive Test | No mechanical damage Soldering the products on PCB after the pulling test force>5N | Reflow temperature: 245°C it shall be soldered on the substrate applying direction parallel to the substrate Apply force(F): 5 N Test time: 10 sec |

| Temperature Cycle | No mechanical damage Inductance: within ± 20% of initial value | Temperature: -50 ~ 125°C for 30 minutes each Cycle: 500cycles Measurement: at ambient temperature 24 hours after test completion |

| Dry Heat Test | Temperature: 85 ± 2°C Testing time: 500 hrs Applied current: full rated current Measurement: at ambient temperature 24 hours after test completion | |

| Humidity Test | Temperature: 60 ± 2°C, Humidity: 90 ~ 95% RH Testing time: 500 hrs Applied current: full rated current Measurement: at ambient temperature 24 hours after test completion |

☑Storage Temperature: 5~40°C ; Humidity:<65%RH

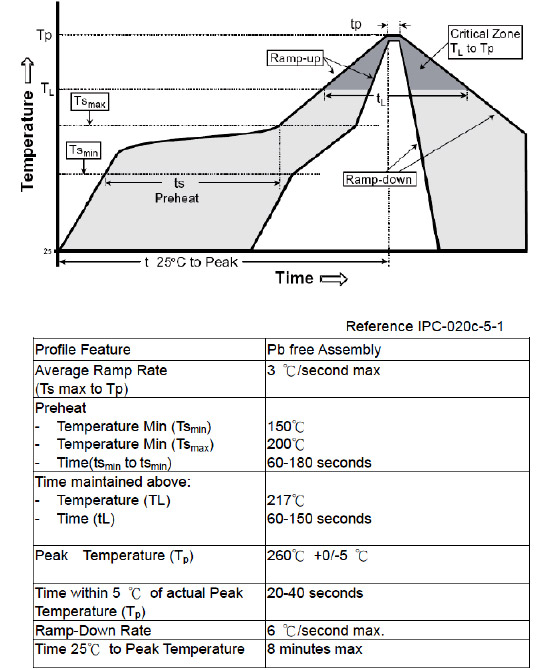

Recommendable Reflow Soldering

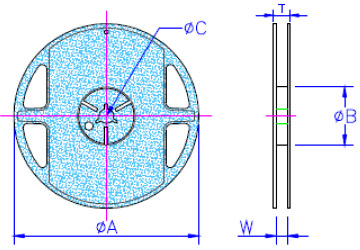

Reel Specifications (Unit: mm)

| Type | A | B | C | W | T | Quantity (EA) |  |

|---|---|---|---|---|---|---|---|

| MLP03 | 178 ± 1 | 60.0 + 0.5 | 13.0 ± 0.2 | 9.00 ± 0.5 | 12.0 ± 0.15 | 3,000 | |

| MLP05 | 178 ± 1 | 60.0 + 0.5 | 13.0 ± 0.2 | 9.00 ± 0.5 | 12.0 ± 0.15 | 3,000 | |

| MLP(H)06 | 178 ± 1 | 60.0 + 0.5 | 13.0 ± 0.2 | 9.00 ± 0.5 | 12.0 ± 0.15 | 3,000 | |

| MLP(H)04 | 178 ± 1 | 60.0 + 0.5 | 13.0 ± 0.2 | 9.00 ± 0.5 | 12.0 ± 0.15 | 3,000 | |

| MLP(H)08 | 178 ± 1 | 60.0 + 0.5 | 13.0 ± 0.2 | 9.00 ± 0.5 | 12.0 ± 0.15 | 3,000 | |

| MLP10 | 178 ± 1 | 60.0 + 0.5 | 13.0 ± 0.2 | 9.00 ± 0.5 | 12.0 ± 0.15 | 3,000 |

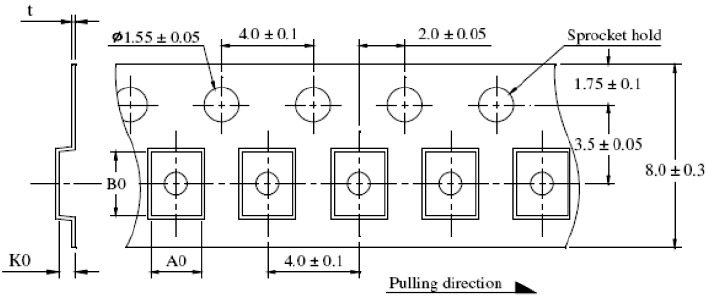

Tape Specifications (Unit: mm)

| Type | A0 | B0 | K0 | t |  |

|---|---|---|---|---|---|

| MLP03 | 1.45 ± 0.10 | 2.20 ± 0.10 | 1.12 ± 0.10 | 0.22 ± 0.05 | |

| MLP05 | 1.45 ± 0.10 | 2.20 ± 0.10 | 1.12 ± 0.10 | 0.22 ± 0.05 | |

| MLP06 | 1.80 ± 0.10 | 2.20 ± 0.10 | 1.15 ± 0.10 | 0.22 ± 0.05 | |

| MLPH06 | 1.82 ± 0.05 | 2.23 ± 0.05 | 1.15 ± 0.05 | 0.22 ± 0.05 | |

| MLP04 | 2.50 ± 0.10 | 3.00 ± 0.10 | 1.60 ± 0.10 | 0.25 ± 0.05 | |

| MLPH04 | 2.25 ± 0.05 | 2.80 ± 0.10 | 1.35 ± 0.10 | 0.22 ± 0.05 | |

| MLP08 | 2.50 ± 0.10 | 3.00 ± 0.10 | 1.60 ± 0.10 | 0.25 ± 0.05 | |

| MLPH08 | 2.25 ± 0.05 | 2.80 ± 0.10 | 1.35 ± 0.10 | 0.22 ± 0.05 | |

| MLP10 | 2.80 ± 0.10 | 3.45 ± 0.10 | 1.34 ± 0.10 | 0.23 ± 0.05 |

Dünnschicht-Präzisionswiderstand 0,01%, TC2ppm, Drahtbondable, Antikorrosiv, MELF. Stromsensoren, Metall,...

Weiterlesen

Keramische Hochfrequenz-Chip-Induktoren, klein bis 01005. Dünnschicht-, Mehrschicht-, Drahtgewickelte-,...

Weiterlesen

Mehrschicht-Keramikkondensator bietet hohe Spannung, hohe Frequenz, geringes Rauschen, hohe Güte, niedrige...

Weiterlesen