AUTOMOTIVE APPLICATIONS

Thin film Precision resistor 0.01%, TC2ppm, wirebondale, Anti-Crossive, MELF. Current sensing, Metal...

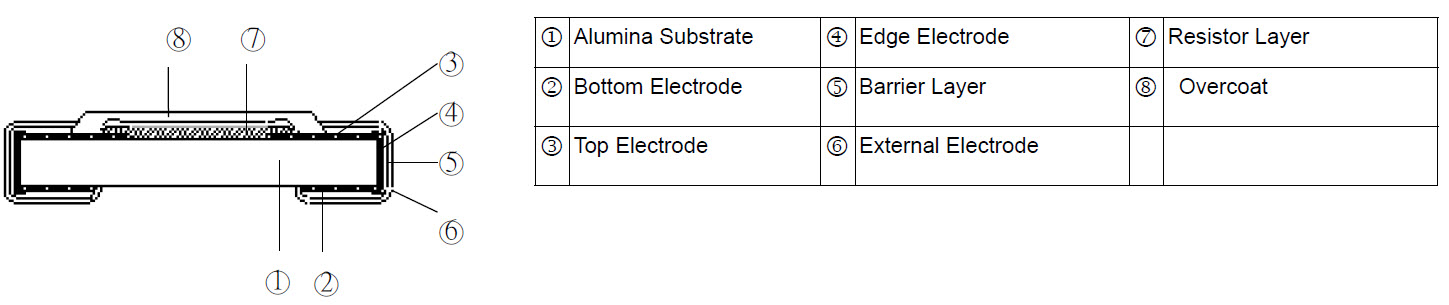

Read MoreThin film high precision resistor array, very accurate resistor network for tight tolerance, Low TCR with high tech thin film technology. Small size of resistor array.

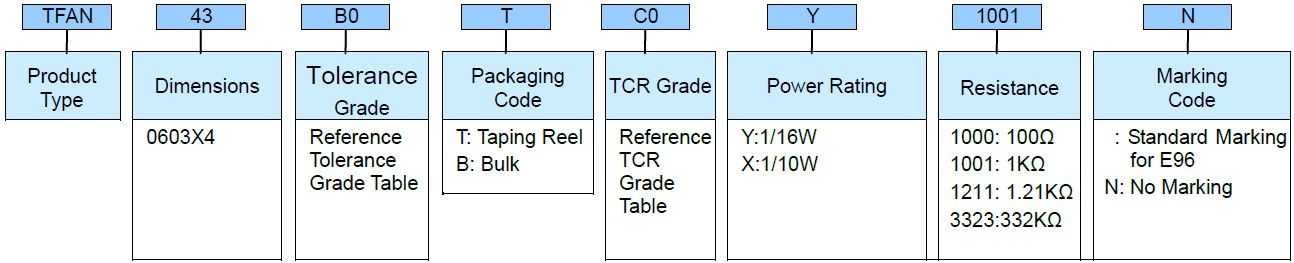

| Tolerance Grade | TCR Grade | ||||||

|---|---|---|---|---|---|---|---|

| Code | Absolute Tolerance | Tolerance Matching | Resistance Value | Code | Absolute TCR | TCR Tracking | Resistance Value |

| A0 | ±0.05% | N/A | 24.9~332K | S0 | ±5ppm | N/A | 24.9~60K |

| B0 | ±0.1% | N/A | 24.9~332K | S5 | ±5ppm | 5ppm | 24.9~60K |

| B3 | ±0.1% | 0.1% | 24.9~332K | B0 | ±10ppm | N/A | 24.9~332K |

| C0 | ±0.25% | N/A | 24.9~332K | B4 | ±10ppm | 10ppm | 24.9~332K |

| C2 | ±0.25% | 0.25% | 24.9~332K | B5 | ±10ppm | 5ppm | 24.9~60K |

| C3 | ±0.25% | 0.1% | 24.9~332K | N0 | ±15ppm | N/A | 24.9~332K |

| D0 | ±0.5% | N/A | 24.9~332K | N3 | ±15ppm | 15ppm | 24.9~332K |

| D1 | ±0.5% | 0.5% | 24.9~332K | N4 | ±15ppm | 10ppm | 24.9~332K |

| D2 | ±0.5% | 0.25% | 24.9~332K | N5 | ±15ppm | 5ppm | 24.9~60K |

| F0 | ±1% | N/A | 24.9~332K | C0 | ±25ppm | N/A | 24.9~332K |

| F1 | ±1% | 0.5% | 24.9~332K | C2 | ±25ppm | 25ppm | 24.9~332K |

| F2 | ±1% | 0.25% | 24.9~332K | C3 | ±25ppm | 15ppm | 24.9~332K |

| C4 | ±25ppm | 10ppm | 24.9~332K | ||||

| D0 | ±50ppm | N/A | 24.9~332K | ||||

| D1 | ±50ppm | 50ppm | 24.9~332K | ||||

| D2 | ±50ppm | 25ppm | 24.9~332K | ||||

| TYPE | Power Rating at 70°C | Operating Temp. Range | Max. Operating Voltage | Max. Overload Voltage | Resistance Range | TCR (PPM/°C) | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| ±0.05% | ±0.1% | ±0.25% | ±0.5% | ±1% | ||||||

| TFAN43 | 1/16W | -55 ~ +155°C | 50V | 100V | 24.9Ω~332KΩ | ±10 ±15 ±25 ±50 | ||||

| 1/10W 1/8W | -55 ~ +155°C | 75V | 150V | ±25 ±50 | ||||||

| 1/16W | -55 ~ +155°C | 50V | 100V | 24.9Ω~60KΩ | ±5 | |||||

| 1/10W | -55 ~ +155°C | 75V | 150V | |||||||

Thin film Precision resistor 0.01%, TC2ppm, wirebondale, Anti-Crossive, MELF. Current sensing, Metal...

Read More

Ceramic high frequency chip inductors, small size to 01005. Thin film, multilayer, wirewound , ferrite...

Read More

Multilayer Ceramic capacitor offers high Voltage, high frequency, low noise, High Q, Low TCR. NPO, X7R,...

Read More