APLICAÇÕES AUTOMOTIVAS

Resistor de precisão de filme fino 0,01%, TC2ppm, wirebondale, Anti-Corrosivo, MELF. Detecção de corrente,...

consulte Mais informaçãoIndutor de chip cerâmico enrolado em fio, alta frequência, indutor RF para alta SRF, excelente Q, estabilidade térmica superior. Indutância estável em circuitos de alta frequência. Design altamente estável para necessidades críticas.

WL Series0603 ±2% 300nHμH 2.8 Ω 220mA 47 0.99GHz

| Tamanho | Tolerância | Indutância | Condição de Teste | DCR (Ω) máx. | IDC (mA) | Q | SRF |

|---|---|---|---|---|---|---|---|

| 0603 | ±2% | 300nH | 100MHz | 2.8 | 220 | 47 | 0.99GHz |

WL03(H) Wire Wound Chip Inductors / High Current Type

| Inductance (nH) | Tolerance | L Freq. (MHz) | Quality Factor min. | SRF (GHz) min. | DCR (Ω) max. | IDC (mA) max. |

|---|---|---|---|---|---|---|

| 1.6 | ± 5, ± 10% | 250 | 24 | 12.50 | 0.030 | 2400 |

| 3.6 | ± 5, ± 10% | 250 | 24 | 5.90 | 0.048 | 2300 |

| 3.9 | ± 5, ± 10% | 250 | 25 | 5.90 | 0.054 | 2200 |

| 6.8 | ± 5, ± 10% | 250 | 35 | 5.80 | 0.054 | 2100 |

| 7.5 | ± 5, ± 10% | 250 | 38 | 3.70 | 0.059 | 2100 |

| 8.2 | ± 5, ± 10% | 250 | 38 | 3.70 | 0.060 | 2000 |

| 10 | ± 2, ± 5, ± 10% | 250 | 38 | 3.70 | 0.071 | 2000 |

| 12 | ± 2, ± 5, ± 10% | 250 | 38 | 3.00 | 0.075 | 2000 |

| 15 | ± 2, ± 5, ± 10% | 250 | 38 | 2.80 | 0.080 | 1900 |

| 18 | ± 2, ± 5, ± 10% | 250 | 40 | 2.80 | 0.099 | 1900 |

| 22 | ± 2, ± 5, ± 10% | 250 | 42 | 2.40 | 0.099 | 1800 |

| 24 | ± 2, ± 5, ± 10% | 250 | 42 | 2.40 | 0.105 | 1800 |

WL02(H) Wire Wound Chip Inductors / High Q Type

| Inductance (nH) | Tolerance | L Freq. (MHz) | Quality Factor | SRF (GHz) min. | DCR (Ω) max. | IDC (mA) max. | |

|---|---|---|---|---|---|---|---|

| 900MHz | 1.7GHz | ||||||

| 1.0 | ± 0.2nH, ± 0.5nH, ± 5%, ± 10% |

250 | 46 | 75 | 16.0 | 0.030 | 2300 |

| 2.0 | ± 0.2nH, ± 0.5nH, ± 5%, ± 10% |

250 | 58 | 85 | 15.2 | 0.038 | 2100 |

| 2.2 | ± 0.2nH, ± 0.5nH, ± 5%, ± 10% |

250 | 60 | 86 | 15.1 | 0.038 | 2100 |

| 2.4 | ± 0.2nH, ± 0.5nH, ± 5%, ± 10% |

250 | 60 | 83 | 14.0 | 0.042 | 2000 |

| 2.7 | ± 0.2nH, ± 0.5nH, ± 5%, ± 10% |

250 | 62 | 85 | 13.0 | 0.075 | 1500 |

| 3.3 | ± 0.2nH, ± 0.5nH, ± 5%, ± 10% |

250 | 66 | 95 | 12.8 | 0.045 | 1700 |

| 3.6 | ± 0.2nH, ± 0.5nH, ± 5%, ± 10% |

250 | 65 | 94 | 11.7 | 0.045 | 1700 |

| 3.9 | ± 0.2nH, ± 0.5nH, ± 5%, ± 10% |

250 | 64 | 98 | 9.50 | 0.045 | 1700 |

| 4.3 | ± 0.5nH, ± 5%, ± 10% | 250 | 63 | 90 | 7.15 | 0.050 | 1600 |

| 4.7 | ± 0.5nH, ± 5%, ± 10% | 250 | 58 | 83 | 6.85 | 0.070 | 1500 |

| 5.1 | ± 2%, ± 5%, ± 10% | 250 | 54 | 76 | 6.80 | 0.115 | 1200 |

| 5.6 | ± 2%, ± 5%, ± 10% | 250 | 73 | 105 | 6.50 | 0.050 | 1600 |

| 6.2 | ± 2%, ± 5%, ± 10% | 250 | 73 | 100 | 5.80 | 0.055 | 1600 |

| 6.8 | ± 2%, ± 5%, ± 10% | 250 | 68 | 94 | 5.80 | 0.065 | 1500 |

| 7.5 | ± 2%, ± 5%, ± 10% | 250 | 60 | 82 | 5.40 | 0.090 | 1400 |

| 8.2 | ± 2%, ± 5%, ± 10% | 250 | 68 | 95 | 5.40 | 0.065 | 1500 |

| 8.7 | ± 2%, ± 5%, ± 10% | 250 | 68 | 95 | 5.00 | 0.065 | 1500 |

| 9.0 | ± 2%, ± 5%, ± 10% | 250 | 67 | 92 | 5.00 | 0.080 | 1400 |

| 9.5 | ± 2%, ± 5%, ± 10% | 250 | 64 | 90 | 4.70 | 0.090 | 1400 |

| 10 | ± 2%, ± 5%, ± 10% | 250 | 62 | 90 | 4.70 | 0.100 | 1300 |

| 11 | ± 2%, ± 5%, ± 10% | 250 | 68 | 98 | 4.70 | 0.065 | 1400 |

| 12 | ± 2%, ± 5%, ± 10% | 250 | 66 | 100 | 4.40 | 0.100 | 1200 |

| 13 | ± 2%, ± 5%, ± 10% | 250 | 62 | 82 | 4.20 | 0.150 | 870 |

| 15 | ± 2%, ± 5%, ± 10% | 250 | 62 | 85 | 3.90 | 0.110 | 1100 |

| 16 | ± 2%, ± 5%, ± 10% | 250 | 57 | 77 | 3.70 | 0.140 | 850 |

| 18 | ± 2%, ± 5%, ± 10% | 250 | 58 | 74 | 3.55 | 0.120 | 900 |

| 19 | ± 2%, ± 5%, ± 10% | 250 | 61 | 88 | 3.50 | 0.145 | 850 |

| 20 | ± 2%, ± 5%, ± 10% | 250 | 58 | 76 | 3.50 | 0.185 | 780 |

| 21 | ± 2%, ± 5%, ± 10% | 250 | 48 | 62 | 1.70 | 0.460 | 450 |

| 22 | ± 2%, ± 5%, ± 10% | 250 | 60 | 74 | 3.30 | 0.160 | 800 |

| 23 | ± 2%, ± 5%, ± 10% | 250 | 60 | 77 | 3.30 | 0.160 | 800 |

| 24 | ± 2%, ± 5%, ± 10% | 250 | 55 | 71 | 3.15 | 0.200 | 700 |

| 25 | ± 2%, ± 5%, ± 10% | 250 | 57 | 73 | 3.15 | 0.250 | 600 |

| 26 | ± 2%, ± 5%, ± 10% | 250 | 56 | 74 | 3.15 | 0.285 | 450 |

| 27 | ± 2%, ± 5%, ± 10% | 250 | 62 | 86 | 3.20 | 0.320 | 450 |

| 30 | ± 2%, ± 5%, ± 10% | 250 | 61 | 87 | 2.90 | 0.330 | 450 |

| 33 | ± 2%, ± 5%, ± 10% | 250 | 61 | 80 | 2.80 | 0.330 | 490 |

| 36 | ± 2%, ± 5%, ± 10% | 250 | 59 | 76 | 2.80 | 0.380 | 480 |

| 37 | ± 2%, ± 5%, ± 10% | 250 | 57 | 72 | 2.70 | 0.460 | 470 |

| 39 | ± 2%, ± 5%, ± 10% | 250 | 56 | 84 | 2.60 | 0.430 | 450 |

| 40 | ± 2%, ± 5%, ± 10% | 250 | 56 | 75 | 2.60 | 0.430 | 450 |

| 43 | ± 2%, ± 5%, ± 10% | 250 | 52 | 68 | 2.50 | 0.520 | 450 |

| 47 | ± 2%, ± 5%, ± 10% | 250 | 48 | 62 | 2.40 | 0.580 | 420 |

| 51 | ± 2%, ± 5%, ± 10% | 250 | 52 | 59 | 2.30 | 0.700 | 360 |

WL03(Q) Wire Wound Chip Inductors / High Q Type

| Inductance (nH) | Tolerance | L Freq. (MHz) | Q Typ at 250(MHz) | SRF Typ (GHz) | DCR (Ω) max. | IDC (mA) max. | 900MHz | 1.7GHz | ||

|---|---|---|---|---|---|---|---|---|---|---|

| L Typ | Q Typ | L Typ | Q Typ | |||||||

| 1.8 | ± 5, ± 10% | 250 | 23 | 16.0 | 0.033 | 2100 | 1.77 | 40 | 1.77 | 65 |

| 2.2 | ± 5, ± 10% | 250 | 13 | 15.0 | 0.180 | 900 | 2.14 | 25 | 2.12 | 35 |

| 3.0 | ± 5, ± 10% | 250 | 35 | 9.50 | 0.024 | 1000 | 2.96 | 65 | 2.97 | 85 |

| 3.3 | ± 5, ± 10% | 250 | 32 | 9.60 | 0.024 | 1900 | 3.28 | 67 | 3.32 | 104 |

| 3.6 | ± 2, ± 5, ± 10% | 250 | 40 | 9.70 | 0.031 | 1900 | 3.59 | 70 | 3.62 | 116 |

| 3.9 | ± 2, ± 5, ± 10% | 250 | 35 | 7.50 | 0.039 | 1600 | 3.88 | 68 | 3.95 | 108 |

| 4.3 | ± 2, ± 5, ± 10% | 250 | 30 | 7.50 | 0.080 | 1300 | 4.29 | 58 | 4.31 | 91 |

| 4.7 | ± 2, ± 5, ± 10% | 250 | 26 | 7.90 | 0.100 | 1100 | 4.65 | 48 | 4.71 | 75 |

| 5.1 | ± 2, ± 5, ± 10% | 250 | 40 | 8.90 | 0.036 | 1700 | 5.08 | 84 | 5.12 | 140 |

| 5.6 | ± 2, ± 5, ± 10% | 250 | 48 | 6.60 | 0.036 | 1700 | 5.6 | 87 | 5.73 | 456 |

| 6.0 | ± 2, ± 5, ± 10% | 250 | 49 | 6.00 | 0.036 | 1700 | 5.92 | 94 | 6.12 | 154 |

| 6.8 | ± 2, ± 5, ± 10% | 250 | 42 | 5.80 | 0.042 | 1400 | 6.83 | 88 | 7.05 | 143 |

| 7.2 | ± 2, ± 5, ± 10% | 250 | 48 | 5.40 | 0.052 | 1400 | 7.25 | 96 | 7.38 | 139 |

| 7.5 | ± 2, ± 5, ± 10% | 250 | 41 | 5.30 | 0.080 | 1300 | 7.55 | 81 | 7.85 | 12 |

| 8.2 | ± 2, ± 5, ± 10% | 250 | 46 | 5.90 | 0.054 | 1400 | 8.21 | 96 | 8.39 | 148 |

| 8.7 | ± 2, ± 5, ± 10% | 250 | 46 | 5.50 | 0.054 | 1400 | 8.73 | 97 | 9.00 | 149 |

| 9.1 | ± 2, ± 5, ± 10% | 250 | 40 | 5.10 | 0.037 | 1400 | 9.18 | 76 | 9.64 | 109 |

| 9.5 | ± 2, ± 5, ± 10% | 250 | 49 | 4.90 | 0.053 | 1400 | 9.56 | 98 | 9.99 | 149 |

| 10 | ± 2, ± 5, ± 10% | 250 | 49 | 4.30 | 0.048 | 1400 | 10.16 | 90 | 10.64 | 142 |

| 11 | ± 2, ± 5, ± 10% | 250 | 41 | 4.10 | 0.058 | 1400 | 11.06 | 78 | 11.82 | 108 |

| 12 | ± 2, ± 5, ± 10% | 250 | 37 | 4.10 | 0.088 | 1100 | 12.26 | 69 | 13.2 | 91 |

| 15 | ± 2, ± 5, ± 10% | 250 | 48 | 3.60 | 0.078 | 1200 | 15.41 | 83 | 17.2 | 124 |

| 16 | ± 2, ± 5, ± 10% | 250 | 45 | 3.50 | 0.085 | 1100 | 16.37 | 77 | 18.7 | 116 |

| 18 | ± 2, ± 5, ± 10% | 250 | 41 | 3.30 | 0.066 | 1200 | 18.56 | 76 | 20.9 | 100 |

| 22 | ± 2, ± 5, ± 10% | 250 | 44 | 3.15 | 0.140 | 850 | 22.7 | 77 | 25.9 | 88 |

| 23 | ± 2, ± 5, ± 10% | 250 | 40 | 3.00 | 0.183 | 850 | 24 | 69 | 29.53 | 80 |

| 24 | ± 2, ± 5, ± 10% | 250 | 42 | 2.95 | 0.074 | 1100 | 24.9 | 77 | 28.9 | 91 |

| 27 | ± 2, ± 5, ± 10% | 250 | 44 | 2.80 | 0.150 | 780 | 28.4 | 74 | 34.0 | 84 |

| 30 | ± 2, ± 5, ± 10% | 250 | 49 | 2.80 | 0.130 | 920 | 31.5 | 82 | 37.9 | 82 |

| 33 | ± 2, ± 5, ± 10% | 250 | 45 | 2.70 | 0.170 | 680 | 34.9 | 76 | 42.9 | 80 |

| 36 | ± 2, ± 5, ± 10% | 250 | 44 | 2.50 | 0.225 | 720 | 38.5 | 69 | 50.0 | 64 |

| 39 | ± 2, ± 5, ± 10% | 250 | 48 | 2.45 | 0.19 | 680 | 41.5 | 78 | 51.9 | 74 |

| 43 | ± 2, ± 5, ± 10% | 250 | 45 | 2.45 | 0.17 | 810 | 45.7 | 83 | 58.1 | 76 |

| 47 | ± 2, ± 5, ± 10% | 200 | 47 | 2.30 | 0.24 | 680 | 50.6 | 77 | 66.9 | 72 |

| 51 | ± 2, ± 5, ± 10% | 200 | 49 | 2.30 | 0.28 | 660 | 54.6 | 73 | 71.3 | 62 |

| 56 | ± 2, ± 5, ± 10% | 200 | 50 | 2.20 | 0.30 | 610 | 60.3 | 74 | 79.9 | 56 |

| 68 | ± 2, ± 5, ± 10% | 200 | 46 | 2.00 | 0.33 | 600 | 75.5 | 73 | 113.3 | 49 |

| 72 | ± 2, ± 5, ± 10% | 150 | 46 | 1.90 | 0.42 | 550 | 80.8 | 69 | - | - |

| 75 | ± 2, ± 5, ± 10% | 150 | 46 | 1.90 | 0.52 | 500 | 84.6 | 71 | - | - |

| 82 | ± 2, ± 5, ± 10% | 150 | 45 | 1.80 | 0.46 | 510 | 94 | 62 | - | - |

| 91 | ± 2, ± 5, ± 10% | 150 | 45 | 1.65 | 0.58 | 440 | 103 | 64 | - | - |

| 100 | ± 2, ± 5, ± 10% | 150 | 49 | 1.70 | 0.54 | 470 | 114 | 69 | - | - |

| 110 | ± 2, ± 5, ± 10% | 150 | 47 | 1.60 | 0.58 | 440 | 126.2 | 63 | - | - |

| 120 | ± 2, ± 5, ± 10% | 150 | 47 | 1.55 | 0.72 | 420 | 142.4 | 61 | - | - |

| 150 | ± 2, ± 5, ± 10% | 150 | 47 | 1.35 | 0.82 | 390 | 188.8 | 57 | - | - |

| 180 | ± 2, ± 5, ± 10% | 100 | 48 | 1.30 | 1.50 | 310 | 232.2 | 50 | - | - |

| 200 | ± 2, ± 5, ± 10% | 100 | 47 | 1.25 | 2.00 | 280 | 265 | 47 | - | - |

| 210 | ± 2, ± 5, ± 10% | 100 | 48 | 1.20 | 2.00 | 280 | 288 | 45 | - | - |

| 220 | ± 2, ± 5, ± 10% | 100 | 47 | 1.10 | 2.00 | 280 | 315 | 41 | - | - |

| 250 | ± 2, ± 5, ± 10% | 100 | 45 | 1.05 | 3.00 | 240 | - | - | - | - |

| 270 | ± 2, ± 5, ± 10% | 100 | 46 | 1.05 | 2.25 | 260 | - | - | - | - |

| 300 | ± 2, ± 5, ± 10% | 100 | 47 | 0.99 | 2.80 | 220 | - | - | - | - |

| 330 | ± 2, ± 5, ± 10% | 100 | 46 | 0.93 | 3.60 | 180 | - | - | - | - |

| 360 | ± 2, ± 5, ± 10% | 100 | 47 | 0.93 | 4.00 | 170 | - | - | - | - |

| 390 | ± 2, ± 5, ± 10% | 100 | 47 | 0.88 | 4.00 | 170 | - | - | - | - |

WL05(H) Wire Wound Chip Inductors / High Q Type

| Inductance (nH) | Tolerance | L Freq. (MHz) | Quality Factor min. | SRF (GHz) min. | DCR (Ω) max. | IDC (mA) max. |

|---|---|---|---|---|---|---|

| 2.5 | ± 5, ± 10% | 250 | 80 @ 1500MHz | 6.00 | 0.020 | 1600 |

| 5.6 | ± 5, ± 10% | 250 | 98 @ 1500MHz | 6.00 | 0.035 | 1600 |

| 6.2 | ± 5, ± 10% | 250 | 88 @ 1000MHz | 4.75 | 0.035 | 1600 |

| 6.8 | ± 5, ± 10% | 250 | 80 @ 1000MHz | 4.40 | 0.035 | 1600 |

| 8.2 | ± 5, ± 10% | 250 | 75 @ 1000MHz | 3.00 | 0.075 | 1000 |

| 10 | ± 5, ± 10% | 250 | 80 @ 1000MHz | 3.00 | 0.060 | 1600 |

| 12 | ± 5, ± 10% | 250 | 80 @ 1000MHz | 3.00 | 0.045 | 1600 |

| 15 | ± 2, ± 5, ± 10% | 250 | 80 @ 1000MHz | 2.80 | 0.100 | 1200 |

| 16 | ± 2, ± 5, ± 10% | 250 | 72 @ 500MHz | 2.95 | 0.060 | 1500 |

| 18 | ± 2, ± 5, ± 10% | 250 | 75 @ 500MHz | 2.55 | 0.060 | 1400 |

| 20 | ± 2, ± 5, ± 10% | 250 | 70 @ 500MHz | 2.05 | 0.055 | 1400 |

| 22 | ± 2, ± 5, ± 10% | 250 | 80 @ 500MHz | 2.00 | 0.100 | 1200 |

| 27 | ± 2, ± 5, ± 10% | 250 | 75 @ 500MHz | 2.00 | 0.070 | 1300 |

| 30 | ± 2, ± 5, ± 10% | 250 | 65 @ 500MHz | 1.95 | 0.095 | 1200 |

| 39 | ± 2, ± 5, ± 10% | 250 | 65 @ 500MHz | 1.60 | 0.110 | 1100 |

| 48 | ± 2, ± 5, ± 10% | 200 | 65 @ 500MHz | 1.40 | 0.095 | 1200 |

| 51 | ± 2, ± 5, ± 10% | 200 | 65 @ 500MHz | 1.40 | 0.120 | 1000 |

WL08(H) Wire Wound Chip Inductors / High Q Type

| Inductance (nH) | Tolerance | L Freq. (MHz) | Quality Factor min. | SRF (GHz) min. | DCR (Ω) max. | IDC (mA) max. |

|---|---|---|---|---|---|---|

| 3.0 | ± 5, ± 10% | 50 | 70 @ 1500MHz | 6.00 | 0.04 | 1600 |

| 3.9 | ± 5, ± 10% | 50 | 75 @ 1500MHz | 6.00 | 0.05 | 1600 |

| 4.1 | ± 5, ± 10% | 50 | 75 @ 1500MHz | 6.00 | 0.05 | 1600 |

| 7.8 | ± 5, ± 10% | 50 | 75 @ 500MHz | 3.80 | 0.05 | 1600 |

| 10 | ± 2, ± 5, ± 10% | 50 | 60 @ 500MHz | 3.60 | 0.06 | 1600 |

| 12 | ± 2, ± 5, ± 10% | 50 | 70 @ 500MHz | 2.80 | 0.06 | 1500 |

| 18 | ± 2, ± 5, ± 10% | 50 | 62 @ 350MHz | 2.70 | 0.07 | 1400 |

| 22 | ± 2, ± 5, ± 10% | 50 | 62 @ 350MHz | 2.05 | 0.07 | 1400 |

| 33 | ± 2, ± 5, ± 10% | 50 | 75 @ 350MHz | 1.70 | 0.09 | 1300 |

| 39 | ± 2, ± 5, ± 10% | 50 | 75 @ 350MHz | 1.30 | 0.09 | 1300 |

| 47 | ± 2, ± 5, ± 10% | 50 | 75 @ 350MHz | 1.45 | 0.12 | 1200 |

| 56 | ± 2, ± 5, ± 10% | 50 | 75 @ 350MHz | 1.23 | 0.12 | 1200 |

| 68 | ± 2, ± 5, ± 10% | 50 | 80 @ 350MHz | 1.15 | 0.13 | 1100 |

| 82 | ± 2, ± 5, ± 10% | 50 | 80 @ 350MHz | 1.06 | 0.16 | 1100 |

| 100 | ± 2, ± 5, ± 10% | 50 | 50 @ 350MHz | 0.82 | 0.16 | 1000 |

| 120 | ± 2, ± 5, ± 10% | 100 | 50 @ 100MHz | 0.82 | 0.16 | 1000 |

☑ Parts (3.0nH, 7.8nH) are wound on a low profile bobbin. (Max 2.41 x 2.01 x 1.09)

Electrical Performance Test

| Item | Requirement | Test Method |

|---|---|---|

| Inductance | Refer to standard electrical characteristic spec. | HP4286/E4982A |

| Q | HP4286/E4982A | |

| SRF | HP4287/E4982A | |

| DC Resistance RDC | Micro-Ohm meter (Gom-801G)/E4982A | |

| Rated Current IDC | Applied the current to coils, the temperature of coil increases ΔT15°C (Ta = 25°C). | |

| Over Load | Inductors shall have no evidence of electrical and mechanical damage | Applied 2 times of rated allowed DC current to inductor for a period of 5 minutes |

| Withstanding Voltage | Inductors shall be no evidence of electrical and mechanical damage. | AC voltage of 500 VAC applied between inductors terminal and case for 1 min. |

| Insulation Resistance | 1000M ohm min. | 100 VDC applied between inductor terminal and case |

Mechanical Performance Test

| Item | Requirement | Test Method |

|---|---|---|

| Vibration | Appearance: No damage L change: within ± 5% Q change: within ± 10% |

Test device shall be soldered on the substrate Oscillation Frequency: 10 to 55 to 10Hz for 1 min. Amplitude: 1.5 mm Time: 2 hrs for each axis (X, Y & Z), total 6 hrs |

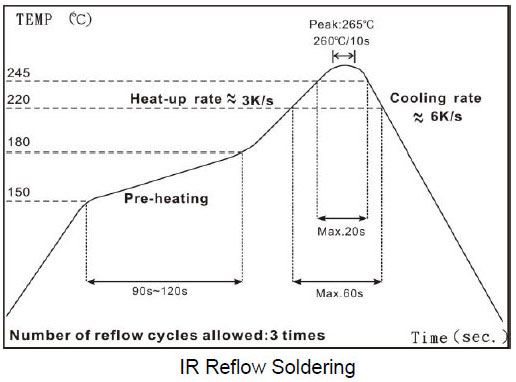

| Resistance to Soldering Heat | Solder Temperature: 260± 5°C Immersion Time: 10± 2 seconds |

|

| Component Adhesion (Push Test) |

1 lbs. For 0402 2 lbs. For 0603 3 lbs. For the rest |

The device should be soldered (260± 5°C for 10 seconds) to a tinned copper subs rate. A dynamiter force gauge should be applied to the side of the component. The device must with stand a minimum force of 2 or 4 pounds without a failure of adhesion on termination |

| Drop | No damage | Dropping chip by each side and each corner. Drop 10 times in total Drop height: 100 cm Drop weight: 125 g |

| Solderability | 90% covered with solder | Inductor shall be dipped in a melted solder bath at 245± 5°C for 3 seconds |

| Resistance to Solvent | No damage on appearance and marking |

MIL-STD-202, Method 215 |

Climatic Test

| Item | Requirement | Item | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Temperature Characteristic | Appearance: No damage L change: within ± 10% Q change: within ± 20% |

-40°C ~ +125°C | ||||||||||||||

| Humidity | Temperature: 40± 2°C Relative Humidity: 90 ~ 95% Time: 96± 2 hrs Measured after exposure in the room condition for 2 hrs |

|||||||||||||||

| Low Temperature Storage | Temperature: -40± 2°C Time: 96± 2 hrs Inductors are tested after 1 hour at room temperature |

|||||||||||||||

| Thermal Shock | One cycle:

Total: 5 cycles |

|||||||||||||||

| High Temperature Storage | Temperature: 125± 2°C Time: 96± 2 hrs Measured after exposure in the room condition for 1hour |

|||||||||||||||

| High Temperature Load Life | There should be no evidence of short of open circuit. |

Temperature: 85± 2°C Time: 1000± 12 hrs Load: Allowed DC current |

||||||||||||||

| Damp Heat with Load | Temperature: 40± 2°C Relative Humidity: 90 ~ 95% Time: 1000± 12 hrs Load: Allowed DC current |

☑ Storage Temperature: 15 ~ 28°C; Humidity < 80%RH

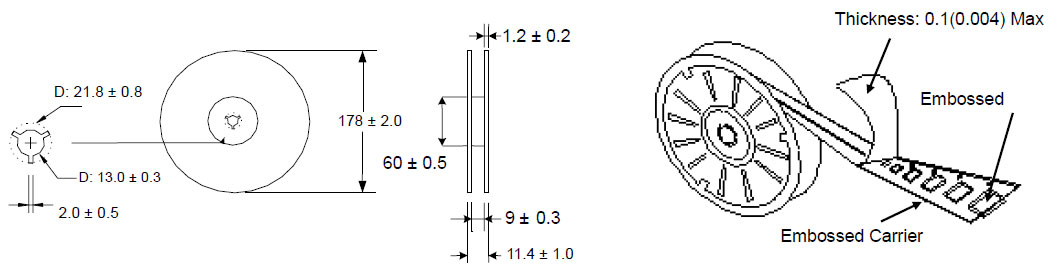

Reel Dimensions & Packaging Quantity (Unit : mm)

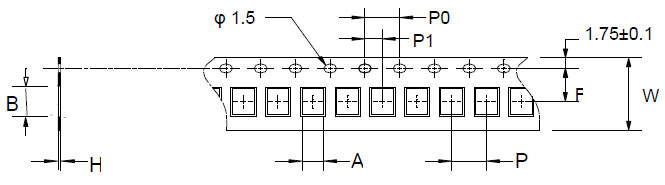

Paper Tape specification and Packaging Quantity (Unit : mm)

| Type | A | B | H | F | P | P0 | P1 | W | Reel (EA) |

|---|---|---|---|---|---|---|---|---|---|

| WL02 | 0.81 | 1.23 | 0.73 | 3.50 | 2.00 | 4.00 | 2.00 | 8.00 | 4,000 |

| WL03 | 1.35 | 1.95 | 0.95 | 3.50 | 4.00 | 4.00 | 2.00 | 8.00 | 4,000 |

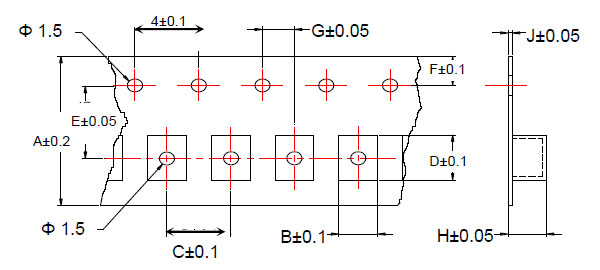

Embossed Plastic Tape specification and Packaging Quantity (Unit : mm)

| Type | A | B | C | D | E | F | G | H | J | Reel (EA) |

|---|---|---|---|---|---|---|---|---|---|---|

| WL05 | 8 | 1.85 | 4 | 2.30 | 3.5 | 1.75 | 2 | 1.45 | 0.23 | 2,000 |

| WL05 (H) | 8 | 1.85 | 4 | 2.30 | 3.5 | 1.75 | 2 | 1.45 | 0.23 | 2,000 |

| WL08 | 8 | 2.70 | 4 | 2.80 | 3.5 | 1.75 | 2 | 2.00 | 0.23 | 2,000 |

| WL08 (H) | 8 | 2.70 | 4 | 2.80 | 3.5 | 1.75 | 2 | 2.00 | 0.23 | 2,000 |

Resistor de precisão de filme fino 0,01%, TC2ppm, wirebondale, Anti-Corrosivo, MELF. Detecção de corrente,...

consulte Mais informação

Indutores de chip de alta frequência cerâmicos, de tamanho pequeno até 01005. Filme fino, multicamada,...

consulte Mais informação

O capacitor cerâmico multicamadas oferece alta voltagem, alta frequência, baixo ruído, alto Q, baixo...

consulte Mais informação