AUTOMOBIEL TOEPASSINGEN

Dunne film precisie weerstand 0,01%, TC2ppm, draadgebonden, anti-corrosief, MELF. Stroomdetectie, Metaal,...

Lees verderAlgemene dikke film stroommeetweerstand, standaard TC, lage kosten voor grote vraag naar energiebeheer.

RS Series0603 ±5% 500 1/8W Series110mΩ

| Grootte | Tolerantie | TCR (ppm /℃) | Vermogen | Weerstand (Ohm) |

|---|---|---|---|---|

| 0603 | ±5% | 500 | 1/8W | 110m |

| Item Type |

Power Rating at 70°C |

Operating Temp. Range |

Max. Operating Current |

Resistance Range (mΩ) | TCR (PPM/°C) |

|

|---|---|---|---|---|---|---|

| ±1% | ±5% | |||||

| RS-02 (0402) | 1/10W | -55 ~ +155°C | 1.40A | 50 - 91 100 - 976 |

±800 ±500 |

|

| RS-03 (0603) | 1/8W | -55 ~ +155°C | 2.50A | 20 - 47 50 - 91 100 - 976 |

±1200 ±800 ±500 |

|

| RS-05 (0805) | 1/4W | -55 ~ +155°C | 5.00A | 10 - 18 20 - 47 50 - 91 100 - 976 |

±1500 ±1200 ±800 ±500 |

|

| RS-06 (1206) | 1/2W | -55 ~ +155°C | 7.07A | |||

| RS-10 (1210) | 1/2W | -55 ~ +155°C | 7.07A | 10 - 18 20 - 91 100 - 976 |

±1500 ±800 ±500 |

|

| RS-0A (2010) | 1W | -55 ~ +155°C | 10.0A | |||

| RS-12 (2512) | 2W | -55 ~ +155°C | 14.1A | |||

Operating Voltage=√(P*R)

Overload Voltage=2.5*√(P*R)

Operating Current=√(P/R)

☑ Viking is capable of manufacturing the optional spec based on customer's requirement.

| Item | Requirement | Test Method | |

|---|---|---|---|

| ±1% | ±5% | ||

| Temperature Coefficient of Resistance (T.C.R.) |

As Spec. | JIS-C-5201-1 4.8 IEC-60115-1 4.8 -55°C~+125°C, 25°C is the reference temperature |

|

| Short Time Overload | ±(1.0%+0.05Ω) | ±(2.0%+0.05Ω) | JIS-C-5201-1 4.13 IEC-60115-1 4.13 RCWV*2.5 or Max. Overload Voltage whichever is lower for 5 seconds, 2 seconds for High Power Series |

| Insulation Resistance | ≥10G | JIS-C-5201-1 4.6 IEC-60115-1 4.6 Max. Overload Voltage for 1 minute |

|

| Endurance | ±(1.0%+0.10Ω) | ±(2.0%+0.10Ω) | JIS-C-5201-1 4.25 IEC-60115-1 4.25.1 70±2°C, RCWV for 1000 hrs with 1.5 hrs “ON” and 0.5 hr “OFF” |

| Damp Heat with Load | ±(1.0%+0.10Ω) | ±(2.0%+0.10Ω) | JIS-C-5201-1 4.24 IEC-60115-1 4.24 40±2°C, 90~95% R.H., RCWV for 1000 hrs with 1.5 hrs “ON” and 0.5 hr “OFF” |

| Dry Heat | ±(1.0%+0.05Ω) | ±(1.5%+0.10Ω) | JIS-C-5201-1 4.23 IEC-60115-1 4.23.2 at +155°C for 1000 hrs |

| Bending Strength | ±(1.0%+0.05Ω) | ±(1.0%+0.05Ω) | JIS-C-5201-1 4.33 IEC-60115-1 4.33 Bending once for 5 seconds 2010, 2512 sizes: 2mm Other sizes: 3mm |

| Solderability | 95% min. coverage | JIS-C-5201-1 4.17 IEC-60115-1 4.17 245±5°C for 3 seconds |

|

| Resistance to Soldering Heat | ±(0.5%+0.05Ω) | ±(1.0%+0.05Ω) | JIS-C-5201-1 4.18 IEC-60115-1 4.18 260±5°C for 10 seconds |

| Voltage Proof | No breakdown or flashover | JIS-C-5201-1 4.7 IEC-60115-1 4.7 1.42 times Max. Operating Voltage for 1 minute |

|

| Leaching | Individual leaching area ≦5% Total leaching area ≦ 10% |

JIS-C-5201-1 4.18 IEC-60068-2-58 8.2.1 260±5°C for 30 seconds |

|

| Rapid Change of Temperature | ±(0.5%+0.05Ω) | ±(1.0%+0.05Ω) | JIS-C-5201-1 4.19 IEC-60115-1 4.19 -55°C to +155°C, 5 cycles |

RCWV(Rated Continuous Working Voltage)=√(P*R) or Max. Operating Voltage whichever is lower.

☑ Storage Temperature: 15~28°C; Humidity < 80%RH

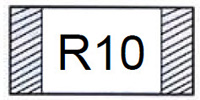

No Marking for 0402

1%, 5% for 0805/1206/1210/2010/2512: 4 digits marking

Example:

| Resistance | 47mΩ | 75mΩ | 15mΩ | 750mΩ | 820mΩ |

|---|---|---|---|---|---|

| Marking | R047 | R075 | R015 | R750 | R820 |

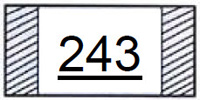

5% for 0603: 3 digits marking in E24

1% for 0603: 3 digits marking with under-line in E96 (non-including E24 series)

3 digits marking for E24 or R value suffix is zero in E96: R10=100mΩ; R28=280mΩ,

3 digits marking for E96: 243=243mΩ; 511=511mΩ

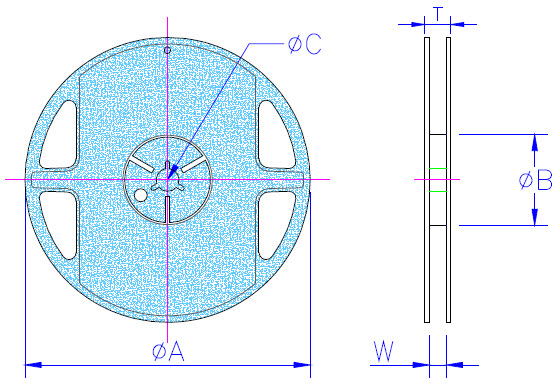

Packing Quantity & Reel Specifications

| Type | Packaging Quantity |

Tape Width |

Reel Diameter |

ΦA (mm) |

ΦB (mm) |

ΦC (mm) |

W (mm) |

T (mm) |

|

|

|---|---|---|---|---|---|---|---|---|---|---|

| RS-02 | Paper | 10K | 8mm | 7 inch | 178.5±1.5 | 60+1/-0 | 13.0±0.2 | 9.0±0.5 | 12.5±0.5 | |

| 20K | 8mm | 10 inch | 254±1.0 | 100±0.5 | 13.0±0.2 | 9.5±0.5 | 13.5±0.5 | |||

| 40K | 8mm | 13 inch | 330±1.0 | 100±0.5 | 13.0±0.2 | 9.5±0.5 | 13.5±0.5 | |||

| RS-03 RS-05 RS-06 RS-10 |

Paper | 5K | 8mm | 7 inch | 178.5±1.5 | 60+1/-0 | 13.0±0.2 | 9.0±0.5 | 12.5±0.5 | |

| 10K | 8mm | 10 inch | 254±1.0 | 100±0.5 | 13.0±0.2 | 9.5±0.5 | 13.5±0.5 | |||

| 20K | 8mm | 13 inch | 330±1.0 | 100±0.5 | 13.0±0.2 | 9.5±0.5 | 13.5±0.5 | |||

| RS-0A RS-12 |

Embossed | 4K | 12mm | 7 inch | 178.5±1.5 | 60+1/-0 | 13.0±0.5 | 13.0±0.5 | 15.5±0.5 | |

| 8K | 12mm | 10 inch | 250±1.0 | 62±0.5 | 13.0±0.5 | 12.5±0.5 | 16.5±0.5 | |||

Paper Tape Specifications

| Type | A (mm) |

B (mm) |

W (mm) |

E (mm) |

F (mm) |

P0 (mm) |

P1 (mm) |

P2 (mm) |

ΦD0 (mm) |

T (mm) |

|---|---|---|---|---|---|---|---|---|---|---|

| RS-02 | 0.65±0.10 | 1.15±0.10 | 8.0±0.20 | 1.75±0.10 | 3.50±0.05 | 4.00±0.10 | 2.00±0.05 | 2.00±0.05 | 1.50+0.1,-0 | 0.45±0.10 |

| RS-03 | 1.10±0.10 | 1.90±0.10 | 8.0±0.20 | 1.75±0.10 | 3.50±0.05 | 4.00±0.10 | 4.00±0.05 | 2.00±0.05 | 1.50+0.1,-0 | 0.70±0.10 |

| RS-05 | 1.60±0.10 | 2.40±0.20 | 8.0±0.20 | 1.75±0.10 | 3.50±0.05 | 4.00±0.10 | 4.00±0.05 | 2.00±0.05 | 1.50+0.1,-0 | 0.85±0.10 |

| RS-06 | 1.90±0.10 | 3.50±0.20 | 8.0±0.20 | 1.75±0.10 | 3.50±0.05 | 4.00±0.10 | 4.00±0.05 | 2.00±0.05 | 1.50+0.1,-0 | 0.85±0.10 |

| RS-10 | 2.90±0.10 | 3.50±0.20 | 8.0±0.20 | 1.75±0.10 | 3.50±0.05 | 4.00±0.10 | 4.00±0.05 | 2.00±0.05 | 1.50+0.1,-0 | 0.85±0.10 |

Embossed Plastic Tape Specifications

| Type | A (mm) |

B (mm) |

W (mm) |

E (mm) |

F (mm) |

P0 (mm) |

P1 (mm) |

P2 (mm) |

ΦD0 (mm) |

T (mm) |

|---|---|---|---|---|---|---|---|---|---|---|

| RS-0A | 2.8±0.10 | 5.5±0.10 | 12.0±0.30 | 1.75±0.10 | 5.5±0.05 | 4.00±0.10 | 4.00±0.10 | 2.00±0.05 | 1.50+0.1, -0 | 1.2+0 |

| RS-12 | 3.5±0.10 | 6.7±0.10 | 12.0±0.30 | 1.75±0.10 | 5.5±0.05 | 4.00±0.10 | 4.00±0.10 | 2.00±0.05 | 1.50+0.1, -0 | 1.2+0 |

Dunne film precisie weerstand 0,01%, TC2ppm, draadgebonden, anti-corrosief, MELF. Stroomdetectie, Metaal,...

Lees verder

Keramische hoogfrequente chip spoelen, klein formaat tot 01005. Dunne film, meerlaags, draadgewonden,...

Lees verder

Multilayer keramische condensator biedt hoge spanning, hoge frequentie, lage ruis, hoge Q, lage TCR....

Lees verder