AUTOMOBIEL TOEPASSINGEN

Dunne film precisie weerstand 0,01%, TC2ppm, draadgebonden, anti-corrosief, MELF. Stroomdetectie, Metaal,...

Lees verderHoogvermogen dunne film chipweerstand - ARP-serie

ARP Series1206 ±1% 50 1W Series270Ω 5K/Reel

| Grootte | Tolerantie | TCR (ppm /℃) | Vermogen | Weerstand (Ohm) | Verpakking |

|---|---|---|---|---|---|

| 1206 | ±1% | 50 | 1W | 270 | 5K/Reel |

| Item | Requirement | Test Method | |

|---|---|---|---|

| Resistance<47Ω | Resistance≧47Ω | ||

| Temperature Coefficient of Resistance (T.C.R.) | As Spec. | JIS-C-5201-1 4.8 IEC-60115-1 4.8 +25/-55/+25/+125/+25°C |

|

| Short Time Overload(Power Operation Mode) | ΔR±0.4% | ΔR±0.2% | JIS-C-5201-1 4.13 IEC-60115-1 4.13 RCWV x 2.5 or Max. overload voltage whichever is lower for 5 seconds |

| Insulation Resistance | >1000 MΩ | JIS-C-5201-1 4.6 IEC-60115-1 4.6 Apply 100VDC for 1 minute |

|

| Endurance | ΔR±0.5% | ΔR±0.25% | JIS-C-5201-1 4.13 IEC-60115-1 4.13 70±2°C ,RCWV for 1000 hrs with 1.5hrs “ON” and 0.5 hr “OFF” |

| High Temperature Exposure | ΔR±0.25% | ΔR±0.1% | MIL-STD-202 Method 108 at +155°C for 1000 hrs |

| Biased Humidity | ΔR±0.25% | ΔR±0.1% | MIL-STD-202 Method 103 1000 hrs 85°C/85%RH 10% of operating power. |

| Temperature Cycling | ΔR±0.25% | ΔR±0.1% | JESD22 Method JA-104 -55°C to +125°C, 1000 cycles |

| Bending Strength (Board Flex) | ΔR±0.1% | IEC-60115-1 4.33 JIS-C-5201-1 6.1.4 Bending once for 60 seconds. Bending displacement 0805 size: 3mm |

|

| Solderability | 95% min. coverage | JIS-C-5201-1 4.17 IEC-60115-1 4.17 245± 5°C for 3 seconds |

|

| Resistance to Soldering Heat | ΔR±0.25% | ΔR±0.1% | JIS-C-5201-1 4.18 IEC-60115-1 4.18 260± 5°C for 10 seconds |

| Terminal strength | No broken | AEC-Q200-006 Force of 1.8kg for 60 seconds. |

|

| Mechanical Shock | ΔR±0.1% | MIL-STD-202 Method 213 Wave Form: Tolerance for half sine shock pulse. Peak value is 100g's. Normal duration (D) is 6. |

|

| Vibration | ΔR±0.1% | MIL-STD-202 Method 204 5 g's for 20 min., 12 cycles each of 3 orientations, 10-2000 Hz |

|

| ESD | Δ R± 0.5% | AEC-Q200-002 Human body model 1206: 1KV |

|

| Resistance to solvents | Marking Unsmeared | MIL-STD-202 Method 215 Add Aqueous wash chemical - OKEM Clean or equivalent. Do not use banned solvents. |

|

| Flammability | No ignition of the tissue paper or scorching or the pinewood board | UL-94 V-0 or V-1 are acceptable. Electrical test not required. |

|

| Sulfur Test | ΔR±0.1% | ASTM-B-809-95 105±2°C no power rating for 750 hrs |

|

RCWV (Rated continuous working voltage)= √(P x R) or Max. Operating voltage whichever is lower.

☑ Storage Temperature: 15 ~ 28°C; Humidity < 80%RH

☑ Shelf Life: 2 years from production date.

1206 : 4 digits marking

Example:

| Resistance | 100Ω | 2.2KΩ | 10KΩ | 49.9KΩ | 100KΩ |

|---|---|---|---|---|---|

| Marking | 1000 | 2201 | 1002 | 4992 | 1003 |

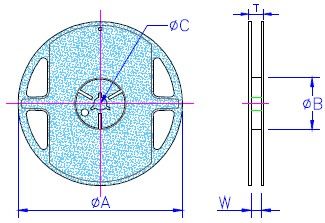

Packing Quantity & Reel Specifications (Unit :mm)

| Type | ØA | ØB | ØC | W | T | Paper Type(EA) | Emboss Plastic Tape(EA) |  |

|---|---|---|---|---|---|---|---|---|

| ARP06 | 178.0±1.0 | 60.0+1.0 | 13.5±0.7 | 9.5±1.0 | 11.5±1.0 | 5,000 | - |

Paper Tape Specifications

| Type | A | B | W | E | F | P0 | P1 | P2 | ΦD0 | T |

|---|---|---|---|---|---|---|---|---|---|---|

| ARP06 | 2.00±0.05 | 3.55±0.05 | 8.00±0.10 | 1.75±0.05 | 3.5±0.05 | 4.00±0.10 | 4.00±0.10 | 2.00±0.05 | 1.55±0.05 | 0.75±0.05 |

☑ Peel force of top cover tape

☑ The peel speed shall be about 300mm/min±5%

☑ The peel force of top cover tape shall be between 8gf to 60gf

Dunne film precisie weerstand 0,01%, TC2ppm, draadgebonden, anti-corrosief, MELF. Stroomdetectie, Metaal,...

Lees verder

Keramische hoogfrequente chip spoelen, klein formaat tot 01005. Dunne film, meerlaags, draadgewonden,...

Lees verder

Multilayer keramische condensator biedt hoge spanning, hoge frequentie, lage ruis, hoge Q, lage TCR....

Lees verder