AUTOMOBIEL TOEPASSINGEN

Dunne film precisie weerstand 0,01%, TC2ppm, draadgebonden, anti-corrosief, MELF. Stroomdetectie, Metaal,...

Lees verderDunne film hoge precisie weerstand, Algemeen gebruik voor nauwkeurige weerstanden met speciale constructie, Lage kosten en goede prestaties.

ARG Series1206 ±1% 50 1/4W Series57.6KΩ 5K/Reel

| Grootte | Tolerantie | TCR (ppm /℃) | Vermogen | Weerstand (Ohm) | Verpakking |

|---|---|---|---|---|---|

| 1206 | ±1% | 50 | 1/4W | 57.6K | 5K/Reel |

| Item | Requirement | Test Method |

|---|---|---|

| Temperature Coefficient of Resistance (T.C.R.) | As Spec. | MIL-STD-202 Method 304 +25/-55/+25/+125/+25°C |

| Short Time Overload | ΔR±0.2% | JIS-C-5201-1 4.13 RCWV*2.5 or Max. overload voltage whichever is lower for 5 seconds |

| Insulation Resistance | >9999 MΩ | MIL-STD-202 Method 302 Apply 100VDC for 1 minute |

| Endurance | ΔR±0.5% | MIL-STD-202 Method 108A 70±2°C, RCWV for 1000 hrs with 1.5 hrs “ON” and 0.5 hrs “OFF” |

| Damp Heat with Load | ΔR±0.5% | MIL-STD-202 Method 103B 40±2°C, 90~95% R.H. RCWV for 1000 hrs with 1.5 hrs “ON” and 0.5 hrs “OFF” |

| Bending Strength | ΔR±0.1% | JIS-C-5201-1 4.33 Bending amplitude 3 mm for 10 seconds |

| Solderability | 95% min. coverage | MIL-STD-202 Method 208H 245±5°C for 3 seconds |

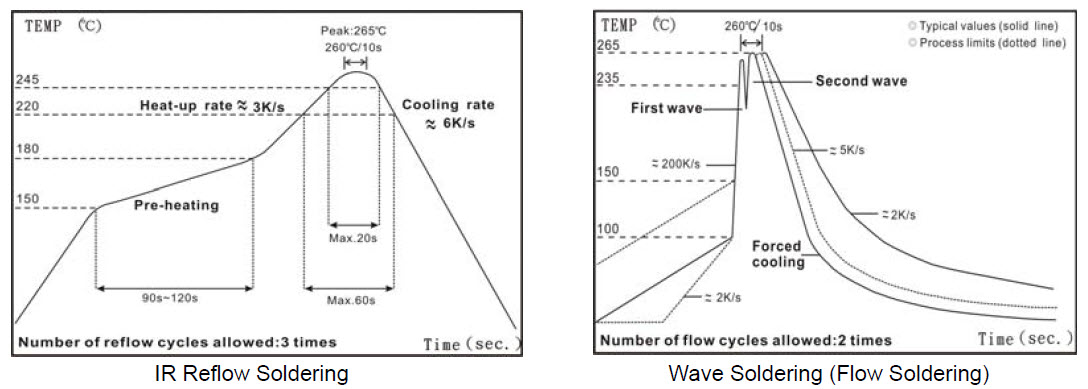

| Resistance to Soldering Heat | ΔR±0.1% | MIL-STD-202 Method 210E 260±5°C for 10 seconds |

| Dielectric Withstand Voltage | By Type | MIL-STD-202 Method 301 Max. overload voltage for 1 minute |

| Thermal Shock | ΔR±0.2% | MIL-STD-202 Method 107G -55°C ~150°C, 100 cycles |

| Low Temperature Operation | ΔR±0.5% | JIS-C-5201-1 4.36 1 hour, -65°C, followed by 45 minutes of RCWV |

| High Temperature Exposure | ΔR±0.5% | MIL-STD-202 Method 108 at 155°C for 1000 hrs |

RCWV(Rated continuous working voltage)= √(P*R) or Max. Operating voltage whichever is lower

☑ Storage Temperature: 15~28°C; Humidity < 80%RH

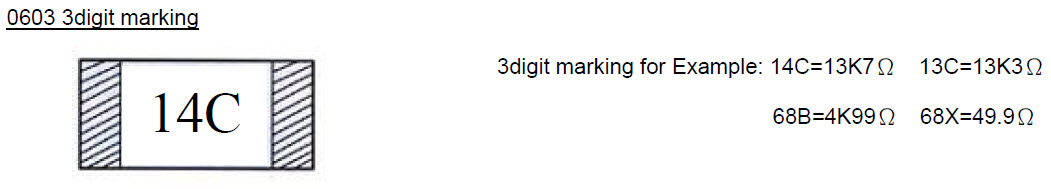

Marking Table

| Code | E96 | Code | E96 | Code | E96 | Code | E96 | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 01 | 100 | 25 | 178 | 49 | 316 | 73 | 562 | ||||

| 02 | 102 | 26 | 182 | 50 | 324 | 74 | 576 | ||||

| 03 | 105 | 27 | 187 | 51 | 332 | 75 | 590 | ||||

| 04 | 107 | 28 | 191 | 52 | 340 | 76 | 604 | ||||

| 05 | 110 | 29 | 196 | 53 | 348 | 77 | 619 | ||||

| 06 | 113 | 30 | 200 | 54 | 357 | 78 | 634 | ||||

| 07 | 115 | 31 | 205 | 55 | 365 | 79 | 649 | ||||

| 08 | 118 | 32 | 210 | 56 | 374 | 80 | 665 | ||||

| 09 | 121 | 33 | 215 | 57 | 383 | 81 | 681 | ||||

| 10 | 124 | 34 | 221 | 58 | 392 | 82 | 698 | ||||

| 11 | 127 | 35 | 226 | 59 | 402 | 83 | 715 | ||||

| 12 | 130 | 36 | 232 | 60 | 412 | 84 | 732 | ||||

| 13 | 133 | 37 | 237 | 61 | 422 | 85 | 750 | ||||

| 14 | 137 | 38 | 243 | 62 | 432 | 86 | 768 | ||||

| 15 | 140 | 39 | 249 | 63 | 442 | 87 | 787 | ||||

| 16 | 143 | 40 | 255 | 64 | 453 | 88 | 806 | ||||

| 17 | 147 | 41 | 261 | 65 | 464 | 89 | 825 | ||||

| 18 | 150 | 42 | 267 | 66 | 475 | 90 | 845 | ||||

| 19 | 154 | 43 | 274 | 67 | 487 | 91 | 866 | ||||

| 20 | 158 | 44 | 280 | 68 | 499 | 92 | 887 | ||||

| 21 | 162 | 45 | 287 | 69 | 511 | 93 | 909 | ||||

| 22 | 165 | 46 | 294 | 70 | 523 | 94 | 931 | ||||

| 23 | 169 | 47 | 301 | 71 | 536 | 95 | 953 | ||||

| 24 | 174 | 48 | 309 |

72 | 549 | 96 | 976 | ||||

| Code | A | B | C | D | E | F | G | H | X | Y | Z |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Multiplier | 10s0 | 101 | 102 | 103 | 104 | 105 | 106 | 107 | 10-1 | 10-2 | 10-3 |

0603 3digit marking for E24

Example: 101=100Ω 102=1KΩ

| E24 | 10 | 11 | 12 | 13 | 15 | 16 | 18 | 20 | 22 | 24 | 27 | 30 | 33 | 36 | 39 | 43 | 47 | 51 | 56 | 62 | 68 | 75 | 82 | 91 |

0805~2512 4digit marking

Example

| Resistance | 100Ω | 2.2KΩ | 10KΩ | 49.9KΩ | 100KΩ |

|---|---|---|---|---|---|

| marking | 1000 | 2201 | 1002 | 4992 | 1003 |

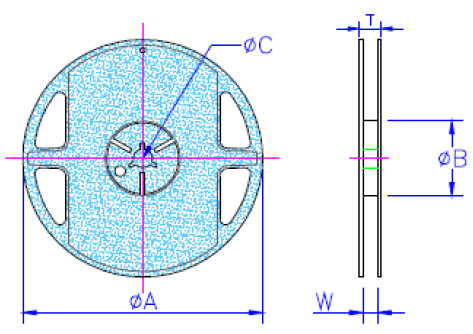

Packing Quantity & Reel Specifications (Unit :mm)

| Type | ØA | ØB | ØC | W | T | Paper Type(EA) | Emboss Plastic Tape(EA) |  |

|---|---|---|---|---|---|---|---|---|

| ARG02 | 178.0±1.0 | 60.0+1.0 | 13.5±0.7 | 9.5±1.0 | 11.5±1.0 | 10,000 | - | |

| ARG03 | 178.0±1.0 | 60.0+1.0 | 13.5±0.7 | 9.5±1.0 | 11.5±1.0 | 5,000 | - | |

| ARG05 | 178.0±1.0 | 60.0+1.0 | 13.5±0.7 | 9.5±1.0 | 11.5±1.0 | 5,000 | - | |

| ARG06 | 178.0±1.0 | 60.0+1.0 | 13.5±0.7 | 9.5±1.0 | 11.5±1.0 | 5,000 | - |

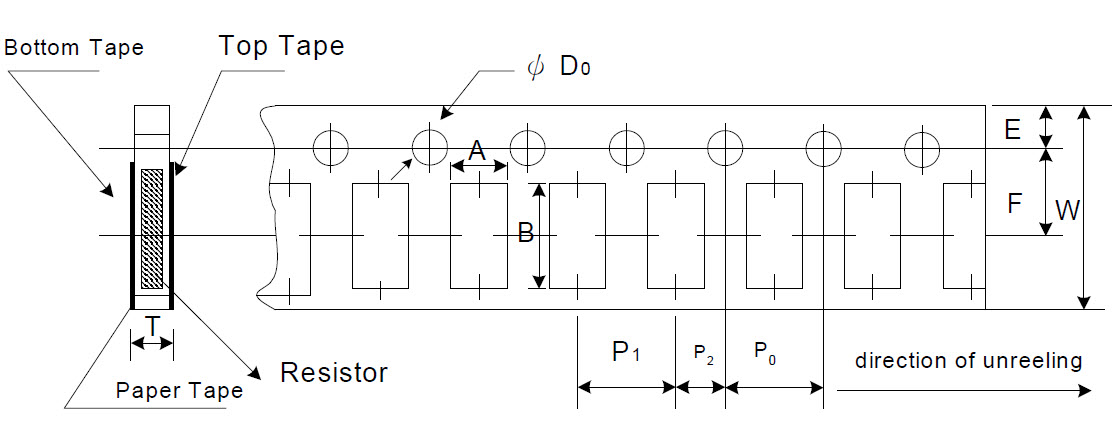

Paper Tape Specifications

| Type | A | B | W | E | F | P0 | P1 | P2 | ΦD0 | T |

|---|---|---|---|---|---|---|---|---|---|---|

| ARG02 | 0.70±0.05 | 1.16±0.05 | 8.00±0.10 | 1.75±0.05 | 3.5±0.05 | 4.00±0.10 | 2.00±0.05 | 2.00±0.05 | 1.55±0.05 | 0.40±0.03 |

| ARG03 | 1.10±0.05 | 1.90±0.05 | 8.00±0.10 | 1.75±0.05 | 3.5±0.05 | 4.00±0.10 | 4.00±0.10 | 2.00±0.05 | 1.55±0.05 | 0.60±0.03 |

| ARG05 | 1.60±0.05 | 2.37±0.05 | 8.00±0.10 | 1.75±0.05 | 3.5±0.05 | 4.00±0.10 | 4.00±0.10 | 2.00±0.05 | 1.55±0.05 | 0.75±0.05 |

| ARG06 | 2.00±0.05 | 3.55±0.05 | 8.00±0.10 | 1.75±0.05 | 3.5±0.05 | 4.00±0.10 | 4.00±0.10 | 2.00±0.05 | 1.55±0.05 | 0.75±0.05 |

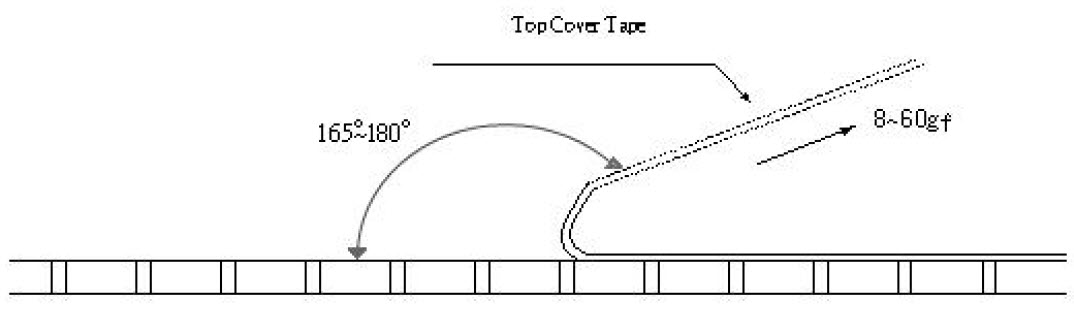

☑ Peel force of top cover tape

☑ The peel speed shall be about 300mm/min±5%

☑ The peel force of top cover tape shall be between 8gf to 60gf

Dunne film precisie weerstand 0,01%, TC2ppm, draadgebonden, anti-corrosief, MELF. Stroomdetectie, Metaal,...

Lees verder

Keramische hoogfrequente chip spoelen, klein formaat tot 01005. Dunne film, meerlaags, draadgewonden,...

Lees verder

Multilayer keramische condensator biedt hoge spanning, hoge frequentie, lage ruis, hoge Q, lage TCR....

Lees verder