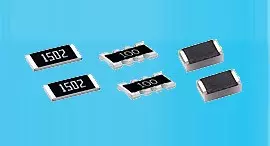

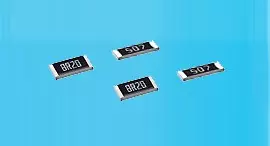

다층 세라믹 칩 커패시터 (MC 시리즈 MC03DTN5005R6)

MC03DTN5005R6

다층 세라믹 커패시터, MLCC, 다양한 크기와 재료로 다양한 용량을 지원하는 칩 커패시터, 매우 작은 크기, 낮은 인덕턴스와 고주파, 우수한 납땜성 및 납땜 저항성, 낮은 ESR, 모든 종류의 응용에 적합합니다. EIAJ-RC3402에 부합하며 EIA-RS198 및 IEC PUB. 384-10과도 호환됩니다.

MC Series0603 ±0.5pF 4K/Reel NPO 5.6pF 50V

| 크기 | 허용오차 | 패키지 | 유전율 | 정전 용량 (pF) | 전압 (V) |

|---|---|---|---|---|---|

| 0603 | ±0.5pF | 4K/Reel | NPO | 5.6 | 50 |

MCRF 시리즈를 위한 초고 Q 및 저 ESR 커패시터

Capacitance & Voltage

| Dielectric | NPO | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| EIA | Size | 0201 | 0402 | 0603 | 0805 | |||||||||||

| Code | VDCW | 6.3V | 10V | 25V | 50V | 25V | 50V | 100V | 200V | 50V | 100V | 250V | 50V | 100V | 250V | 500V |

| 0R1 | 0.1pF | L | L | L | L | N | N | N | N | |||||||

| 0R2 | 0.2 | L | L | L | L | N | N | N | N | |||||||

| 0R3 | 0.3 | L | L | L | L | N | N | N | N | S | S | S | T | T | T | T |

| 0R4 | 0.4 | L | L | L | L | N | N | N | N | S | S | S | T | T | T | T |

| 0R5 | 0.5 | L | L | L | L | N | N | N | N | S | S | S | T | T | T | T |

| 0R6 | 0.6 | L | L | L | L | N | N | N | N | S | S | S | T | T | T | T |

| 0R7 | 0.7 | L | L | L | L | N | N | N | N | S | S | S | T | T | T | T |

| 0R8 | 0.8 | L | L | L | L | N | N | N | N | S | S | S | T | T | T | T |

| 0R9 | 0.9 | L | L | L | L | N | N | N | N | S | S | S | T | T | T | T |

| 1R0 | 1.0 | L | L | L | L | N | N | N | N | S | S | S | T | T | T | T |

| 1R2 | 1.2 | L | L | L | L | N | N | N | N | S | S | S | T | T | T | T |

| 1R5 | 1.5 | L | L | L | L | N | N | N | N | S | S | S | T | T | T | T |

| 1R8 | 1.8 | L | L | L | L | N | N | N | N | S | S | S | T | T | T | T |

| 2R0 | 2.0 | L | L | L | L | N | N | N | N | S | S | S | T | T | T | T |

| 2R2 | 2.2 | L | L | L | L | N | N | N | N | S | S | S | T | T | T | T |

| 2R7 | 2.7 | L | L | L | L | N | N | N | N | S | S | S | T | T | T | T |

| 3R0 | 3.0 | L | L | L | L | N | N | N | N | S | S | S | T | T | T | T |

| 3R3 | 3.3 | L | L | L | L | N | N | N | N | S | S | S | T | T | T | T |

| 3R9 | 3.9 | L | L | L | L | N | N | N | N | S | S | S | T | T | T | T |

| 4R0 | 4.0 | L | L | L | L | N | N | N | N | S | S | S | T | T | T | T |

| 4R7 | 4.7 | L | L | L | L | N | N | N | N | S | S | S | T | T | T | T |

| 5R0 | 5.0 | L | L | L | L | N | N | N | N | S | S | S | T | T | T | T |

| 5R6 | 5.6 | L | L | L | L | N | N | N | N | S | S | S | T | T | T | T |

| 6R0 | 6.0 | L | L | L | L | N | N | N | N | S | S | S | T | T | T | T |

| 6R8 | 6.8 | L | L | L | L | N | N | N | N | S | S | S | T | T | T | T |

| 7R0 | 7.0 | L | L | L | L | N | N | N | N | S | S | S | T | T | T | T |

| 8R2 | 8.2 | L | L | L | L | N | N | N | N | S | S | S | T | T | T | T |

| 9R0 | 9.0 | L | L | L | L | N | N | N | N | S | S | S | T | T | T | T |

| 100 | 10 | L | L | L | L | N | N | N | N | S | S | S | T | T | T | T |

| 110 | 11 | L | L | L | L | N | N | N | N | S | S | S | T | T | T | T |

| 120 | 12 | L | L | L | L | N | N | N | N | S | S | S | T | T | T | T |

| 130 | 13 | L | L | L | L | N | N | N | N | S | S | S | T | T | T | T |

| 150 | 15 | L | L | L | L | N | N | N | N | S | S | S | T | T | T | T |

| 160 | 16 | L | L | L | L | N | N | N | N | S | S | S | T | T | T | T |

| 180 | 18 | L | L | L | L | N | N | N | N | S | S | S | T | T | T | T |

| 200 | 20 | L | L | L | L | N | N | N | N | S | S | S | T | T | T | T |

| 220 | 22 | L | L | L | N | N | N | N | S | S | S | T | T | T | T | |

| 240 | 24 | L | L | L | N | N | N | N | S | S | S | T | T | T | T | |

| 270 | 27 | L | L | L | N | N | N | N | S | S | S | T | T | T | T | |

| 300 | 30 | L | L | L | N | N | N | N | S | S | S | T | T | T | T | |

| 330 | 33 | L | L | L | N | N | N | S | S | S | T | T | T | T | ||

| 360 | 36 | N | N | N | S | S | S | T | T | T | T | |||||

| 390 | 39 | N | N | N | S | S | S | T | T | T | T | |||||

| 430 | 43 | N | N | N | S | S | S | T | T | T | T | |||||

| 470 | 47 | N | N | N | S | S | S | T | T | T | T | |||||

| 560 | 56 | N | S | S | S | T | T | T | T | |||||||

| 680 | 68 | N | S | S | S | T | T | T | T | |||||||

| 820 | 82 | N | S | S | S | T | T | T | ||||||||

| 101 | 100 | N | S | S | S | T | T | T | ||||||||

The letter in cell is expressed the symbol of product thickness.

Electrical Data

| Dielectric | NPO |

|---|---|

| Size | 0201, 0402, 0603, 0805 |

| Capacitance* | 0201: 0.1pF ~ 33pF , 0402: 0.1pF ~ 100pF 0603: 0.3pF ~ 100pF , 0805: 0.3pF ~ 100pF |

| Capacitance tolerance** | Cap ≦ 5pF: A (± 0.05pF), B (± 0.1pF), C (± 0.25pF) 5pF<Cap<10pF: B (± 0.1pF), C (± 0.25pF) , D (± 0.5pF) Cap ≧ 10pF: F (± 1%), G (± 2%), J (± 5%) |

| Rated voltage (VDCW) | 6.3V, 10V, 25V, 50V, 100V, 250V, 500V |

| Q * | Cap ≧ 30pF: Q ≧ 1000, Cap<30pF: Q ≧ 400+20C; |

| Insulation resistance at Ur | ≧ 10GΩ |

| Operating temperature | -55 to +125°C |

| Capacitance | ± 30 ppm; 0201 Cap ≧ 22pF, ± 60 ppm |

| Termination | Ni / Sn (lead-free termination) |

☑ '*' Measured at the conditions of 25°C ambient temperature and 30 ~ 70% related humidity.

☑ Apply 1.0 ± 0.2Vrms, 1.0MHz ± 10% for Cap ≦ 1000pF; 1.0KHz ± 10% for Cap>1000pF.

Electrical Characteristics

환경 특성

| Item | Requirement | Test Method | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| External Appearance | No defects which may affect performance | Visual inspection & Dimension measurement | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Capacitance(Cap.) | Within the specified tolerance that refers on page2 | NPO: (Class I) Cap ≤ 1000pF 1.0 ± 0.2Vrms, 1MHz ± 10% Cap>1000pF 1.0 ± 0.2Vrms, 1KHz ± 10% X7R, X5R, Y5V: (Class II) Cap ≤ 10uF 1.0 ± 0.2Vrms, 1KHz ± 10%** Cap>10uF 0.5 ± 0.2Vrms, 120Hz ± 10% ** Test condition: 0.5 ± 0.2Vrms,1KHz ± 10% X7R: 0805=106(6.3V, 10V), 0603/475 (6.3V) X5R: 0201 ≧ 224 (6.3V, 10V, 16V)#1 0402 ≧ 475 (6.3V, 16V), 0402 ≧ 225 (10V) 0603=106 (6.3V, 10V), #1 Excluding X5R / 0201 / 105 (6.3V); 225 (10V), (1.0 ± 0.2Vrms, 1KHz ± 10%) *Before initial measurement (Class II only): To apply de-aging at 150°C for 1hr then set for 24 ± 2 hrs at room temp. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Dissipation Factor (D.F.) or Quality factor (Q=1/D.F.) |

NPO: Cap ≥ 30pF, Q ≥ 1000; Cap<30pF, Q ≥ 400+20C X7R, X5R:

Y5V:

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Dielectric Strength | No evidence of damage or flash over during test | To apply voltage (≤ 100V) 250% Duration: 1 to 5sec Charge and discharge current less than 50mA To apply voltage: 200V ~ 300V ≧ 2 time VDC 500V ~ 999V ≧ 1.5 time VDC 1000V ~ 3000V ≧ 1.2 time VDC Cut-off, set at 10mA TEST=15 sec. RAMP=0 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Item | Requirement | Test Method | ||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Insulation Resistance | 10GΩ or R x C ≧ 500Ω-F Whichever is smaller X7R, X5R, Y5V:

|

To apply rated voltage for max. 120sec *Before initial measurement (Class II only): To apply de-aging at 150°C for 1hr then set for 24 ± 2 hrs at room temp. |

||||||||||||||||||||||||||||||||||||||||||||||

| ≧ 10GΩ or 100Ω-F whichever is smaller Rated voltage: 200V ~ 630V |

To apply rated voltage (500V max.) for 60sec. | |||||||||||||||||||||||||||||||||||||||||||||||

| ≧ 10GΩ Rated voltage: >630V |

To apply 500V for 60sec. | |||||||||||||||||||||||||||||||||||||||||||||||

| Temperature Characteristic of Capacitance |

|

With no electrical load.

*Before initial measurement (Class II only):

|

||||||||||||||||||||||||||||||||||||||||||||||

| Adhesive Strength of Termination | No remarkable damage or removal of the terminations | Pressurizing force: 0201: 2N 0402 & 0603: 5N > 0603: 10N Test time: 10 ± 1 sec |

||||||||||||||||||||||||||||||||||||||||||||||

| Vibration Resistance | No remarkable damage Cap change and Q/D.F.: To meet initial spec | Vibration frequency: 10 ~ 55Hz/min Total amplitude: 1.5mm Test time: 6hrs. (two hrs each in three mutually Perpendicular directions.) *Before initial measurement (Class II only): To apply de-aging at 150°C for 1hr then set for 24 ± 2 hrs at room temp. *Cap./DF(Q) Measurement to be made after de-aging at 150°C for 1hr then set for 24 ± 2 hrs at room temp. |

||||||||||||||||||||||||||||||||||||||||||||||

| Solderability | 95% min. coverage of all metalized area. | Solder temperature: 235 ± 5°C Dipping time: 2 ± 0.5 sec. |

| Item | Requirement | Test Method | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Bending Test | No remarkable damage. Cap change: NP0: within ± 5% or 0.5pF whichever is larger X7R, X5R, X6S, X7S: within ± 12.5% Y5V: within ± 30% (This capacitance change means the change of capacitance under specified flexure of substrate from the capacitance measured before the test.) |

The middle part of substrate shall be pressurized by means of the pressurizing rod at a rate of about 1 mm per second until the deflection becomes 1 mm and then the pressure shall be maintained for 5 ± 1 sec. * Before initial measurement (Class II only): To apply de-aging at 150°C for 1hr then set for 24 ± 2 hrs at room temp. Measurement to be made after keeping at room temp. for 24 ± 2 hrs. |

|||||||||||||||

| Resistance to Soldering Heat | No remarkable damage. Cap change: NP0: within ± 2.5% or 0.25pF whichever is larger X7R, X5R, X6S, X7S: within ± 7.5% Y5V: within ± 20% Q/D.F., I.R. and dielectric strength: To meet initial requirements. 25% max. leaching on each edge |

Solder temperature: 260 ± 5°C Dipping time: 10 ± 1 sec Preheating: 120 to 150°C for 1 minute before immerse the capacitor in a eutectic solder. * Before initial measurement (Class II only): To apply de-aging at 150°C for 1hr then set for 24 ± 2 hrs at room temp. Cap. / DF(Q) / I.R. Measurement to be made after de-aging at 150°C for 1hr then set for 24 ± 2 hrs at room temp |

|||||||||||||||

| Temperature Cycle | No remarkable damage. |

Conduct the five cycles according to the temperature and time.

Before initial measurement (Class II only): To apply de-aging at 150°C for 1hr then set for 24 ± 2 hrs at room temp. |

| Item | Requirement | Test Method | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Humidity (steady state) | No remarkable damage. Cap change: NP0: within ± 5% or 0.5pF whichever is larger X7R, X5R: ≥ 10V**,within ± 12.5%; ≦ 6.3V within ± 25%;C ≥ 1μF,within ± 25% **10V: 0603 ≧ 4.7μF;0402 ≧ 1μF;0201 ≧ 0.1μF, within ± 25%; Y5V: ≥ 10V, within ± 30%; ≦ 6.3V, within +30 / -40% Q/D.F. value: NP0: More than 30pF Q ≥ 350, 10pF ≦ C ≦ 30pF, Q ≥ 275 + 2.5C Less than 10pF Q ≥ 200+10C X7R, X5R:

Y5V:

I.R.: ≥ 10V, 1GΩ or 50 Ω-F whichever is smaller.

|

Test temp.: 40 ± 2°C Humidity: 90 ~ 95%RH Test time: 500 + 24 / -0hrs. Before initial measurement (Class II only): To apply de-aging at 150°C for 1hr then set for 24 ± 2 hrs at room temp. Cap. / DF(Q) / I.R. Measurement to be made after de-aging at 150°C for 1hr then set for 24 ± 2 hrs at room temp. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Item | Requirement | Test Method | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Humidity load | No remarkable damage. Cap change: NP0: ± 7.5% or 0.75pF whichever is larger. X7R, X5R, X6S, X7S: ≥ 10V**,within ± 12.5%; ≦ 6.3V within ± 25%; TT series & C ≥ 1uF,within ± 25% **10V: 0603 4.7μF;0402 1μF;0201 ≧ ≧ ≧ 0.1μF, within ± 25%; Y5V: ≥ 10V, within ± 30%; ≦ 6.3V, within +30 / -40% Q/D.F. value: NP0: C ≥ 30pF,Q ≥ 200;C<30pF, Q ≥ 100+10 / 3C X7R, X5R:

Y5V:

I.R.: ≥ 10V, 500MΩ or 25 Ω-F whichever is smaller.

|

Test temp.: 40 ± 2°C Humidity: 90 ~ 95%RH Test time: 500 + 24 / -0 hrs. To apply voltage: Rated voltage (MAX. 500V) Before initial measurement (Class II only): To apply de-aging at 150°C for 1hr then set for 24 ± 2 hrs at room temp. Cap. / DF(Q) / I.R. Measurement to be made after de-aging at 150°C for 1hr then set for 24 ± 2 hrs at room temp. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Item | Requirement | Test Method | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| High Temperature Load (Endurance) | No remarkable damage.

Y5V:

I.R.: ≥ 10V, 1GΩ or 50 Ω-F whichever is smaller.

|

Test temp.:

(6) 150% of rated voltage for below range

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

포장

Packaging Quantity (Unit: mm)

| Type | Thickness / Symbol | Packaging (7" Reel) | ||

|---|---|---|---|---|

| Paper Tape | Plastic Tape | |||

| 0201 | 0.30 ± 0.03 | L | 15K | - |

| 0.30 ± 0.05 | L | 15K | - | |

| 0.30 ± 0.09 | L | 15K | - | |

| 0402 | 0.50 ± 0.05 | N | 10K | - |

| 0.5+0.02/-0.05 | Q | 10K | - | |

| 0.50 ± 0.20 | E | 10K | - | |

| 0603 | 0.50 ± 0.10 | H | 4K | - |

| 0.80 ± 0.10 | S | 4K | - | |

| 0.80 +0.15 / -0.10 | X | 4K | - | |

| 0805 | 0.50 ± 0.10 | H | 4K | - |

| 0.60 ± 0.10 | A | 4K | - | |

| 0.80 ± 0.10 | B | 4K | - | |

| 0.85 ± 0.10 | T | 4K | - | |

| 1.25 ± 0.10 | D | - | 3K | |

| 1.25 ± 0.20 | I | - | 3K | |

| 1206 | 0.80 ± 0.10 | B | 4K | - |

| 0.85 ± 0.10 | T | 4K | - | |

| 0.95 ± 0.10 | C | - | 3K | |

| 1.15 ± 0.15 | J | - | 3K | |

| 1.25 ± 0.10 | D | - | 3K | |

| 1.60 ± 0.20 | G | - | 2K | |

| 1.60 +0.30 / -0.10 | P | - | 2K | |

| 1210 | 0.85 ± 0.10 | T | - | 3K |

| 0.95 ± 0.10 | C | - | 3K | |

| 1.25 ± 0.10 | D | - | 3K | |

| 1.60 ± 0.20 | G | - | 2K | |

| 2.00 ± 0.20 | K | - | 1K | |

| 2.50 ± 0.30 | M | - | 1K | |

| 2.50 ± 0.30 | M | - | 0.5K | |

| 1808 | 1.25 ± 0.10 | D | - | 2K |

| 1.10 ± 0.15 | F | - | 2K | |

| 1.60 ± 0.20 | G | - | 2K | |

| 2.00 ± 0.20 | K | - | 1K | |

1812 |

1.25 ± 0.10 | D | - | 1K |

| 1.60 ± 0.20 | G | - | 1K | |

| 2.00 ± 0.20 | K | - | 1K | |

| 2.50 ± 0.30 | M | - | 0.5K | |

| 2.80 ± 0.30 | U | - | 0.5K | |

| 0612 | 0.80 ± 0.10 | B | 4K | - |

Tape and Reel (Unit: mm)

| Type | Chip Size | |||||||

|---|---|---|---|---|---|---|---|---|

| 0201 | 0402 | 0603 | 0805 | 1206 0612 |

1210 | 1808 | 1812 | |

| ∅ C | 13.0 ± 1.0 | 13.0 ± 1.0 | 13.0 ± 1.0 | 13.0 ± 1.0 | 13.0 ± 1.0 | 13.0 ± 1.0 | 13.0 ± 1.0 | 13.0 ± 1.0 |

| W | 9.0 ± 1.0 | 9.0 ± 1.0 | 9.0 ± 1.0 | 9.0 ± 1.0 | 9.0 ± 1.0 | 9.0 ± 1.0 | 13.5 ± 1.0 | 13.5 ± 1.0 |

| ∅ A | 178 ± 1.0 (7") | 178 ± 1.0 (7") | 178 ± 1.0 (7") | 178 ± 1.0 (7") | 178 ± 1.0 (7") | 178 ± 1.0 (7") | 178 ± 1.0 (7") | 178 ± 1.0 (7") |

| ∅ B | 60.5 ± 1.0 (7") | 60.5 ± 1.0 (7") | 60.5 ± 1.0 (7") | 60.5 ± 1.0 (7") | 60.5 ± 1.0 (7") | 60.5 ± 1.0 (7") | 80.0 ± 1.0 (7") | 80.0 ± 1.0 (7") |

Plastic Tape Size Specification (Unit: mm)

| Type | 0805 | 1206 | 1210 | 1808 | 1812 | |||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Thickness | D | I | C | J | D | G | P | T | C | D | G | K | M | D | F | G | K | D | F | G | K | M | U | |

| A0 | <1.80 | <200 | <2.30 | <3.05 | <3.05 | <3.20 | <2.50 | <3.90 | ||||||||||||||||

| B0 | <2.70 | <3.70 | <4.00 | <3.80 | <3.80 | <3.95 | <5.30 | <5.30 | ||||||||||||||||

| T | 0.23 ± 0.10 | 0.23 ± 0.10 | 0.23 ± 0.10 | 0.23 ± 0.10 | 0.23 ± 0.10 | 0.23 ± 0.10 | 0.25 ± 0.10 | 0.25 ± 0.10 | ||||||||||||||||

| K0 | <2.50 | <2.50 | <2.50 | <1.50 | <2.50 | <3.00 | <2.50 | <2.50 | <3.50 | |||||||||||||||

| W | 8.00 ± 0.20 | 8.00 ± 0.20 | 8.00 ± 0.20 | 8.00 ± 0.20 | 8.00 ± 0.20 | 8.00 ± 0.20 | 12.0 ± 0.20 | 12.0 ± 0.20 | ||||||||||||||||

| P0 | 4.00 ± 0.10 | 4.00 ± 0.10 | 4.00 ± 0.10 | 4.00 ± 0.10 | 4.00 ± 0.10 | 4.00 ± 0.10 | 4.00 ± 0.10 | 4.00 ± 0.10 | ||||||||||||||||

| P1 | 4.00 ± 0.10 | 4.00 ± 0.10 | 4.00 ± 0.10 | 4.00 ± 0.10 | 4.00 ± 0.10 | 4.00 ± 0.10 | 4.00 ± 0.10 | 8.00 ± 0.10 | ||||||||||||||||

| P2 | 2.00 ± 0.05 | 2.00 ± 0.05 | 2.00 ± 0.05 | 2.00 ± 0.05 | 2.00 ± 0.05 | 2.00 ± 0.05 | 2.00 ± 0.10 | 2.00 ± 0.05 | ||||||||||||||||

| D0 | 1.50 + 0.1/-0 | 1.50 ± 0.05 | 1.50 + 0.1/-0 | 1.50 + 0.1/-0 | 1.50 + 0.1/-0 | 1.50 + 0.1/-0 | 1.50 + 0.1/-0 | 1.50 + 0.1/-0 | ||||||||||||||||

| D1 | 1.00 ± 0.10 | 1.00 ± 0.10 | 1.00 ± 0.10 | 1.00 ± 0.10 | 1.00 ± 0.10 | 1.00 ± 0.10 | 1.50 ± 0.10 | 1.50 ± 0.10 | ||||||||||||||||

| E | 1.75 ± 0.10 | 1.75 ± 0.10 | 1.75 ± 0.10 | 1.75 ± 0.10 | 1.75 ± 0.10 | 1.75 ± 0.10 | 1.75 ± 0.10 | 1.75 ± 0.10 | ||||||||||||||||

| F | 3.50 ± 0.05 | 3.50 ± 0.05 | 3.50 ± 0.05 | 3.50 ± 0.05 | 3.50 ± 0.05 | 3.50 ± 0.05 | 5.50 ± 0.10 | 5.50 ± 0.10 | ||||||||||||||||

Paper Tape Size Specification (Unit: mm)

| Type | 0201 | 0402 | 0603 | 0805 | 1206 / 0612 | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Thickness | L | N | E | S | H | X | A | H | B | T | B | T |

| A0 | 0.39 ± 0.07 | 0.70 ± 0.20 | 1.05 ± 0.30 | 1.50 ± 0.20 | 1.50 ± 0.20 | 1.90 ± 0.50 | ||||||

| B0 | 0.69 ± 0.07 | 1.20 ± 0.20 | 1.80 ± 0.30 | 2.30 ± 0.20 | 2.30 ± 0.20 | 3.50 ± 0.50 | ||||||

| T | ≦0.50 | ≦0.80 | ≦1.20 | ≦1.15 | ≦1.30 | ≦1.30 | ||||||

| W | 8.00 ± 0.10 | 8.00 ± 0.10 | 8.00 ± 0.10 | 8.00 ± 0.10 | 8.00 ± 0.10 | 8.00 ± 0.10 | ||||||

| P0 | 4.00 ± 0.10 | 4.00 ± 0.10 | 4.00 ± 0.10 | 4.00 ± 0.10 | 4.00 ± 0.10 | 4.00 ± 0.10 | ||||||

| P1 | 2.00 ± 0.05 | 2.00 ± 0.05 | 4.00 ± 0.10 | 4.00 ± 0.10 | 4.00 ± 0.10 | 4.00 ± 0.10 | ||||||

| P2 | 2.00 ± 0.05 | 2.00 ± 0.05 | 2.00 ± 0.05 | 2.00 ± 0.05 | 2.00 ± 0.05 | 2.00 ± 0.05 | ||||||

| D0 | 1.55 ± 0.05 | 1.55 ± 0.05 | 1.55 ± 0.05 | 1.55 ± 0.05 | 1.55 ± 0.05 | 1.50 ± 0.05 | ||||||

| E | 1.75 ± 0.05 | 1.75 ± 0.05 | 1.75 ± 0.05 | 1.75 ± 0.05 | 1.75 ± 0.05 | 1.75 ± 0.10 | ||||||

| F | 3.50 ± 0.05 | 3.50 ± 0.05 | 3.50 ± 0.05 | 3.50 ± 0.05 | 3.50 ± 0.05 | 3.50 ± 0.05 | ||||||

코드

- 5R6

- 파일 다운로드

-

주요 제품