질화 알루미늄 박막 정밀 칩 저항기 (ARN 시리즈 ARN06CTDS2802)

ARN06CTDS2802

알루미늄 나이트라이드 얇은 필름 정밀 칩 저항기 - ARN 시리즈

ARN Series1206 ±0.25% 50 2W Series28KΩ 5K/Reel

| 크기 | 허용오차 | TCR (ppm /℃) | 전력 | 저항 (옴) | 패키지 |

|---|---|---|---|---|---|

| 1206 | ±0.25% | 50 | 2W | 28K | 5K/Reel |

환경 특성

| Item | Requirement | Test Method |

|---|---|---|

| Temperature Coefficient of Resistance (T.C.R.) | As Spec. | MIL-STD-202 Method 304 +25/-55/+25/+125/+25°C |

| Short Time Overload(2) | ΔR±0.5% | Actual power handling capability is limited by the end user mounting process. As with any high power chip resistor the ability to remove the heat is critical to the overall performance of the device |

| Insulation Resistance | >9999 MΩ | MIL-STD-202 Method 302 Apply 100VDC for 1 minute |

| Endurance | ΔR±1% | MIL-STD-202 Method 108A 70±2°C, RCWV for 1000 hrs with 1.5 hrs “ON” and 0.5 hrs “OFF” |

| Damp Heat with Load | ΔR±0.4% | MIL-STD-202 Method 103B 40±2°C, 90~95% R.H. RCWV for 1000 hrs with 1.5 hrs “ON” and 0.5 hrs “OFF” |

| Solderability | 95% min. coverage | MIL-STD-202 Method 208H 245±5°C for 3 seconds |

| Resistance to Soldering Heat | ΔR±0.2% | MIL-STD-202 Method 210E 260±5°C for 10 seconds |

| Thermal Shock | ΔR±0.2% | MIL-STD-202 Method 107G -55°C ~155°C, 100 cycles |

| Low Temperature Operation | ΔR±0.2% | JIS-C-5201-1 4.36 1 hour, -65°C, followed by 45 minutes of RCWV |

| High Temperature Exposure | ΔR±0.2% | MIL-STD-202 Method 108 at 155°C for 1000 hrs |

RCWV(Rated continuous working voltage)= √(P*R) or Max. Operating voltage whichever is lower

☑ Storage Temperature: 15~28°C; Humidity < 80%RH

납땜 조건

(1) Time of IR reflow soldering at maximum temperature point 260°C:10s

(2) Time of wave soldering at maximum temperature point 260°C:10s

(3) Time of soldering iron at maximum temperature point 410°C:5s

마킹

1206 / 2512: 4 digits marking

Example:

| Resistance | 500Ω | 2.2KΩ | 10KΩ | 12.5KΩ |

|---|---|---|---|---|

| Marking | 5000 | 2201 | 1002 | 1252 |

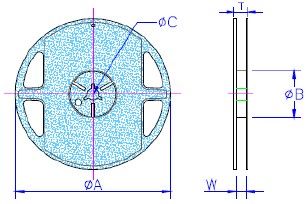

포장

Packing Quantity & Reel Specifications (Unit :mm)

| Type | ØA | ØB | ØC | W | T | Paper Type(EA) | Emboss Plastic Tape(EA) |  |

|---|---|---|---|---|---|---|---|---|

| ARN06 | 178.0±1.0 | 60.0+1.0 | 13.5±0.7 | 9.5±1.0 | 11.5±1.0 | 5,000 | - | |

| ARN12 | 178.0±1.0 | 60.0+1.0 | 13.5±0.7 | 13.5±1.0 | 15.5±1.0 | - | 4,000 |

Paper Tape Specifications

| Type | A | B | W | E | F | P0 | P1 | P2 | ΦD0 | T |

|---|---|---|---|---|---|---|---|---|---|---|

| ARN06 | 2.00±0.05 | 3.55±0.05 | 8.00±0.10 | 1.75±0.05 | 3.5±0.05 | 4.00±0.10 | 4.00±0.10 | 2.00±0.05 | 1.55±0.05 | 0.75±0.05 |

☑ Peel force of top cover tape

☑ The peel speed shall be about 300mm/min±5%

☑ The peel force of top cover tape shall be between 8gf to 60gf

Emboss Plastic Tape Specifications (Unit: mm)

| Type | A | B | W | E | F | P0 | P1 | P2 | ØD0 | T |

|---|---|---|---|---|---|---|---|---|---|---|

| ARN12 | 3.40±0.10 | 6.65±0.10 | 12.0±0.10 | 1.75±0.10 | 5.5±0.05 | 4.00±0.10 | 4.00±0.10 | 2.00±0.05 | 1.50±0.10 | 1.00±0.20 |

☑ Peel force of top cover tape

☑ The peel speed shall be about 300mm/min±5%

☑ The peel force of top cover tape shall be between 20gf to 80gf

주요 제품