自動車アプリケーション

薄膜精密抵抗器0.01%、TC2ppm、ワイヤーボンダブル、防錆性、MELF。 電流センシング、金属、耐硫黄、サージ、高電圧、TO220/247パッケージ最大100Wまで

続きを読むシールド付きSMD小型、ミニチュアパワーインダクター、低コスト、低プロファイル、高電流、磁気シールド構造のための新しい設計端子。デジタル機器やハンドセットに最適です。

SCDS Series6D28 ±30% 6.8μH 0.052 Ω 2.2A

| サイズ | 公差 | インダクタンス | 試験条件 | DCR (Ω) 最大 | IDC (A) |

|---|---|---|---|---|---|

| 6D28 | ±30% | 6.8 | 10KHz, 0.1V | 0.052 | 2.2 |

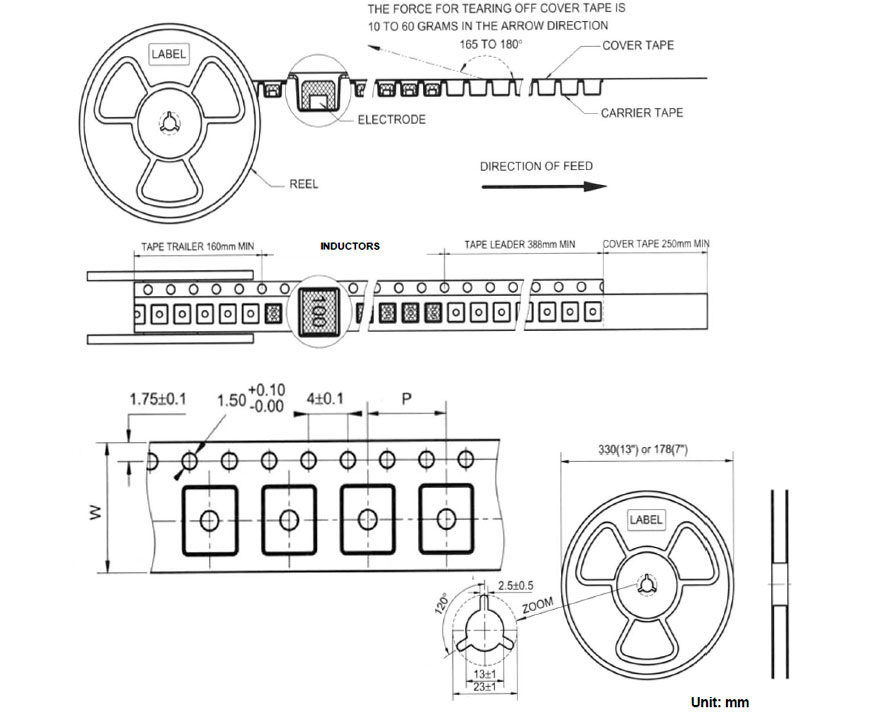

| Type | Tape size | Parts Per Reel | ||

|---|---|---|---|---|

| W | P | 7" | 13" | |

| SCDS3D18 | 12 | 8 | 1000 | - |

| SCDS4D18 | 12 | 8 | - | 2000 |

| SCDS4D28 | 12 | 8 | - | 2000 |

| SCDS5D18 | 12 | 8 | - | 2000 |

| SCDS5D28 | 12 | 8 | - | 2000 |

| SCDS6D28 | 16 | 12 | - | 1500 |

| SCDS6D38 | 16 | 12 | - | 1000 |

General

| Item | Specification |

|---|---|

| Shelf Storage conditions | Temperature range: 15 ~ 28°C; Humidity: <80% relative humidity. Recommended product should be used within one year from the time of delivery. |

Environmental Test

| Test Items | Specification | Test Conditions / Test Methods |

|---|---|---|

| High temperature Storage test | No case deformation or change in appearance. Δ L/L ≤10% |

Temperature 85 ± 2°C, Time: 48 ± 2 hours, Tested after 1hour at room temperature. |

| Low temperature Storage test | Temperature -25 ± 2°C, Time: 48 ± 2 hours, Tested after 1hour at room temperature. |

|

| Humidity test | Temperature 40 ± 2°C, 90 ~ 95% relative humidity Time: 96 ± 2 hours Tested after 1hour at room temperature. |

|

| Thermal shock test | First -25°C 30minutes then 25°C 10 minutes last 85°C 30 minutes, as 1 cycle. Go through 5 cycles. Tested after 1 hour at room temperature. |

Mechanical Test

| Test Items | Specification | Test Conditions / Test Methods |

|---|---|---|

| Solder Ability Test | Terminal area must have 90% minimum solder coverage. | Dip pads in flux then dip in solder pot (SnCuNi) at 245 ± 5°C for 3 seconds. |

| Resistance to Soldering Heat | No case deformation or change in appearance. | Flux should cover the whole of the sample before heating, then be preheated for about 2 minutes over temperature of 130 ~ 150°C. Immersing to 260 ± 5°C for 10 seconds. |

| Vibration test | No case deformation or change in appearance. Δ L/L ≤10% |

Apply frequency 10 ~ 55Hz. 1.5mm amplitude in each of perpendicular direction for 2 hours. |

| Shock resistance | Drop down with 981m/s² (100G) shock attitude upon a rubber block method shock testing machine, for 1 time. In each of three orientations. |

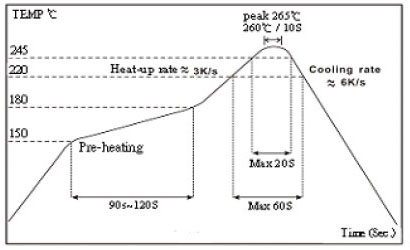

The Condition Of Reflow (Recommendation):

薄膜精密抵抗器0.01%、TC2ppm、ワイヤーボンダブル、防錆性、MELF。 電流センシング、金属、耐硫黄、サージ、高電圧、TO220/247パッケージ最大100Wまで

続きを読む