自動車アプリケーション

薄膜精密抵抗器0.01%、TC2ppm、ワイヤーボンダブル、防錆性、MELF。 電流センシング、金属、耐硫黄、サージ、高電圧、TO220/247パッケージ最大100Wまで

続きを読む金属抵抗器

大電流を検知するための金属ストリップ超低オーム抵抗器、高温に耐える。高温における安定した抵抗変動のための低温係数。

LR Series2512 ±5% 150 1W Series3.5mΩ

| サイズ | 公差 | TCR (ppm /℃) | 電力 | 抵抗 (オーム) |

|---|---|---|---|---|

| 2512 | ±5% | 150 | 1W | 3.5m |

| Item Part No. | Power Rating at 70°C | Operating Temp. Range | Resistance Range (mΩ) | TCR (PPM/°C) | ||

|---|---|---|---|---|---|---|

| ±1% | ±3% | ±5% | ||||

| LR12□TDS□□□□ | 2W | -55 ~ +155°C | 0.5, 0.75, 1, 1.5, 2 | ±50 | ||

| LR12□TWS□□□□ | 2W | -55 ~ +155°C | 6, 6.5, 7 | ±75 | ||

| LR12□TES□□□□ | 2W | -55 ~ +155°C | 4, 5, 10 | ±100 | ||

| LR12□TKS□□□□ | 2W | -55 ~ +155°C | 2.5, 3 | ±150 | ||

Operating Current =√(P/R), Operating Voltage=√(P*R)

☑ Viking has the ability of manufacture following options based on customer's requirement..

| Resistance | 1mΩ | 2mΩ | 7mΩ | 10mΩ |

|---|---|---|---|---|

| Codes | R001 | R002 | R007 | R010 |

| Item/th> | Requirement | Test Method |

|---|---|---|

| Temperature Coefficient of Resistance (T.C.R.) | As Spec. | MIL-STD-202 Method 304 +25~125°C, 25°C is the reference temperature |

| Short Time Overload | ±0.5% | JIS-C-5201-1 5.5 5*rated power for 5 seconds |

| ±1% | MIL-STD-202 Method 108A 70±2°C, RCWV for 1000 hrs with 1.5 hrs “ON” and 0.5 hr “OFF” | |

| Dry Heat | ±1% | JIS-C-5201-1 7.2 at +170°C for 1000 hrs |

| Solderability | 95% min. coverage | MIL-STD-202 Method 208H 245±5°C for 3 seconds |

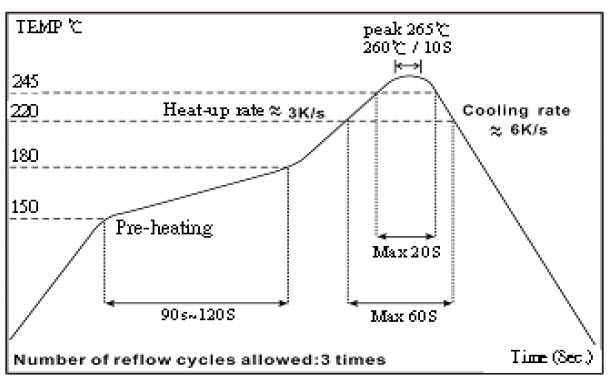

| Resistance to Soldering Heat | ±0.5% | MIL-STD-202 Method 210E 260±5°C for 10 seconds |

| Thermal Shock | ±0.5% | MIL-STD-202 Method 107G -55°C ~ 150°C, 100 cycles |

RCWV(Rated Continuous Working Voltage)= √(P*R) or Max. Operating Voltage whichever is lower.

☑ Storage Temperature: 15~28°C; Humidity < 80%RH

☑ Green coating ”Reflow Air Convection ”is available

☑ Green coating can't be working with wave soldering bath

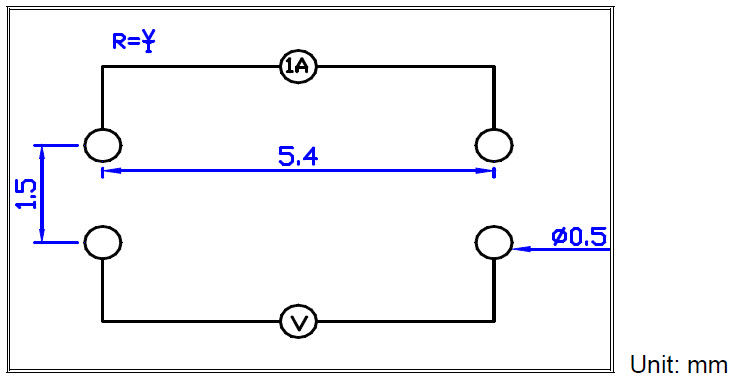

1. LR12 4-wire precision measurement (Black Coating)

■ Equipment: ADEX AX-1152D DC Low Ohm Meter

■ Excitation Current: 3A (0.5mΩ~1.5 mΩ)

1A (2mΩ~10mΩ)

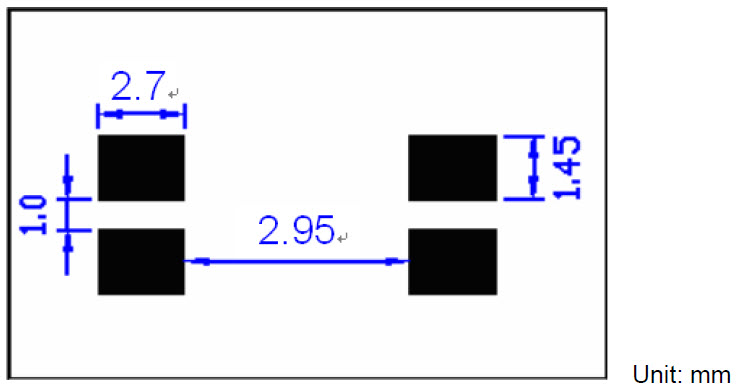

2. LR12 4-wire pad layout (recommended for precision current sensing)

■ Note: No circuits between pads to avoid short circuit

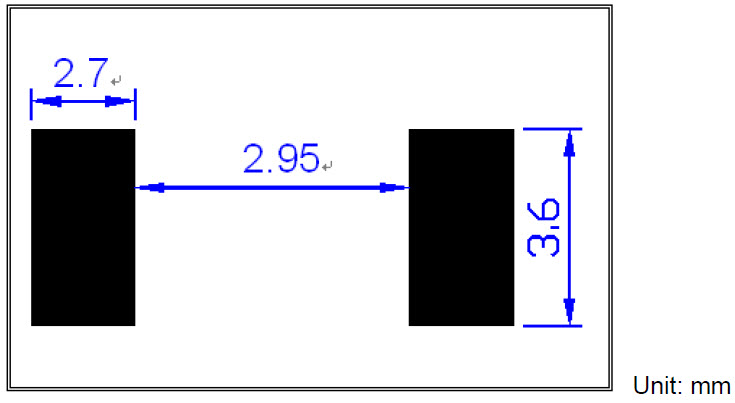

3. LR12 2-wire pad layout

■ Note: No circuits between pads to avoid short circuit

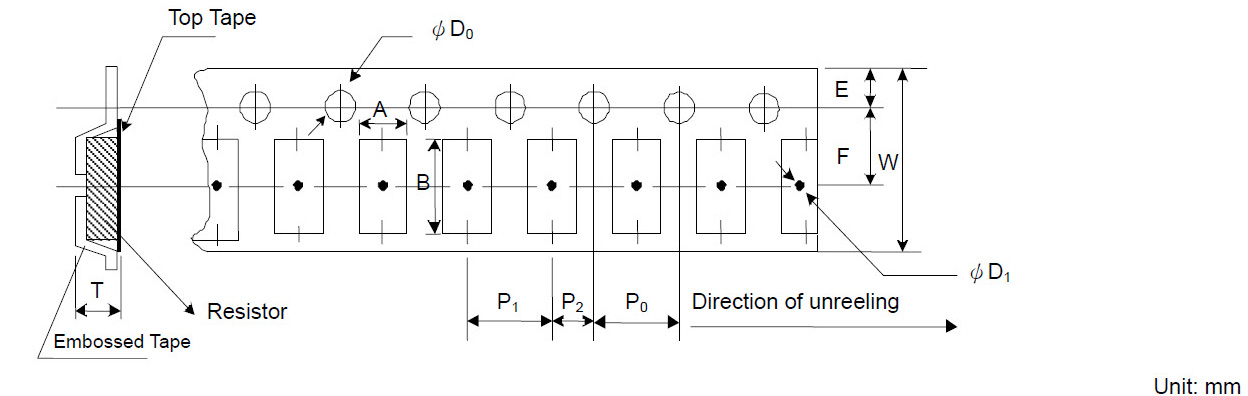

Embossed Plastic Tape Specifications

| Type | Resistance (mΩ) | A | B | W | E | F | P0 | P1 | P2 | ΦD0 | ΦD1 | T | Quantity (EA) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| LR06 | 0.5 - 10 | 1.90±0.1 | 3.60±0.1 | 8.0±0.2 | 1.75±0.1 | 3.5±0.05 | 4.0±0.1 | 4.0±0.1 | 2.0±0.05 | 1.55±0.05 | 1.0min. | 0.87±0.1 | 2,000 |

| LR10 | 0.5 - 10 | 2.85±0.1 | 5.55±0.1 | 12.0±0.2 | 1.75±0.1 | 5.5±0.05 | 4.0±0.1 | 4.0±0.1 | 2.0±0.05 | 1.55±0.05 | 1.4min. | 0.85±0.1 | 2,000 |

| LR12 | 0.50 - 0.75 | 3.40±0.1 | 6.75±0.1 | 12.0±0.1 | 1.75±0.1 | 5.5±0.05 | 4.0±0.1 | 4.0±0.1 | 2.0±0.05 | 1.55±0.05 | 1.4min. | 1.45±0.2 | 2,000 |

| 1 - 10 | 0.81±0.1 |

薄膜精密抵抗器0.01%、TC2ppm、ワイヤーボンダブル、防錆性、MELF。 電流センシング、金属、耐硫黄、サージ、高電圧、TO220/247パッケージ最大100Wまで

続きを読む