AUTOMOTIVE APPLICATIONS

Thin film Precision resistor 0.01%, TC2ppm, wirebondale, Anti-Crossive, MELF. Current sensing, Metal...

Read MoreAluminum Nitride Thin Film Precision Chip Resistor - ARN Series

ARN Series0603 ±0.5% 50 1/2W Series9.31KΩ 5K/Reel

| Size | Tolerance | TCR (ppm /℃) | Power | Resistance (Ohm) | Package |

|---|---|---|---|---|---|

| 0603 | ±0.5% | 50 | 1/2W | 9.31K | 5K/Reel |

| Item | Requirement | Test Method |

|---|---|---|

| Temperature Coefficient of Resistance (T.C.R.) | As Spec. | MIL-STD-202 Method 304 +25/-55/+25/+125/+25°C |

| Short Time Overload(2) | ΔR±0.5% | Actual power handling capability is limited by the end user mounting process. As with any high power chip resistor the ability to remove the heat is critical to the overall performance of the device |

| Insulation Resistance | >9999 MΩ | MIL-STD-202 Method 302 Apply 100VDC for 1 minute |

| Endurance | ΔR±1% | MIL-STD-202 Method 108A 70±2°C, RCWV for 1000 hrs with 1.5 hrs “ON” and 0.5 hrs “OFF” |

| Damp Heat with Load | ΔR±0.4% | MIL-STD-202 Method 103B 40±2°C, 90~95% R.H. RCWV for 1000 hrs with 1.5 hrs “ON” and 0.5 hrs “OFF” |

| Solderability | 95% min. coverage | MIL-STD-202 Method 208H 245±5°C for 3 seconds |

| Resistance to Soldering Heat | ΔR±0.2% | MIL-STD-202 Method 210E 260±5°C for 10 seconds |

| Thermal Shock | ΔR±0.2% | MIL-STD-202 Method 107G -55°C ~155°C, 100 cycles |

| Low Temperature Operation | ΔR±0.2% | JIS-C-5201-1 4.36 1 hour, -65°C, followed by 45 minutes of RCWV |

| High Temperature Exposure | ΔR±0.2% | MIL-STD-202 Method 108 at 155°C for 1000 hrs |

RCWV(Rated continuous working voltage)= √(P*R) or Max. Operating voltage whichever is lower

☑ Storage Temperature: 15~28°C; Humidity < 80%RH

1206 / 2512: 4 digits marking

Example:

| Resistance | 500Ω | 2.2KΩ | 10KΩ | 12.5KΩ |

|---|---|---|---|---|

| Marking | 5000 | 2201 | 1002 | 1252 |

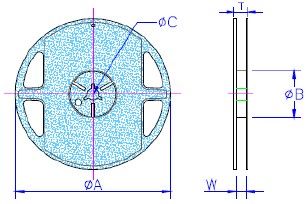

Packing Quantity & Reel Specifications (Unit :mm)

| Type | ØA | ØB | ØC | W | T | Paper Type(EA) | Emboss Plastic Tape(EA) |  |

|---|---|---|---|---|---|---|---|---|

| ARN06 | 178.0±1.0 | 60.0+1.0 | 13.5±0.7 | 9.5±1.0 | 11.5±1.0 | 5,000 | - | |

| ARN12 | 178.0±1.0 | 60.0+1.0 | 13.5±0.7 | 13.5±1.0 | 15.5±1.0 | - | 4,000 |

Paper Tape Specifications

| Type | A | B | W | E | F | P0 | P1 | P2 | ΦD0 | T |

|---|---|---|---|---|---|---|---|---|---|---|

| ARN06 | 2.00±0.05 | 3.55±0.05 | 8.00±0.10 | 1.75±0.05 | 3.5±0.05 | 4.00±0.10 | 4.00±0.10 | 2.00±0.05 | 1.55±0.05 | 0.75±0.05 |

☑ Peel force of top cover tape

☑ The peel speed shall be about 300mm/min±5%

☑ The peel force of top cover tape shall be between 8gf to 60gf

Emboss Plastic Tape Specifications (Unit: mm)

| Type | A | B | W | E | F | P0 | P1 | P2 | ØD0 | T |

|---|---|---|---|---|---|---|---|---|---|---|

| ARN12 | 3.40±0.10 | 6.65±0.10 | 12.0±0.10 | 1.75±0.10 | 5.5±0.05 | 4.00±0.10 | 4.00±0.10 | 2.00±0.05 | 1.50±0.10 | 1.00±0.20 |

☑ Peel force of top cover tape

☑ The peel speed shall be about 300mm/min±5%

☑ The peel force of top cover tape shall be between 20gf to 80gf

Thin film Precision resistor 0.01%, TC2ppm, wirebondale, Anti-Crossive, MELF. Current sensing, Metal...

Read More

Ceramic high frequency chip inductors, small size to 01005. Thin film, multilayer, wirewound , ferrite...

Read More

Multilayer Ceramic capacitor offers high Voltage, high frequency, low noise, High Q, Low TCR. NPO, X7R,...

Read More