AUTOMOTIVE APPLICATIONS

Thin film Precision resistor 0.01%, TC2ppm, wirebondale, Anti-Crossive, MELF. Current sensing, Metal...

Read MoreThin Film Precision Chip Resistor - AR Series

ARBTC Series0201 ±0.25% 25 1/20W Series12.1KΩ 10K/Reel

| Size | Tolerance | TCR (ppm /℃) | Power | Resistance (Ohm) | Package |

|---|---|---|---|---|---|

| 0201 | ±0.25% | 25 | 1/20W | 12.1K | 10K/Reel |

| Item | Power Rating at 70℃ | Operating Temp. Range | Max. Operating Voltage | Max. Overload Voltage | Resistance Range | TCR (PPM/℃) | |||||

| Type | ±0.01% | ±0.05% | ±0.1% | ±0.25% | ±0.5% | ±1% | |||||

| AR01 (0201) | 1/20W | -55 ~ +155℃ | 25V | 50V | - | 22Ω - 75KΩ | ±25 ±50 |

||||

| AR02 (0402) | 1/10W | -55 ~ +155℃ | 50V | 100V | 49.9Ω - 4.99KΩ | - | ±1 ±2 ±3 |

||||

| 49.9Ω - 20KΩ | ±5 | ||||||||||

| 49.9Ω - 12KΩ | 49.9Ω - 100KΩ | ±10 ±15 |

|||||||||

| - | 49.9Ω - 12KΩ | 4.7Ω~255KΩ | ±25 ±50 |

||||||||

| AR03 (0603) | 1/10W | -55 ~ +155℃ | 75V | 150V | 24.9Ω - 15KΩ | - | ±1 ±2 ±3 |

||||

| 24.9Ω - 60KΩ | ±5 | ||||||||||

| 24.9Ω - 100KΩ | 4.7Ω - 332KΩ | 4.7Ω - 511KΩ | ±10 ±15 |

||||||||

| 1Ω -1MΩ | ±25 ±50 |

||||||||||

| 1/6W | -55 ~ +155℃ | 100V | 150V | - | 10Ω - 332KΩ | ±25 ±50 |

|||||

| AR05 (0805) | 1/8W | -55 ~ +155℃ | 150V | 300V | 24.9Ω - 30KΩ | - | ±1 ±2 ±3 |

||||

| 24.9Ω - 150KΩ | ±5 | ||||||||||

| 24.9Ω - 200KΩ | 4.7Ω -511KΩ | 4.7Ω -1MΩ | ±10 ±15 |

||||||||

| 1Ω - 2MΩ | ±25 ±50 |

||||||||||

| 1/4W | -55 ~ +155℃ | 150V | 300V | - | 10Ω - 499KΩ | ±25 ±50 |

|||||

| AR06 (1206) | 1/4W | -55 ~ +155℃ | 200V | 400V | 24.9Ω - 49.9KΩ | - | ±1 ±2 ±3 |

||||

| 24.9Ω - 300KΩ | ±5 | ||||||||||

| 24.9Ω - 499KΩ | 4.7Ω - 1MΩ | ±10 ±15 |

|||||||||

| 1Ω - 2MΩ | ±25 ±50 |

||||||||||

| 1/3W | -55 ~ +155℃ | 200V | 400V | - | 10Ω ~1MΩ | ±25 ±50 |

|||||

| AR13 (1210) | 1/ 3W | -55 ~ +155℃ | 200V | 400V | 24.9Ω – 49.9KΩ | - | ±1 ±2 ±3 |

||||

| 24.9Ω – 300KΩ | ±5 | ||||||||||

| 24.9Ω - 499KΩ | 4.7Ω - 1MΩ | ±10 ±15 |

|||||||||

| 1Ω - 2MΩ | ±25 ±50 |

||||||||||

| AR10(2010) | 1/3W | -55 ~ +155℃ | 200V | 400V | 24.9Ω - 49.9KΩ | - | ±1 ±2 ±3 |

||||

| 24.9Ω - 300KΩ | ±5 | ||||||||||

| 24.9Ω - 499KΩ | 4.7Ω - 1MΩ | ±10 ±15 |

|||||||||

| 1Ω - 2MΩ | ±25 ±50 |

||||||||||

| 1/2W | -55 ~ +155℃ | 200V | 400V | 24.9Ω - 2KΩ | 4.7Ω – 1MΩ | 1Ω – 1MΩ | ±10 ±15 ±25 ±50 |

||||

| AR12(2512) | 3/4W | -55 ~ +155℃ | 200V | 400V | 24.9Ω - 2KΩ | 4.7Ω – 2KΩ | 1Ω – 2KΩ | ±10 ±15 ±25 ±50 |

|||

| 1W | -55 ~ +155℃ | 200V | 400V | 24.9Ω - 2KΩ | 4.7Ω – 1MΩ | 1Ω – 1MΩ | ±10 ±15 ±25 ±50 |

||||

Operating Voltage=√(P*R) or Max. operating voltage listed above, whichever is lower.

Overload Voltage=2.5*√(P*R) or Max. overload voltage listed above, whichever is lower.

☑ Viking is capable of manufacturing the optional spec based on customer's requirement.

(Lower Resistance:1~10Ω ; High Power Rating)

| Item | Requirement | Test Method | |

|---|---|---|---|

| Tol. ≦ 0.05% | Tol. > 0.05%/th> | ||

| Temperature Coefficient of Resistance (T.C.R.) | As Spec. | MIL-STD-202 Method 304 +25/-55/+25/+125/+25°C |

|

| Short Time Overload | ΔR±0.05% | ΔR±0.2% | JIS-C-5201-1 4.13 RCWV*2.5 or Max. overload voltage whichever is lower for 5 seconds |

| ΔR±0.2% for high power rating | |||

| Insulation Resistance | >9999 MΩ | MIL-STD-202 Method 302 Apply 100VDC for 1 minute |

|

| Endurance | ΔR±0.05% | ΔR±0.2% | MIL-STD-202 Method 108A 70±2°C, RCWV for 1000 hrs with 1.5 hrs “ON” and 0.5 hrs “OFF” |

| 0201: >7kΩ ΔR±0.5% ≦7kΩ ΔR±0.2% |

|||

| ΔR±0.5% for high power rating | |||

| Damp Heat with Load | ΔR±0.05% | ΔR±0.3% | MIL-STD-202 Method 103B 40±2°C, 90~95% R.H. RCWV for 1000 hrs with 1.5 hrs “ON” and 0.5 hrs “OFF” |

| ΔR±0.5% for high power rating | |||

| Bending Strength | ΔR±0.05% | ΔR±0.1% | JIS-C-5201-1 4.33 Bending once for 60 seconds 2010, 2512: 2mm other sizes: 3mm |

| Solderability | 95% min. coverage | MIL-STD-202 Method 208H 245±5°C for 3 seconds |

|

| Resistance to Soldering Heat | ΔR±0.05% | ΔR±0.1% | MIL-STD-202 Method 210E 260±5°C for 10 seconds |

| Dielectric Withstand Voltage | By Type | MIL-STD-202 Method 301 Max. overload voltage for 1 minute |

|

| Thermal Shock | ΔR±0.05% | ΔR±0.2% | MIL-STD-202 Method 107G -55°C ~150°C, 100 cycles |

| Low Temperature Operation | ΔR±0.05% | ΔR±0.2% | JIS-C-5201-1 4.36 1 hour, -65°C, followed by 45 minutes of RCWV |

| ΔR±0.5% for high power rating | |||

| High Temperature Exposure | ΔR±0.5% | MIL-STD-202 Method 108 at +155°C for 1000 hrs |

|

RCWV(Rated continuous working voltage)= √(P*R) or Max. Operating voltage whichever is lower

☑ Storage Temperature: 15~28°C; Humidity < 80%RH

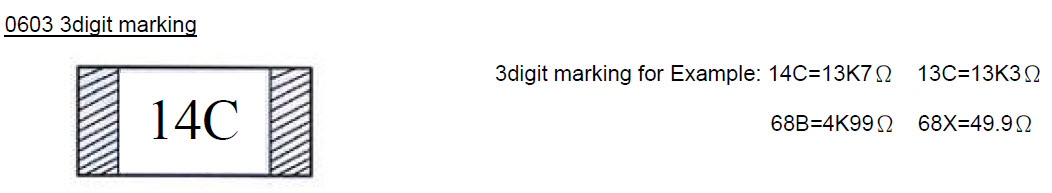

Marking Table

| Code | E96 | Code | E96 | Code | E96 | Code | E96 | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 01 | 100 | 25 | 178 | 49 | 316 | 73 | 562 | ||||

| 02 | 102 | 26 | 182 | 50 | 324 | 74 | 576 | ||||

| 03 | 105 | 27 | 187 | 51 | 332 | 75 | 590 | ||||

| 04 | 107 | 28 | 191 | 52 | 340 | 76 | 604 | ||||

| 05 | 110 | 29 | 196 | 53 | 348 | 77 | 619 | ||||

| 06 | 113 | 30 | 200 | 54 | 357 | 78 | 634 | ||||

| 07 | 115 | 31 | 205 | 55 | 365 | 79 | 649 | ||||

| 08 | 118 | 32 | 210 | 56 | 374 | 80 | 665 | ||||

| 09 | 121 | 33 | 215 | 57 | 383 | 81 | 681 | ||||

| 10 | 124 | 34 | 221 | 58 | 392 | 82 | 698 | ||||

| 11 | 127 | 35 | 226 | 59 | 402 | 83 | 715 | ||||

| 12 | 130 | 36 | 232 | 60 | 412 | 84 | 732 | ||||

| 13 | 133 | 37 | 237 | 61 | 422 | 85 | 750 | ||||

| 14 | 137 | 38 | 243 | 62 | 432 | 86 | 768 | ||||

| 15 | 140 | 39 | 249 | 63 | 442 | 87 | 787 | ||||

| 16 | 143 | 40 | 255 | 64 | 453 | 88 | 806 | ||||

| 17 | 147 | 41 | 261 | 65 | 464 | 89 | 825 | ||||

| 18 | 150 | 42 | 267 | 66 | 475 | 90 | 845 | ||||

| 19 | 154 | 43 | 274 | 67 | 487 | 91 | 866 | ||||

| 20 | 158 | 44 | 280 | 68 | 499 | 92 | 887 | ||||

| 21 | 162 | 45 | 287 | 69 | 511 | 93 | 909 | ||||

| 22 | 165 | 46 | 294 | 70 | 523 | 94 | 931 | ||||

| 23 | 169 | 47 | 301 | 71 | 536 | 95 | 953 | ||||

| 24 | 174 | 48 | 309 |

72 | 549 | 96 | 976 | ||||

| Code | A | B | C | D | E | F | G | H | X | Y | Z |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Multiplier | 10s0 | 101 | 102 | 103 | 104 | 105 | 106 | 107 | 10-1 | 10-2 | 10-3 |

0603 3digit marking for E24

Example: 101=100Ω 102=1KΩ

| E24 | 10 | 11 | 12 | 13 | 15 | 16 | 18 | 20 | 22 | 24 | 27 | 30 | 33 | 36 | 39 | 43 | 47 | 51 | 56 | 62 | 68 | 75 | 82 | 91 |

0805~2512 4digit marking

Example

| Resistance | 100Ω | 2.2KΩ | 10KΩ | 49.9KΩ | 100KΩ |

|---|---|---|---|---|---|

| marking | 1000 | 2201 | 1002 | 4992 | 1003 |

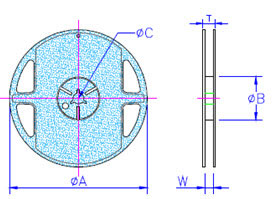

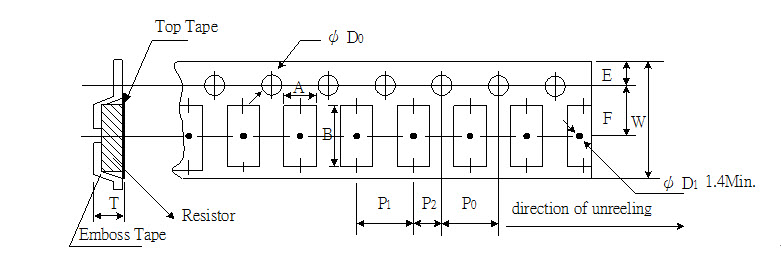

Packing Quantity & Reel Specifications (Unit :mm)

| Type | ØA | ØB | ØC | W | T | Paper Type(EA) | Emboss Plastic Tape(EA) |  |

|---|---|---|---|---|---|---|---|---|

| AR01 | 178.0±1.0 | 60.0+1.0 | 13.5±0.7 | 9.5±1.0 | 11.5±1.0 | 10,000 | - | |

| AR02 | 178.0±1.0 | 60.0+1.0 | 13.5±0.7 | 9.5±1.0 | 11.5±1.0 | 10,000 | - | |

| AR03 | 178.0±1.0 | 60.0+1.0 | 13.5±0.7 | 9.5±1.0 | 11.5±1.0 | 5,000 | - | |

| AR05 | 178.0±1.0 | 60.0+1.0 | 13.5±0.7 | 9.5±1.0 | 11.5±1.0 | 5,000 | - | |

| AR06 | 178.0±1.0 | 60.0+1.0 | 13.5±0.7 | 9.5±1.0 | 11.5±1.0 | 5,000 | - | |

| AR13 | 178.0±1.0 | 60.0±1.0 | 13.5±0.7 | 9.5±1.0 | 11.5±1.0 | 5,000 | - | |

| AR10 | 178.0±1.0 | 60.0+1.0 | 13.5±0.7 | 13.5±1.0 | 15.5±1.0 | - | 4,000 | |

| AR12 | 178.0±1.0 | 60.0+1.0 | 13.5±0.7 | 13.5±1.0 | 15.5±1.0 | - | 4,000 |

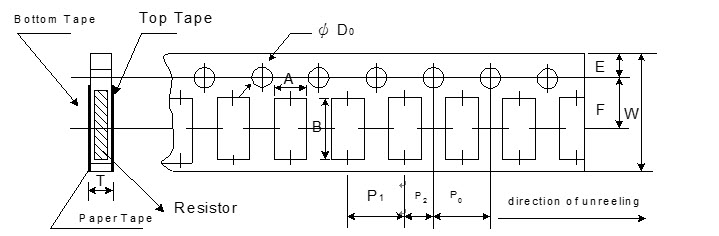

Paper Tape Specifications

| Type | A | B | W | E | F | P0 | P1 | P2 | ΦD0 | T |

|---|---|---|---|---|---|---|---|---|---|---|

| AR01 | 0.40±0.05 | 0.70±0.05 | 8.00±0.10 | 1.75±0.05 | 3.5±0.05 | 4.00±0.10 | 2.00±0.05 | 2.00±0.05 | 1.55±0.03 | 0.42±0.02 |

| AR02 | 0.70±0.05 | 1.16±0.05 | 8.00±0.10 | 1.75±0.05 | 3.5±0.05 | 4.00±0.10 | 2.00±0.05 | 2.00±0.05 | 1.55±0.05 | 0.40±0.03 |

| AR03 | 1.10±0.05 | 1.90±0.05 | 8.00±0.10 | 1.75±0.05 | 3.5±0.05 | 4.00±0.10 | 4.00±0.10 | 2.00±0.05 | 1.55±0.05 | 0.60±0.03 |

| AR05 | 1.60±0.05 | 2.37±0.05 | 8.00±0.10 | 1.75±0.05 | 3.5±0.05 | 4.00±0.10 | 4.00±0.10 | 2.00±0.05 | 1.55±0.05 | 0.75±0.05 |

| AR06 | 2.00±0.05 | 3.55±0.05 | 8.00±0.10 | 1.75±0.05 | 3.5±0.05 | 4.00±0.10 | 4.00±0.10 | 2.00±0.05 | 1.55±0.05 | 0.75±0.05 |

| AR13 | 2.75±0.05 | 3.40±0.05 | 8.00±0.10 | 1.75±0.05 | 3.5±0.05 | 4.00±0.05 | 4.00±0.10 | 2.00±0.05 | 1.60±0.10 | 0.75±0.05 |

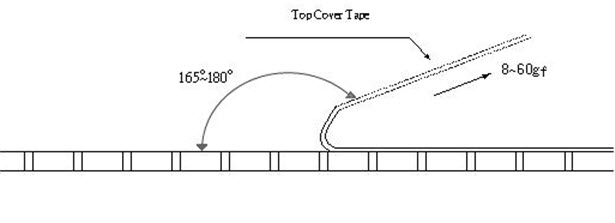

☑ Peel force of top cover tape

☑ The peel speed shall be about 300mm/min±5%

☑ The peel force of top cover tape shall be between 8gf to 60gf

Emboss Plastic Tape Specifications (Unit: mm)

| Type | A | B | W | E | F | P0 | P1 | P2 | ØD0 | T |

|---|---|---|---|---|---|---|---|---|---|---|

| AR10 | 2.85±0.10 | 5.45±0.10 | 12.0±0.10 | 1.75±0.10 | 5.5±0.05 | 4.00±0.05 | 4.00±0.10 | 2.00±0.05 | 1.50+0.10 | 1.00±0.20 |

| AR12 | 3.40±0.10 | 6.65±0.10 | 12.0±0.10 | 1.75±0.10 | 5.5±0.05 | 4.00±0.05 | 4.00±0.10 | 2.00±0.05 | 1.50+0.10 | 1.00±0.20 |

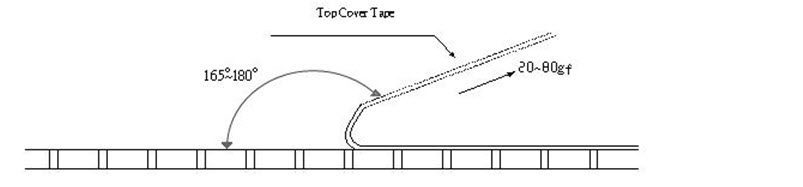

☑ Peel force of top cover tape

☑ The peel speed shall be about 300mm/min±5%

☑ The peel force of top cover tape shall be between 20gf to 80gf

Thin film Precision resistor 0.01%, TC2ppm, wirebondale, Anti-Crossive, MELF. Current sensing, Metal...

Read More

Ceramic high frequency chip inductors, small size to 01005. Thin film, multilayer, wirewound , ferrite...

Read More

Multilayer Ceramic capacitor offers high Voltage, high frequency, low noise, High Q, Low TCR. NPO, X7R,...

Read More