AUTOMOBILANWENDUNGEN

Dünnschicht-Präzisionswiderstand 0,01%, TC2ppm, Drahtbondable, Antikorrosiv, MELF. Stromsensoren, Metall,...

Weiterlesen

Niederohmiger (Metallstreifen-)Chipwiderstand in Automobilqualität – Serie LRP..A

LRP..A Series2512 ±0.5% 50 2W Series200Ω 4K/Reel

| Größe | Toleranz | TCR (ppm /℃) | Leistung | Widerstand (Ohm) | Verpackung |

|---|---|---|---|---|---|

| 2512 | ±0.5% | 50 | 2W | 200 | 4K/Reel |

| Item | Requirement | Test Method |

|---|---|---|

| Temperature Coefficient of Resistance (T.C.R.) |

As Spec. | IEC60115-1 4.8 JIS-C-5201-1 4.8 -55°C~+125°C, 25°C is the reference temperature |

| Short Time Overload | ±1.0% | IEC60115-1 4.13 JIS-C-5201-1 4.13 5*rated power for 5 seconds |

| Insulation Resistance | ³10G | IEC60115-1 4.6 JIS-C-5201-1 4.13 100V DC for 1 minute |

| Endurance | ±1.0% | IEC60115-1 4.25 JIS-C-5201-1 4.25.1 70±2°C, rated power for 1000 hrs with 1.5 hrs “ON” and 0.5 hr “OFF” |

| Biased Humidity | ±1.0% | MIL-STD-202 Method 103 1000 hrs 85°C/85%RH 10% of operating power |

| Dry Heat | ±1.0% | IEC60115-1 4.23.2 JIS-C-5201-1 4.23.2 at +170°C for 1000 hrs |

| Bending Strength | ±1.0% | JIS-C-5201-1 4.33 IEC-60115-1 4.33 Bending width 2mm once for 5 seconds |

| Solderability | 95% min. coverage | JIS-C-5201-1 4.17 IEC-60115-1 4.17 245±5°C for 3 seconds |

| Resistance to Soldering Heat | ±0.5% | JIS-C-5201-1 4.18 IEC-60115-1 4.18 260±5°C for 10 seconds |

| Rapid Change of Temperature | ±1.0% | JIS-C-5201-1 4.19 IEC-60115-1 4.19 -55°C to +155°C, 5 cycles |

| Low Temperature Storage | ±1.0% | IEC60115-1 4.23.4 JIS-C-5201-1 4.23.4 at -55°C for 2 hrs |

RCWV(Rated Continuous Working Voltage)= √(P*R) or Max. Operating Voltage whichever is lower.

☑ Storage Temperature: 15~28°C; Humidity < 80%RH

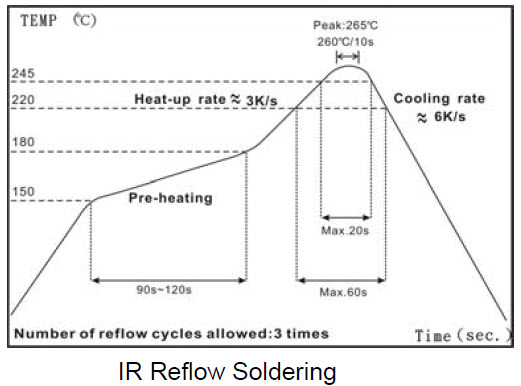

(Reflow soldering only)

(1) Time of IR reflow soldering at maximum temperature point 260°C:10s

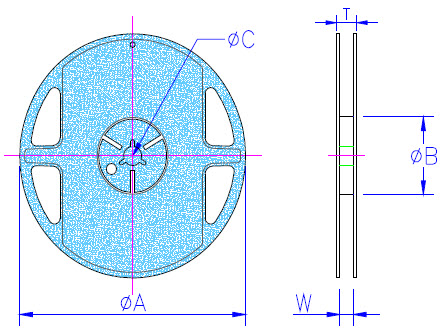

Packing Quantity & Reel Specifications

| Type | Resistance (mΩ) | Packaging Quantity | Tape Width | Reel Diameter | ΦA (mm) | ΦB (mm) | ΦC (mm) | W (mm) | T (mm) | |

|---|---|---|---|---|---|---|---|---|---|---|

| LRP06 | 8~20 | Paper | 5K | 8mm | 7 inch | 178.5±1.5 | 60+1/-0 | 13.0±0.2 | 9.0±0.5 | 12.5±0.5 |

| LRP 12 | 4~100 | Embossed | 4K | 12mm | 7 inch | 178.5±1.5 | 60±1.0 | 13.0±0.5 | 13.0±1.0 | 15.5±0.5 |

| LRP12 | 3 | Embossed | 2K | 12mm | 7 inch | 178.5±1.5 | 60±1.0 | 13.0±0.5 | 13.0±1.0 | 15.5±0.5 |

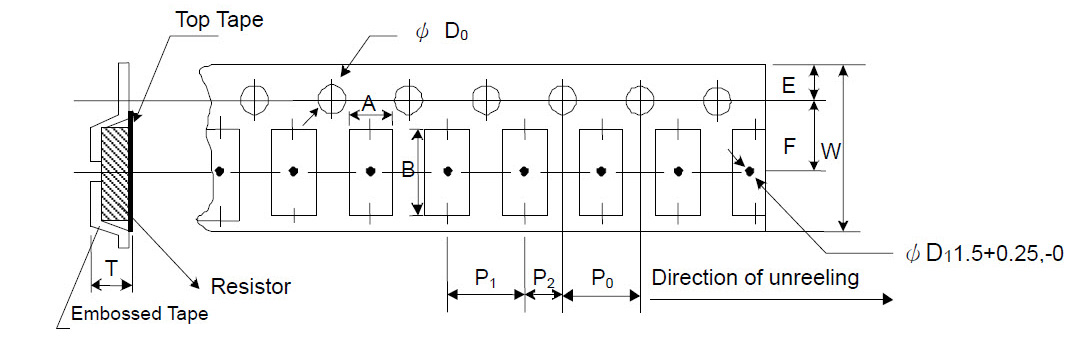

Embossed Plastic Tape Specifications

| Type | A (mm) | B (mm) | W (mm) | E (mm) | F (mm) | P0 (mm) | P1 (mm) | P2 (mm) | ΦD0 (mm) | T (mm) |

|---|---|---|---|---|---|---|---|---|---|---|

| LRP12 | 3.50±0.10 | 6.70±0.10 | 12.0±0.30 | 1.75±0.10 | 5.5±0.05 | 4.00±0.10 | 4.00±0.10 | 2.00±0.05 | 1.50+0.1, -0 | 1.20+0 |

| LRP12(3mΩ) | 3.50±0.10 | 6.70±0.10 | 12.0±0.30 | 1.75±0.10 | 5.5±0.05 | 4.00±0.10 | 4.00±0.10 | 2.00±0.05 | 1.50+0.1, -0 | 1.45±0.20 |

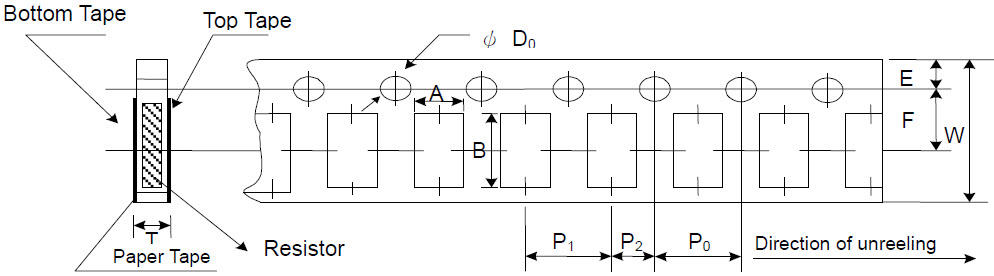

Paper Tape Specifications

| Type | A (mm) | B (mm) | W (mm) | E (mm) | F (mm) | P0 (mm) | P1 (mm) | P2 (mm) | ΦD0 (mm) | T (mm) |

|---|---|---|---|---|---|---|---|---|---|---|

| LRP06 | 1.90±0.10 | 3.50±0.20 | 8.0±0.20 | 1.75±0.10 | 3.50±0.05 | 4.00±0.10 | 4.00±0.05 | 2.00±0.05 | 1.50+0.1, -0 | 0.85±0.10 |

Dünnschicht-Präzisionswiderstand 0,01%, TC2ppm, Drahtbondable, Antikorrosiv, MELF. Stromsensoren, Metall,...

Weiterlesen

Keramische Hochfrequenz-Chip-Induktoren, klein bis 01005. Dünnschicht-, Mehrschicht-, Drahtgewickelte-,...

Weiterlesen

Mehrschicht-Keramikkondensator bietet hohe Spannung, hohe Frequenz, geringes Rauschen, hohe Güte, niedrige...

Weiterlesen