APPLICATIONS AUTOMOBILES

Résistance de précision en film mince 0,01 %, TC2ppm, wirebondale, anti-corrosion, MELF. Détection...

Lire la suite

Résistance à puce en métal à faible ohm pour la détection de courant - Série CSM

CSM Series0402 ±1% 300 1/4W Series3Ω 10K/Reel

| Taille | Tolérance | TCR (ppm /℃) | Puissance | Résistance (Ohm) | Emballage |

|---|---|---|---|---|---|

| 0402 | ±1% | 300 | 1/4W | 3 | 10K/Reel |

| Item Type | Power Rating at 70°C | Operating Temp. Range | Max. Overload Current | Resistance Range (mΩ) | TCR (PPM/°C) | |||

|---|---|---|---|---|---|---|---|---|

| ±0.5% | ±1% | ±2% | ±5% | |||||

| CSM02 (0402) | 1/4W | -55 ~ +175°C | 15.8A | – | 5 - 6 | ±300 | ||

| 13.4A | – | 7 - 9 | ±200 | |||||

| 11.2A | 30 – 50 | 10 - 50 | ±100 | |||||

| CSM03 (0603) | 1/2W | 22.7A | – | 5 - 6 | ±150 | |||

| 18.9A | – | 7 - 9 | ±100 | |||||

| 15.8A | 30 – 100 | 10 - 100 | ±100 | |||||

| CSM05 (0805) | 3/4W | 27.4A | – | 5 - 9 | ±100 | |||

| 19.4A | 30 – 100 | 10 - 100 | ±50 | |||||

| CSM06 (1206) | 1W | 31.6A | – | 5 - 9 | ±100 | |||

| 22.4A | 30 – 100 | 10 - 100 | ±50 | |||||

| CSM10 (2010) | 1.5W | 38.7A | – | 5 - 9 | ±100 | |||

| 27.4A | 30 – 100 | 10 - 100 | ±50 | |||||

| CSM12 (2512) | 2W | 40.0A | – | 5 - 9 | ±100 | |||

| 28.3A | 30 – 100 | 10 - 100 | ±50 | |||||

Operating Voltage=√(P*R) ; Overload Voltage=2.5*√(P*R) ; Operating Current=√(P/R)

☑ Viking is capable of manufacturing the optional spec based on customer's requirement.

For Standard Power Rating Series

| Item | Requirement | Test Method |

|---|---|---|

| Temperature Coefficient of Resistance (T.C.R.) | As Spec. | JIS-C-5201-1 4.8 IEC-60115-1 4.8 -55°C~+125°C, 25°C is the reference temperature |

| Short Time Overload | ±(0.5%+0.05Ω) | JIS-C-5201-1 4.13 IEC-60115-1 4.13 5 X Rated Power for 5 seconds |

| Insulation Resistance | ≧10G | JIS-C-5201-1 4.6 IEC-60115-1 4.6 Max. Overload Voltage for 1 minute |

| Endurance | ±(1.0%+0.05Ω) | JIS-C-5201-1 4.25 IEC-60115-1 4.25.1 70±2°C, RCWV for 1000 hrs with 1.5 hrs “ON” and 0.5 hr “OFF” |

| Damp Heat with Load | ±(1.0%+0.05Ω) | JIS-C-5201-1 4.24 IEC-60115-1 4.24 40±2°C, 90~95% R.H., RCWV for 1000 hrs with 1.5 hrs “ON” and 0.5 hr “OFF” |

| Dry Heat | ±(0.5%+0.05Ω) | JIS-C-5201-1 4.23 IEC-60115-1 4.23.2 at +155°C for 1000 hrs |

| Bending Strength | ±(1.0%+0.05Ω) | JIS-C-5201-1 4.33 IEC-60115-1 4.33 Bending once for 60 seconds 2010, 2512 sizes: 2mm Other sizes: 3mm |

| Solderability | 95% min. coverage | JIS-C-5201-1 4.17 IEC-60115-1 4.17 245±5°C for 3 seconds |

| Resistance to Soldering Heat | ±(0.5%+0.05Ω) | JIS-C-5201-1 4.18 IEC-60115-1 4.18 260±5°C for 10 seconds |

| Voltage Proof | No breakdown or flashover | JIS-C-5201-1 4.7 IEC-60115-1 4.7 1.42 times Max. Operating Voltage for 1 minute |

| Leaching | Individual leaching area ≦5% Total leaching area ≦10% | JIS-C-5201-1 4.18 IEC-60068-2-58 8.2.1 260±5°C for 30 seconds |

| Rapid Change of Temperature | ±(0.5%+0.05Ω) | JIS-C-5201-1 4.19 IEC-60115-1 4.19 -55°C to +155°C, 5 cycles |

RCWV(Rated Continuous Working Voltage)=√(P*R) or Max. Operating Voltage whichever is lower.

☑ Storage Temperature: 15~28°C; Humidity < 80%RH

For High Power Rating Series

| Item | Requirement | Test Method |

|---|---|---|

| Temperature Coefficient of Resistance (T.C.R.) | As Spec. | JIS-C-5201-1 4.8 IEC-60115-1 4.8 -55°C~+125°C, 25°C is the reference temperature |

| Short Time Overload | Δ R ≤±1%R | JIS-C-5201-1 4.13 IEC-60115-1 4.13 5 X Rated Power for 5 seconds. 2512 size:4*Rated Power for 5 seconds. Other size:5*Rated Power for 5 seconds. |

| Insulation Resistance | ≧1000MΩ | JIS-C-5201-1 4.6 IEC-60115-1 4.6 Max. Overload Voltage for 1 minute |

| Operational Life | Δ R ≦±1%R | MIL-STD-202 Method 108 Condition D steady state TA=125°C at derated power. Measurement at 24±4 hours after test conclusion |

| Biased Humidity | Δ R ≦±1%R | MIL-STD-202 Method 103 85°C / 85% R.H., 1000 hrs apply 10% of operating power(current) or limiting element current whichever is lower |

| High Temperature Exposure | Δ R ≦±1%R | MIL-STD-202 Method 108 at +155°C for 1000 hrs |

| Temperature Cycling | Δ R ≦±1%R | JESD22 Method JA-104 -55°C to +125°C, 1000 cycles |

| Bending Strength (Board Flex) | Δ R ≦±1%R | JIS-C-5201-1 4.33 Bending once for 60 seconds 0402~1206 sizes: 3mm |

| Solderability | 95% min. coverage | JIS-C-5201-1 4.17 IEC-60115-1 4.17 245±5°C for 3 seconds |

| Resistance to Soldering Heat | Δ R ≦±1%R | JIS-C-5201-1 4.18 IEC-60115-1 4.18 260±5°C for 10 seconds |

| Voltage Proof | No breakdown or flashover | JIS-C-5201-1 4.7 IEC-60115-1 4.7 1.42 times Max. Operating Voltage for 1 minute |

| Resistance to solvents | Marking Unsmeared | MIL-STD-202 Method 215 Add Aqueous wash chemical - OKEM Clean or equivalent. Do not use banned solvents |

| Mechanical Shock | Δ R ≦±1%R | MIL-STD-202 Method 213 Wave Form: Tolerance for half sine shock pulse. Peak value is 100g's. Normal duration (D) is 6. |

| Vibration | Δ R≦± 1%R | MIL-STD-202 Method 204 5 g's for 20 min., 12 cycles each of 3 orientations, 10-2000 Hz |

| ESD | Δ R≦± 1%R | AEC-Q200-002 Human body model 0402 Size: 1KV Other Sizes: 2KV |

| Flammability | No ignition of the tissue paper or scorching or the pinewood board | UL-94 V-0 or V-1 are acceptable. Electrical test not required. |

| Terminal strength | No broken | AEC-Q200-006 Force of 1.8kg for 60 seconds |

RCWV(Rated Continuous Working Voltage)=√(P*R) or Max. Operating Voltage whichever is lower.

☑ Storage Temperature: 15~28°C; Humidity < 80%RH

| Type | Code |

|---|---|

| 1R0 | 1.000Ω |

| R10 | 0.100Ω |

| R01 | 0.010Ω |

| 101 | 0.101Ω |

| 035 | 0.035Ω |

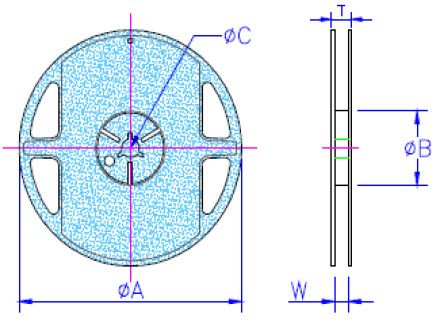

Packing Quantity & Reel Specifications

| Type | ΦA (mm) | ΦB (mm) | ΦC (mm) | W (mm) | T (mm) | Paper Tape (EA) | Emboss Plastic Tape (EA) |

|---|---|---|---|---|---|---|---|

| CSM02 | 178.0±1.0 | 60.0+1.0 | 13.5±0.7 | 9.5±0.1 | 11.5±1.0 | 10,000 | - |

| CSM03 | 178.0±1.0 | 60.0+1.0 | 13.5±0.7 | 9.5±0.1 | 11.5±1.0 | 5,000 | - |

| CSM05 | 178.0±1.0 | 60.0+1.0 | 13.5±0.7 | 9.5±0.1 | 11.5±1.0 | 5,000 | - |

| CSM06 | 178.0±1.0 | 60.0+1.0 | 13.5±0.7 | 9.5±0.1 | 11.5±1.0 | 5,000 | - |

| CSM10 | 178.0±1.0 | 60.0+1.0 | 13.5±0.7 | 13.5±1.0 | 15.5±1.0 | - | 4,000 |

| CSM12 | 178.0±1.0 | 60.0+1.0 | 13.5±0.7 | 13.5±1.0 | 15.5±1.0 | - | 4,000 |

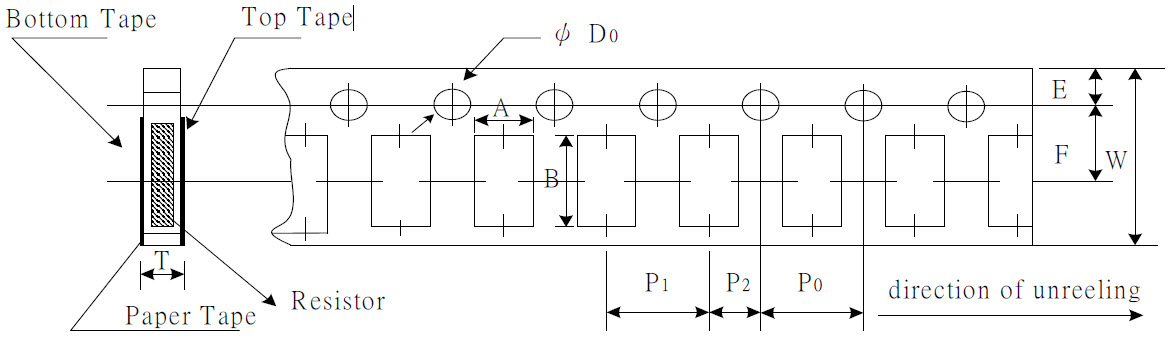

Paper Tape Specifications

| Type | A (mm) | B (mm) | W (mm) | E (mm) | F (mm) | P0 (mm) | P1 (mm) | P2 (mm) | ΦD0 (mm) | T (mm) |

|---|---|---|---|---|---|---|---|---|---|---|

| CSM02 | 0.66±0.06 | 1.18±0.06 | 8.0±0.20 | 1.75±0.10 | 3.50±0.05 | 4.00±0.10 | 2.00±0.05 | 2.00±0.05 | 1.50±0.05 | 0.60±0.06 |

| CSM03 | 1.10±0.10 | 1.90±0.10 | 8.0±0.20 | 1.75±0.10 | 3.50±0.05 | 4.00±0.10 | 4.00±0.05 | 2.00±0.05 | 1.50+0.1,-0 | 0.70±0.10 |

| CSM03 (1/2W) | 1.10±0.10 | 1.85±0.10 | 8.0±0.20 | 1.75±0.10 | 3.50±0.05 | 4.00±0.10 | 4.00±0.05 | 2.00±0.05 | 1.50+0.1,-0 | 0.95±0.05 |

| CSM05 | 1.60±0.10 | 2.40±0.20 | 8.0±0.20 | 1.75±0.10 | 3.50±0.05 | 4.00±0.10 | 4.00±0.05 | 2.00±0.05 | 1.50+0.1,-0 | 0.85±0.10 |

| CSM05 (3/4W) | 1.65±0.10 | 2.35±0.20 | 8.0±0.20 | 1.75±0.10 | 3.50±0.05 | 4.00±0.10 | 4.00±0.05 | 2.00±0.05 | 1.50+0.1,-0 | 0.95±0.05 |

| CSM06 | 1.90±0.10 | 3.50±0.20 | 8.0±0.20 | 1.75±0.10 | 3.50±0.05 | 4.00±0.10 | 4.00±0.05 | 2.00±0.05 | 1.50+0.1,-0 | 0.85±0.10 |

| CSM06 (1W) | 1.90±0.10 | 3.50±0.20 | 8.0±0.20 | 1.75±0.10 | 3.50±0.05 | 4.00±0.10 | 4.00±0.05 | 2.00±0.05 | 1.50+0.1,-0 | 0.95±0.05 |

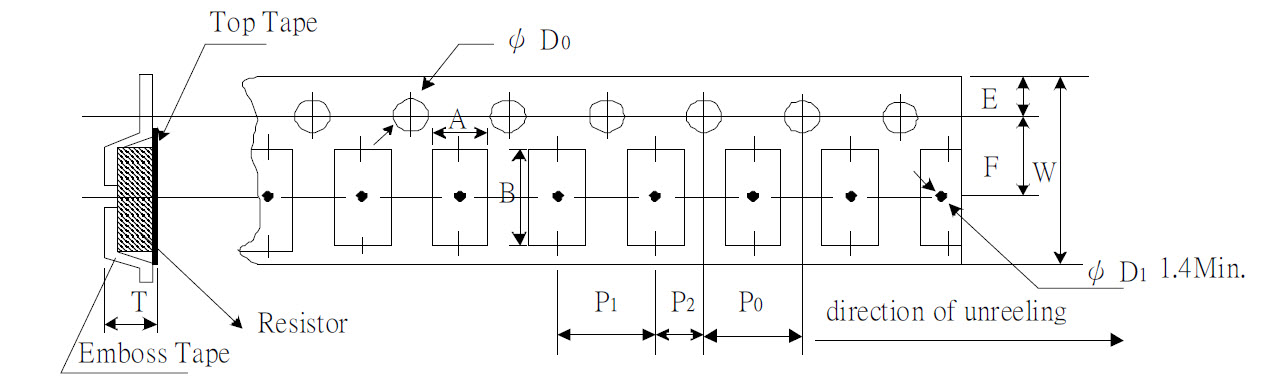

Emboss Plastic Tape Specifications

| Type | A (mm) | B (mm) | W (mm) | E (mm) | F (mm) | P0 (mm) | P1 (mm) | P2 (mm) | ΦD0 (mm) | T (mm) |

|---|---|---|---|---|---|---|---|---|---|---|

| CSM10 | 2.80±0.10 | 5.50±0.10 | 12.0±0.30 | 1.75±0.10 | 5.5±0.05 | 4.00±0.05 | 4.00±0.10 | 2.00±0.05 | 1.50+0.10 | 1.00±0.20 |

| CSM12 | 3.50±0.10 | 6.70±0.10 | 12.0±0.30 | 1.75±0.10 | 5.5±0.05 | 4.00±0.05 | 4.00±0.10 | 2.00±0.05 | 1.50+0.10 | 1.00±0.20 |

Résistance de précision en film mince 0,01 %, TC2ppm, wirebondale, anti-corrosion, MELF. Détection...

Lire la suite

Inducteurs céramiques haute fréquence, de petite taille jusqu'à 01005. Film mince, multicouche, bobiné,...

Lire la suite

Le condensateur céramique multicouche offre une haute tension, haute fréquence, faible bruit, haute...

Lire la suite