APPLICATIONS AUTOMOBILES

Résistance de précision en film mince 0,01 %, TC2ppm, wirebondale, anti-corrosion, MELF. Détection...

Lire la suiteRésistance à puce de précision à film mince - Série AR

ARBTC Series1210 ±1% 15 1/3W Series2.55KΩ 5K/Reel

| Taille | Tolérance | TCR (ppm /℃) | Puissance | Résistance (Ohm) | Emballage |

|---|---|---|---|---|---|

| 1210 | ±1% | 15 | 1/3W | 2.55K | 5K/Reel |

| Item | Power Rating at 70℃ | Operating Temp. Range | Max. Operating Voltage | Max. Overload Voltage | Resistance Range | TCR (PPM/℃) | |||||

| Type | ±0.01% | ±0.05% | ±0.1% | ±0.25% | ±0.5% | ±1% | |||||

| AR01 (0201) | 1/20W | -55 ~ +155℃ | 25V | 50V | - | 22Ω - 75KΩ | ±25 ±50 |

||||

| AR02 (0402) | 1/10W | -55 ~ +155℃ | 50V | 100V | 49.9Ω - 4.99KΩ | - | ±1 ±2 ±3 |

||||

| 49.9Ω - 20KΩ | ±5 | ||||||||||

| 49.9Ω - 12KΩ | 49.9Ω - 100KΩ | ±10 ±15 |

|||||||||

| - | 49.9Ω - 12KΩ | 4.7Ω~255KΩ | ±25 ±50 |

||||||||

| AR03 (0603) | 1/10W | -55 ~ +155℃ | 75V | 150V | 24.9Ω - 15KΩ | - | ±1 ±2 ±3 |

||||

| 24.9Ω - 60KΩ | ±5 | ||||||||||

| 24.9Ω - 100KΩ | 4.7Ω - 332KΩ | 4.7Ω - 511KΩ | ±10 ±15 |

||||||||

| 1Ω -1MΩ | ±25 ±50 |

||||||||||

| 1/6W | -55 ~ +155℃ | 100V | 150V | - | 10Ω - 332KΩ | ±25 ±50 |

|||||

| AR05 (0805) | 1/8W | -55 ~ +155℃ | 150V | 300V | 24.9Ω - 30KΩ | - | ±1 ±2 ±3 |

||||

| 24.9Ω - 150KΩ | ±5 | ||||||||||

| 24.9Ω - 200KΩ | 4.7Ω -511KΩ | 4.7Ω -1MΩ | ±10 ±15 |

||||||||

| 1Ω - 2MΩ | ±25 ±50 |

||||||||||

| 1/4W | -55 ~ +155℃ | 150V | 300V | - | 10Ω - 499KΩ | ±25 ±50 |

|||||

| AR06 (1206) | 1/4W | -55 ~ +155℃ | 200V | 400V | 24.9Ω - 49.9KΩ | - | ±1 ±2 ±3 |

||||

| 24.9Ω - 300KΩ | ±5 | ||||||||||

| 24.9Ω - 499KΩ | 4.7Ω - 1MΩ | ±10 ±15 |

|||||||||

| 1Ω - 2MΩ | ±25 ±50 |

||||||||||

| 1/3W | -55 ~ +155℃ | 200V | 400V | - | 10Ω ~1MΩ | ±25 ±50 |

|||||

| AR13 (1210) | 1/ 3W | -55 ~ +155℃ | 200V | 400V | 24.9Ω – 49.9KΩ | - | ±1 ±2 ±3 |

||||

| 24.9Ω – 300KΩ | ±5 | ||||||||||

| 24.9Ω - 499KΩ | 4.7Ω - 1MΩ | ±10 ±15 |

|||||||||

| 1Ω - 2MΩ | ±25 ±50 |

||||||||||

| AR10(2010) | 1/3W | -55 ~ +155℃ | 200V | 400V | 24.9Ω - 49.9KΩ | - | ±1 ±2 ±3 |

||||

| 24.9Ω - 300KΩ | ±5 | ||||||||||

| 24.9Ω - 499KΩ | 4.7Ω - 1MΩ | ±10 ±15 |

|||||||||

| 1Ω - 2MΩ | ±25 ±50 |

||||||||||

| 1/2W | -55 ~ +155℃ | 200V | 400V | 24.9Ω - 2KΩ | 4.7Ω – 1MΩ | 1Ω – 1MΩ | ±10 ±15 ±25 ±50 |

||||

| AR12(2512) | 3/4W | -55 ~ +155℃ | 200V | 400V | 24.9Ω - 2KΩ | 4.7Ω – 2KΩ | 1Ω – 2KΩ | ±10 ±15 ±25 ±50 |

|||

| 1W | -55 ~ +155℃ | 200V | 400V | 24.9Ω - 2KΩ | 4.7Ω – 1MΩ | 1Ω – 1MΩ | ±10 ±15 ±25 ±50 |

||||

Operating Voltage=√(P*R) or Max. operating voltage listed above, whichever is lower.

Overload Voltage=2.5*√(P*R) or Max. overload voltage listed above, whichever is lower.

☑ Viking is capable of manufacturing the optional spec based on customer's requirement.

(Lower Resistance:1~10Ω ; High Power Rating)

| Item | Requirement | Test Method | |

|---|---|---|---|

| Tol. ≦ 0.05% | Tol. > 0.05%/th> | ||

| Temperature Coefficient of Resistance (T.C.R.) | As Spec. | MIL-STD-202 Method 304 +25/-55/+25/+125/+25°C |

|

| Short Time Overload | ΔR±0.05% | ΔR±0.2% | JIS-C-5201-1 4.13 RCWV*2.5 or Max. overload voltage whichever is lower for 5 seconds |

| ΔR±0.2% for high power rating | |||

| Insulation Resistance | >9999 MΩ | MIL-STD-202 Method 302 Apply 100VDC for 1 minute |

|

| Endurance | ΔR±0.05% | ΔR±0.2% | MIL-STD-202 Method 108A 70±2°C, RCWV for 1000 hrs with 1.5 hrs “ON” and 0.5 hrs “OFF” |

| 0201: >7kΩ ΔR±0.5% ≦7kΩ ΔR±0.2% |

|||

| ΔR±0.5% for high power rating | |||

| Damp Heat with Load | ΔR±0.05% | ΔR±0.3% | MIL-STD-202 Method 103B 40±2°C, 90~95% R.H. RCWV for 1000 hrs with 1.5 hrs “ON” and 0.5 hrs “OFF” |

| ΔR±0.5% for high power rating | |||

| Bending Strength | ΔR±0.05% | ΔR±0.1% | JIS-C-5201-1 4.33 Bending once for 60 seconds 2010, 2512: 2mm other sizes: 3mm |

| Solderability | 95% min. coverage | MIL-STD-202 Method 208H 245±5°C for 3 seconds |

|

| Resistance to Soldering Heat | ΔR±0.05% | ΔR±0.1% | MIL-STD-202 Method 210E 260±5°C for 10 seconds |

| Dielectric Withstand Voltage | By Type | MIL-STD-202 Method 301 Max. overload voltage for 1 minute |

|

| Thermal Shock | ΔR±0.05% | ΔR±0.2% | MIL-STD-202 Method 107G -55°C ~150°C, 100 cycles |

| Low Temperature Operation | ΔR±0.05% | ΔR±0.2% | JIS-C-5201-1 4.36 1 hour, -65°C, followed by 45 minutes of RCWV |

| ΔR±0.5% for high power rating | |||

| High Temperature Exposure | ΔR±0.5% | MIL-STD-202 Method 108 at +155°C for 1000 hrs |

|

RCWV(Rated continuous working voltage)= √(P*R) or Max. Operating voltage whichever is lower

☑ Storage Temperature: 15~28°C; Humidity < 80%RH

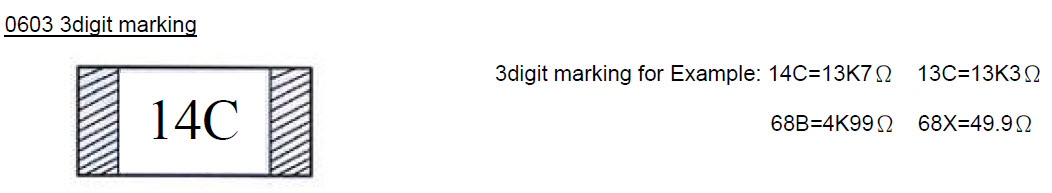

Marking Table

| Code | E96 | Code | E96 | Code | E96 | Code | E96 | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 01 | 100 | 25 | 178 | 49 | 316 | 73 | 562 | ||||

| 02 | 102 | 26 | 182 | 50 | 324 | 74 | 576 | ||||

| 03 | 105 | 27 | 187 | 51 | 332 | 75 | 590 | ||||

| 04 | 107 | 28 | 191 | 52 | 340 | 76 | 604 | ||||

| 05 | 110 | 29 | 196 | 53 | 348 | 77 | 619 | ||||

| 06 | 113 | 30 | 200 | 54 | 357 | 78 | 634 | ||||

| 07 | 115 | 31 | 205 | 55 | 365 | 79 | 649 | ||||

| 08 | 118 | 32 | 210 | 56 | 374 | 80 | 665 | ||||

| 09 | 121 | 33 | 215 | 57 | 383 | 81 | 681 | ||||

| 10 | 124 | 34 | 221 | 58 | 392 | 82 | 698 | ||||

| 11 | 127 | 35 | 226 | 59 | 402 | 83 | 715 | ||||

| 12 | 130 | 36 | 232 | 60 | 412 | 84 | 732 | ||||

| 13 | 133 | 37 | 237 | 61 | 422 | 85 | 750 | ||||

| 14 | 137 | 38 | 243 | 62 | 432 | 86 | 768 | ||||

| 15 | 140 | 39 | 249 | 63 | 442 | 87 | 787 | ||||

| 16 | 143 | 40 | 255 | 64 | 453 | 88 | 806 | ||||

| 17 | 147 | 41 | 261 | 65 | 464 | 89 | 825 | ||||

| 18 | 150 | 42 | 267 | 66 | 475 | 90 | 845 | ||||

| 19 | 154 | 43 | 274 | 67 | 487 | 91 | 866 | ||||

| 20 | 158 | 44 | 280 | 68 | 499 | 92 | 887 | ||||

| 21 | 162 | 45 | 287 | 69 | 511 | 93 | 909 | ||||

| 22 | 165 | 46 | 294 | 70 | 523 | 94 | 931 | ||||

| 23 | 169 | 47 | 301 | 71 | 536 | 95 | 953 | ||||

| 24 | 174 | 48 | 309 |

72 | 549 | 96 | 976 | ||||

| Code | A | B | C | D | E | F | G | H | X | Y | Z |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Multiplier | 10s0 | 101 | 102 | 103 | 104 | 105 | 106 | 107 | 10-1 | 10-2 | 10-3 |

0603 3digit marking for E24

Example: 101=100Ω 102=1KΩ

| E24 | 10 | 11 | 12 | 13 | 15 | 16 | 18 | 20 | 22 | 24 | 27 | 30 | 33 | 36 | 39 | 43 | 47 | 51 | 56 | 62 | 68 | 75 | 82 | 91 |

0805~2512 4digit marking

Example

| Resistance | 100Ω | 2.2KΩ | 10KΩ | 49.9KΩ | 100KΩ |

|---|---|---|---|---|---|

| marking | 1000 | 2201 | 1002 | 4992 | 1003 |

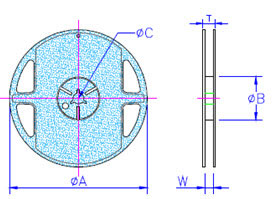

Packing Quantity & Reel Specifications (Unit :mm)

| Type | ØA | ØB | ØC | W | T | Paper Type(EA) | Emboss Plastic Tape(EA) |  |

|---|---|---|---|---|---|---|---|---|

| AR01 | 178.0±1.0 | 60.0+1.0 | 13.5±0.7 | 9.5±1.0 | 11.5±1.0 | 10,000 | - | |

| AR02 | 178.0±1.0 | 60.0+1.0 | 13.5±0.7 | 9.5±1.0 | 11.5±1.0 | 10,000 | - | |

| AR03 | 178.0±1.0 | 60.0+1.0 | 13.5±0.7 | 9.5±1.0 | 11.5±1.0 | 5,000 | - | |

| AR05 | 178.0±1.0 | 60.0+1.0 | 13.5±0.7 | 9.5±1.0 | 11.5±1.0 | 5,000 | - | |

| AR06 | 178.0±1.0 | 60.0+1.0 | 13.5±0.7 | 9.5±1.0 | 11.5±1.0 | 5,000 | - | |

| AR13 | 178.0±1.0 | 60.0±1.0 | 13.5±0.7 | 9.5±1.0 | 11.5±1.0 | 5,000 | - | |

| AR10 | 178.0±1.0 | 60.0+1.0 | 13.5±0.7 | 13.5±1.0 | 15.5±1.0 | - | 4,000 | |

| AR12 | 178.0±1.0 | 60.0+1.0 | 13.5±0.7 | 13.5±1.0 | 15.5±1.0 | - | 4,000 |

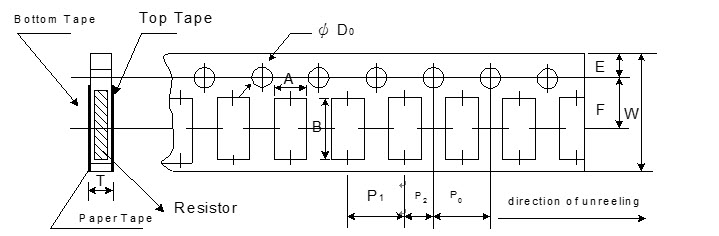

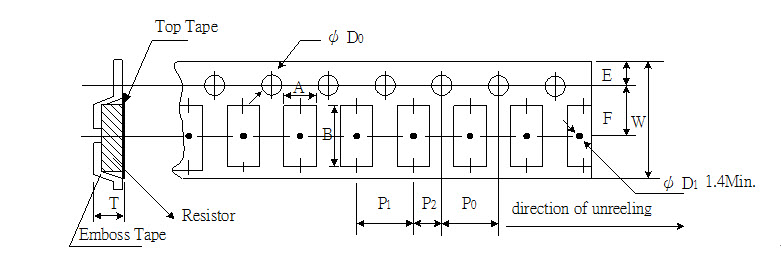

Paper Tape Specifications

| Type | A | B | W | E | F | P0 | P1 | P2 | ΦD0 | T |

|---|---|---|---|---|---|---|---|---|---|---|

| AR01 | 0.40±0.05 | 0.70±0.05 | 8.00±0.10 | 1.75±0.05 | 3.5±0.05 | 4.00±0.10 | 2.00±0.05 | 2.00±0.05 | 1.55±0.03 | 0.42±0.02 |

| AR02 | 0.70±0.05 | 1.16±0.05 | 8.00±0.10 | 1.75±0.05 | 3.5±0.05 | 4.00±0.10 | 2.00±0.05 | 2.00±0.05 | 1.55±0.05 | 0.40±0.03 |

| AR03 | 1.10±0.05 | 1.90±0.05 | 8.00±0.10 | 1.75±0.05 | 3.5±0.05 | 4.00±0.10 | 4.00±0.10 | 2.00±0.05 | 1.55±0.05 | 0.60±0.03 |

| AR05 | 1.60±0.05 | 2.37±0.05 | 8.00±0.10 | 1.75±0.05 | 3.5±0.05 | 4.00±0.10 | 4.00±0.10 | 2.00±0.05 | 1.55±0.05 | 0.75±0.05 |

| AR06 | 2.00±0.05 | 3.55±0.05 | 8.00±0.10 | 1.75±0.05 | 3.5±0.05 | 4.00±0.10 | 4.00±0.10 | 2.00±0.05 | 1.55±0.05 | 0.75±0.05 |

| AR13 | 2.75±0.05 | 3.40±0.05 | 8.00±0.10 | 1.75±0.05 | 3.5±0.05 | 4.00±0.05 | 4.00±0.10 | 2.00±0.05 | 1.60±0.10 | 0.75±0.05 |

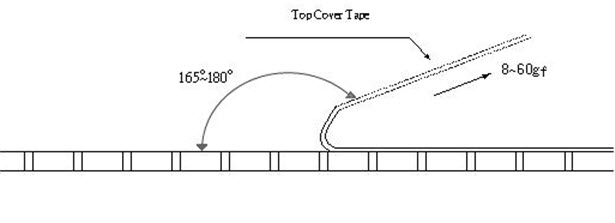

☑ Peel force of top cover tape

☑ The peel speed shall be about 300mm/min±5%

☑ The peel force of top cover tape shall be between 8gf to 60gf

Emboss Plastic Tape Specifications (Unit: mm)

| Type | A | B | W | E | F | P0 | P1 | P2 | ØD0 | T |

|---|---|---|---|---|---|---|---|---|---|---|

| AR10 | 2.85±0.10 | 5.45±0.10 | 12.0±0.10 | 1.75±0.10 | 5.5±0.05 | 4.00±0.05 | 4.00±0.10 | 2.00±0.05 | 1.50+0.10 | 1.00±0.20 |

| AR12 | 3.40±0.10 | 6.65±0.10 | 12.0±0.10 | 1.75±0.10 | 5.5±0.05 | 4.00±0.05 | 4.00±0.10 | 2.00±0.05 | 1.50+0.10 | 1.00±0.20 |

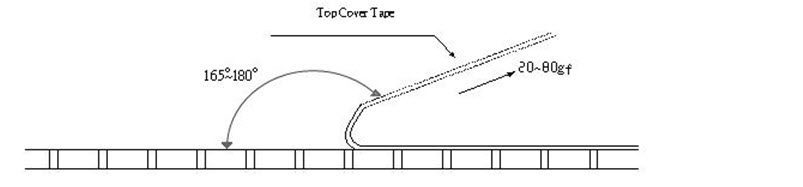

☑ Peel force of top cover tape

☑ The peel speed shall be about 300mm/min±5%

☑ The peel force of top cover tape shall be between 20gf to 80gf

Résistance de précision en film mince 0,01 %, TC2ppm, wirebondale, anti-corrosion, MELF. Détection...

Lire la suite

Inducteurs céramiques haute fréquence, de petite taille jusqu'à 01005. Film mince, multicouche, bobiné,...

Lire la suite

Le condensateur céramique multicouche offre une haute tension, haute fréquence, faible bruit, haute...

Lire la suite