칩 공통 모드 초크 (CM 시리즈 CMH06MT261)

CMH06MT261

칩 공통 모드 필터는 페라이트 코어와 두 개의 선 유형으로 감겨진 작은 칩 인덕터입니다. 노이즈 밴드에서 높은 공통 모드 임피던스로 노이즈 억제가 매우 효과적이며, 신호 밴드에서 낮은 차동 모드 임피던스, 높은 커플링 계수로 낮은 차동 모드 임피던스를 가지고 있습니다. 고속 신호에서 거의 왜곡이 없습니다. 일반적으로 모든 전자 기기의 EMI 방사 노이즈 억제에 사용됩니다.

CM Series1206 ±20% 260μH 0.5 Ω 310mA 125V 10MΩ min.

| 크기 | 허용오차 | 인덕턴스 | 테스트 조건 | DCR (Ω) 최대. | IDC (mA) | 정격 전압 | 내전압 Vdc (V) | 절연 저항 (MΩ) 최소. |

|---|---|---|---|---|---|---|---|---|

| 1206 | ±20% | 260 | 100MHz | 0.5 | 310 | 50 | 125 | 10 |

환경 특성

Electrical Performance Test

| Items | Requirement | Test Conditions / Test Methods |

|---|---|---|

| Impedance | Refer to standard electrical characteristic spec. Component should not be damaged | LCR Meter HP 4291B |

| DC Resistance DCR | Micro-Ohm meter (GOM-801G) | |

| Withstand Voltage (VDC) | Test Voltage: 2.5 Times Rated Voltage Testing Time: 60 seconds Charge Current: 0.5mA | |

| Rated Voltage (VDC) | Test Voltage: Rated Voltage Testing Time: 1 to 5 seconds Charge Current: 1mA | |

| Insulation Resistance (I.R) | Charge Current: 1minute 10M ohm min. |

Mechanical Performance Test

| Items | Requirement | Test Conditions / Test Methods |

|---|---|---|

| Component Adhesion (Push Test) | Base: 0805≧2 Lbs Cover: 0805≧1 Lbs Base: 1206≧4 Lbs Cover: 1206≧2 Lbs | The component should be soldered (232°C± 5°C for 10 sec.) to tinned copper substrate Applied force gauge to the side of component It must withstand force of 2 or 4 pounds without failure of the component. |

| Drop | Component should not be damaged | Dropping chip by each side and corner. Drop 10 times in total Drop height: 100 cm Drop weight: 125 g |

| Solderability | The terminal should at least be 90% covered with solder | The component shall be dipped in a melted solder bath at 245 ±5℃ for 3 seconds |

| Vibration Test (Low Frequency) | Component should not be damaged | 1. Amplitude: 1.5 m/m 2. Frequency: 10-55-10Hz (1min.) 3. Direction: X, Y, Z 4. Duration: 2 Hrs/X, Y, Z |

Climatic Test

| Items | Requirement | Test Conditions / Test Methods |

|---|---|---|

| Low Temperature Storage | Impedance change: Within± 20% Without distinct damage in appearance | 1. Temp: -40 ±2°C 2. Time: 1000±48 Hours 3. Component should be tested after 1hour at room temperature |

| Thermal Shock |  Total: 5 Cycles | |

| High Temperature Storage | 1. Temp: 85 ± 2°C 2. Time: 1000 ± 48 Hours 3. Component should be tested after 1hour at room temperature | |

| Humidity | 1. Temp: 40 ± 2°C 2. R.H. : 90 ~ 95% 3. Time: 48 ±2 Hours | |

| High Temperature Load Life | There should be no evidence of short or open circuit | 1. Temp: 85 ± 2°C 2. Time: 96 ± 12 Hours 3. Load: Allowed DC Current |

| Low Temperature Load Life | 1. Temp: -40 ± 2°C 2. Time: 96 ± 12 Hours 3. Load: Allowed DC Current |

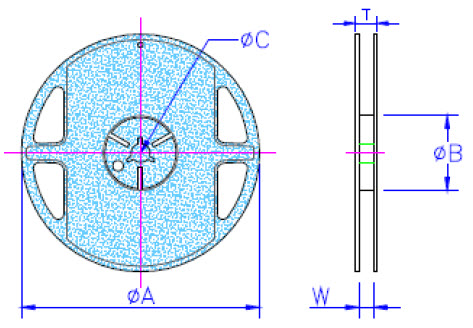

포장

Packaging Quantity & Reel Specifications

| Type | ΦA | ΦB | ΦC | W | T | Quantity (EA) |

|---|---|---|---|---|---|---|

| CMH05 | 178±2.0 | 60±0.5 | 13±0.3 | 9±0.3 | 11.4±1.0 | 2000 |

| CMH06 | 178±2.0 | 60±0.5 | 13±0.3 | 9±0.3 | 11.4±1.0 | 2000 |

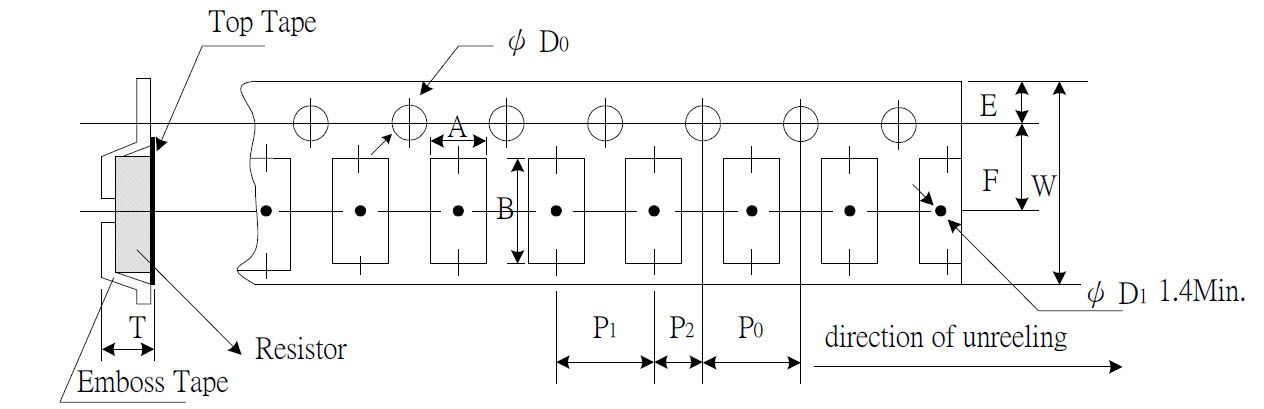

Embossed Plastic Tape Specifications

| Type | A (mm) | B (mm) | W (mm) | E (mm) | F (mm) | P0 (mm) | P1 (mm) | P2 (mm) | ΦD0 (mm) | T (mm) |

|---|---|---|---|---|---|---|---|---|---|---|

| CMH05 | 1.40±0.10 | 2.55±0.05 | 8.0±0.20 | 1.75±0.10 | 3.5±0.10 | 4.00±0.10 | 4.00±0.10 | 2.00±0.10 | 1.50+0.10 | 1.35±0.10 |

| CMH06 | 1.90±0.10 | 3.50±0.05 | 8.0±0.20 | 1.75±0.10 | 3.5±0.10 | 4.00±0.10 | 4.00±0.10 | 2.00±0.10 | 1.50+0.10 | 2.10±0.10 |

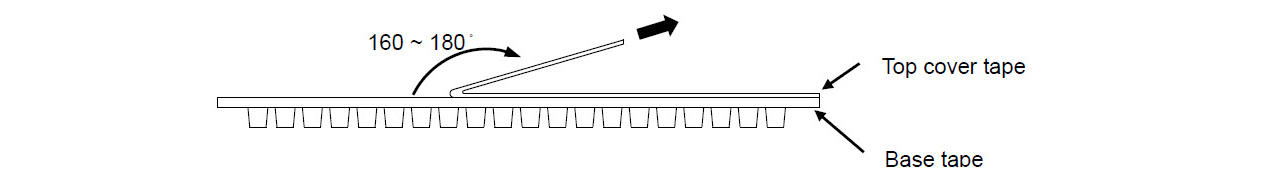

Peel-off Force

The force for tearing off cover tape is 0.05~0.69 (N) in the arrow direction at the following conditions:

Temperature: 5 ~ 35°C

Humidity: 45 ~ 85%

Atmospheric pressure: 860 ~ 1060hpa

주요 제품