AUTOMOTIVE APPLICATIONS

Thin film Precision resistor 0.01%, TC2ppm, wirebondale, Anti-Crossive, MELF. Current sensing, Metal...

Read MoreWire wound ceramic chip inductor, high frequency, RF inductor for high SRF, Excellent Q , superior temperarture tability. Stable inductance in hihg frequency circuit. High stable design for critical needs.

WL Series0402 ±5% 9nHμH 0.104 Ω 680mA 22 4.16GHz

| Size | Tolerance | Inductance | Test Condition | DCR (Ω) max. | IDC (mA) | Q | SRF |

|---|---|---|---|---|---|---|---|

| 0402 | ±5% | 9nH | 250MHz | 0.104 | 680 | 22 | 4.16GHz |

WL03(H) Wire Wound Chip Inductors / High Current Type

| Inductance (nH) | Tolerance | L Freq. (MHz) | Quality Factor min. | SRF (GHz) min. | DCR (Ω) max. | IDC (mA) max. |

|---|---|---|---|---|---|---|

| 1.6 | ± 5, ± 10% | 250 | 24 | 12.50 | 0.030 | 2400 |

| 3.6 | ± 5, ± 10% | 250 | 24 | 5.90 | 0.048 | 2300 |

| 3.9 | ± 5, ± 10% | 250 | 25 | 5.90 | 0.054 | 2200 |

| 6.8 | ± 5, ± 10% | 250 | 35 | 5.80 | 0.054 | 2100 |

| 7.5 | ± 5, ± 10% | 250 | 38 | 3.70 | 0.059 | 2100 |

| 8.2 | ± 5, ± 10% | 250 | 38 | 3.70 | 0.060 | 2000 |

| 10 | ± 2, ± 5, ± 10% | 250 | 38 | 3.70 | 0.071 | 2000 |

| 12 | ± 2, ± 5, ± 10% | 250 | 38 | 3.00 | 0.075 | 2000 |

| 15 | ± 2, ± 5, ± 10% | 250 | 38 | 2.80 | 0.080 | 1900 |

| 18 | ± 2, ± 5, ± 10% | 250 | 40 | 2.80 | 0.099 | 1900 |

| 22 | ± 2, ± 5, ± 10% | 250 | 42 | 2.40 | 0.099 | 1800 |

| 24 | ± 2, ± 5, ± 10% | 250 | 42 | 2.40 | 0.105 | 1800 |

WL02(H) Wire Wound Chip Inductors / High Q Type

| Inductance (nH) | Tolerance | L Freq. (MHz) | Quality Factor | SRF (GHz) min. | DCR (Ω) max. | IDC (mA) max. | |

|---|---|---|---|---|---|---|---|

| 900MHz | 1.7GHz | ||||||

| 1.0 | ± 0.2nH, ± 0.5nH, ± 5%, ± 10% | 250 | 46 | 75 | 16.0 | 0.030 | 2300 |

| 2.0 | ± 0.2nH, ± 0.5nH, ± 5%, ± 10% | 250 | 58 | 85 | 15.2 | 0.038 | 2100 |

| 2.2 | ± 0.2nH, ± 0.5nH, ± 5%, ± 10% | 250 | 60 | 86 | 15.1 | 0.038 | 2100 |

| 2.4 | ± 0.2nH, ± 0.5nH, ± 5%, ± 10% | 250 | 60 | 83 | 14.0 | 0.042 | 2000 |

| 2.7 | ± 0.2nH, ± 0.5nH, ± 5%, ± 10% | 250 | 62 | 85 | 13.0 | 0.075 | 1500 |

| 3.3 | ± 0.2nH, ± 0.5nH, ± 5%, ± 10% | 250 | 66 | 95 | 12.8 | 0.045 | 1700 |

| 3.6 | ± 0.2nH, ± 0.5nH, ± 5%, ± 10% | 250 | 65 | 94 | 11.7 | 0.045 | 1700 |

| 3.9 | ± 0.2nH, ± 0.5nH, ± 5%, ± 10% | 250 | 64 | 98 | 9.50 | 0.045 | 1700 |

| 4.3 | ± 0.5nH, ± 5%, ± 10% | 250 | 63 | 90 | 7.15 | 0.050 | 1600 |

| 4.7 | ± 0.5nH, ± 5%, ± 10% | 250 | 58 | 83 | 6.85 | 0.070 | 1500 |

| 5.1 | ± 2%, ± 5%, ± 10% | 250 | 54 | 76 | 6.80 | 0.115 | 1200 |

| 5.6 | ± 2%, ± 5%, ± 10% | 250 | 73 | 105 | 6.50 | 0.050 | 1600 |

| 6.2 | ± 2%, ± 5%, ± 10% | 250 | 73 | 100 | 5.80 | 0.055 | 1600 |

| 6.8 | ± 2%, ± 5%, ± 10% | 250 | 68 | 94 | 5.80 | 0.065 | 1500 |

| 7.5 | ± 2%, ± 5%, ± 10% | 250 | 60 | 82 | 5.40 | 0.090 | 1400 |

| 8.2 | ± 2%, ± 5%, ± 10% | 250 | 68 | 95 | 5.40 | 0.065 | 1500 |

| 8.7 | ± 2%, ± 5%, ± 10% | 250 | 68 | 95 | 5.00 | 0.065 | 1500 |

| 9.0 | ± 2%, ± 5%, ± 10% | 250 | 67 | 92 | 5.00 | 0.080 | 1400 |

| 9.5 | ± 2%, ± 5%, ± 10% | 250 | 64 | 90 | 4.70 | 0.090 | 1400 |

| 10 | ± 2%, ± 5%, ± 10% | 250 | 62 | 90 | 4.70 | 0.100 | 1300 |

| 11 | ± 2%, ± 5%, ± 10% | 250 | 68 | 98 | 4.70 | 0.065 | 1400 |

| 12 | ± 2%, ± 5%, ± 10% | 250 | 66 | 100 | 4.40 | 0.100 | 1200 |

| 13 | ± 2%, ± 5%, ± 10% | 250 | 62 | 82 | 4.20 | 0.150 | 870 |

| 15 | ± 2%, ± 5%, ± 10% | 250 | 62 | 85 | 3.90 | 0.110 | 1100 |

| 16 | ± 2%, ± 5%, ± 10% | 250 | 57 | 77 | 3.70 | 0.140 | 850 |

| 18 | ± 2%, ± 5%, ± 10% | 250 | 58 | 74 | 3.55 | 0.120 | 900 |

| 19 | ± 2%, ± 5%, ± 10% | 250 | 61 | 88 | 3.50 | 0.145 | 850 |

| 20 | ± 2%, ± 5%, ± 10% | 250 | 58 | 76 | 3.50 | 0.185 | 780 |

| 21 | ± 2%, ± 5%, ± 10% | 250 | 48 | 62 | 1.70 | 0.460 | 450 |

| 22 | ± 2%, ± 5%, ± 10% | 250 | 60 | 74 | 3.30 | 0.160 | 800 |

| 23 | ± 2%, ± 5%, ± 10% | 250 | 60 | 77 | 3.30 | 0.160 | 800 |

| 24 | ± 2%, ± 5%, ± 10% | 250 | 55 | 71 | 3.15 | 0.200 | 700 |

| 25 | ± 2%, ± 5%, ± 10% | 250 | 57 | 73 | 3.15 | 0.250 | 600 |

| 26 | ± 2%, ± 5%, ± 10% | 250 | 56 | 74 | 3.15 | 0.285 | 450 |

| 27 | ± 2%, ± 5%, ± 10% | 250 | 62 | 86 | 3.20 | 0.320 | 450 |

| 30 | ± 2%, ± 5%, ± 10% | 250 | 61 | 87 | 2.90 | 0.330 | 450 |

| 33 | ± 2%, ± 5%, ± 10% | 250 | 61 | 80 | 2.80 | 0.330 | 490 |

| 36 | ± 2%, ± 5%, ± 10% | 250 | 59 | 76 | 2.80 | 0.380 | 480 |

| 37 | ± 2%, ± 5%, ± 10% | 250 | 57 | 72 | 2.70 | 0.460 | 470 |

| 39 | ± 2%, ± 5%, ± 10% | 250 | 56 | 84 | 2.60 | 0.430 | 450 |

| 40 | ± 2%, ± 5%, ± 10% | 250 | 56 | 75 | 2.60 | 0.430 | 450 |

| 43 | ± 2%, ± 5%, ± 10% | 250 | 52 | 68 | 2.50 | 0.520 | 450 |

| 47 | ± 2%, ± 5%, ± 10% | 250 | 48 | 62 | 2.40 | 0.580 | 420 |

| 51 | ± 2%, ± 5%, ± 10% | 250 | 52 | 59 | 2.30 | 0.700 | 360 |

WL03(Q) Wire Wound Chip Inductors / High Q Type

| Inductance (nH) | Tolerance | L Freq. (MHz) | Q Typ at 250(MHz) | SRF Typ (GHz) | DCR (Ω) max. | IDC (mA) max. | 900MHz | 1.7GHz | ||

|---|---|---|---|---|---|---|---|---|---|---|

| L Typ | Q Typ | L Typ | Q Typ | |||||||

| 1.8 | ± 5, ± 10% | 250 | 23 | 16.0 | 0.033 | 2100 | 1.77 | 40 | 1.77 | 65 |

| 2.2 | ± 5, ± 10% | 250 | 13 | 15.0 | 0.180 | 900 | 2.14 | 25 | 2.12 | 35 |

| 3.0 | ± 5, ± 10% | 250 | 35 | 9.50 | 0.024 | 1000 | 2.96 | 65 | 2.97 | 85 |

| 3.3 | ± 5, ± 10% | 250 | 32 | 9.60 | 0.024 | 1900 | 3.28 | 67 | 3.32 | 104 |

| 3.6 | ± 2, ± 5, ± 10% | 250 | 40 | 9.70 | 0.031 | 1900 | 3.59 | 70 | 3.62 | 116 |

| 3.9 | ± 2, ± 5, ± 10% | 250 | 35 | 7.50 | 0.039 | 1600 | 3.88 | 68 | 3.95 | 108 |

| 4.3 | ± 2, ± 5, ± 10% | 250 | 30 | 7.50 | 0.080 | 1300 | 4.29 | 58 | 4.31 | 91 |

| 4.7 | ± 2, ± 5, ± 10% | 250 | 26 | 7.90 | 0.100 | 1100 | 4.65 | 48 | 4.71 | 75 |

| 5.1 | ± 2, ± 5, ± 10% | 250 | 40 | 8.90 | 0.036 | 1700 | 5.08 | 84 | 5.12 | 140 |

| 5.6 | ± 2, ± 5, ± 10% | 250 | 48 | 6.60 | 0.036 | 1700 | 5.6 | 87 | 5.73 | 456 |

| 6.0 | ± 2, ± 5, ± 10% | 250 | 49 | 6.00 | 0.036 | 1700 | 5.92 | 94 | 6.12 | 154 |

| 6.8 | ± 2, ± 5, ± 10% | 250 | 42 | 5.80 | 0.042 | 1400 | 6.83 | 88 | 7.05 | 143 |

| 7.2 | ± 2, ± 5, ± 10% | 250 | 48 | 5.40 | 0.052 | 1400 | 7.25 | 96 | 7.38 | 139 |

| 7.5 | ± 2, ± 5, ± 10% | 250 | 41 | 5.30 | 0.080 | 1300 | 7.55 | 81 | 7.85 | 12 |

| 8.2 | ± 2, ± 5, ± 10% | 250 | 46 | 5.90 | 0.054 | 1400 | 8.21 | 96 | 8.39 | 148 |

| 8.7 | ± 2, ± 5, ± 10% | 250 | 46 | 5.50 | 0.054 | 1400 | 8.73 | 97 | 9.00 | 149 |

| 9.1 | ± 2, ± 5, ± 10% | 250 | 40 | 5.10 | 0.037 | 1400 | 9.18 | 76 | 9.64 | 109 |

| 9.5 | ± 2, ± 5, ± 10% | 250 | 49 | 4.90 | 0.053 | 1400 | 9.56 | 98 | 9.99 | 149 |

| 10 | ± 2, ± 5, ± 10% | 250 | 49 | 4.30 | 0.048 | 1400 | 10.16 | 90 | 10.64 | 142 |

| 11 | ± 2, ± 5, ± 10% | 250 | 41 | 4.10 | 0.058 | 1400 | 11.06 | 78 | 11.82 | 108 |

| 12 | ± 2, ± 5, ± 10% | 250 | 37 | 4.10 | 0.088 | 1100 | 12.26 | 69 | 13.2 | 91 |

| 15 | ± 2, ± 5, ± 10% | 250 | 48 | 3.60 | 0.078 | 1200 | 15.41 | 83 | 17.2 | 124 |

| 16 | ± 2, ± 5, ± 10% | 250 | 45 | 3.50 | 0.085 | 1100 | 16.37 | 77 | 18.7 | 116 |

| 18 | ± 2, ± 5, ± 10% | 250 | 41 | 3.30 | 0.066 | 1200 | 18.56 | 76 | 20.9 | 100 |

| 22 | ± 2, ± 5, ± 10% | 250 | 44 | 3.15 | 0.140 | 850 | 22.7 | 77 | 25.9 | 88 |

| 23 | ± 2, ± 5, ± 10% | 250 | 40 | 3.00 | 0.183 | 850 | 24 | 69 | 29.53 | 80 |

| 24 | ± 2, ± 5, ± 10% | 250 | 42 | 2.95 | 0.074 | 1100 | 24.9 | 77 | 28.9 | 91 |

| 27 | ± 2, ± 5, ± 10% | 250 | 44 | 2.80 | 0.150 | 780 | 28.4 | 74 | 34.0 | 84 |

| 30 | ± 2, ± 5, ± 10% | 250 | 49 | 2.80 | 0.130 | 920 | 31.5 | 82 | 37.9 | 82 |

| 33 | ± 2, ± 5, ± 10% | 250 | 45 | 2.70 | 0.170 | 680 | 34.9 | 76 | 42.9 | 80 |

| 36 | ± 2, ± 5, ± 10% | 250 | 44 | 2.50 | 0.225 | 720 | 38.5 | 69 | 50.0 | 64 |

| 39 | ± 2, ± 5, ± 10% | 250 | 48 | 2.45 | 0.19 | 680 | 41.5 | 78 | 51.9 | 74 |

| 43 | ± 2, ± 5, ± 10% | 250 | 45 | 2.45 | 0.17 | 810 | 45.7 | 83 | 58.1 | 76 |

| 47 | ± 2, ± 5, ± 10% | 200 | 47 | 2.30 | 0.24 | 680 | 50.6 | 77 | 66.9 | 72 |

| 51 | ± 2, ± 5, ± 10% | 200 | 49 | 2.30 | 0.28 | 660 | 54.6 | 73 | 71.3 | 62 |

| 56 | ± 2, ± 5, ± 10% | 200 | 50 | 2.20 | 0.30 | 610 | 60.3 | 74 | 79.9 | 56 |

| 68 | ± 2, ± 5, ± 10% | 200 | 46 | 2.00 | 0.33 | 600 | 75.5 | 73 | 113.3 | 49 |

| 72 | ± 2, ± 5, ± 10% | 150 | 46 | 1.90 | 0.42 | 550 | 80.8 | 69 | - | - |

| 75 | ± 2, ± 5, ± 10% | 150 | 46 | 1.90 | 0.52 | 500 | 84.6 | 71 | - | - |

| 82 | ± 2, ± 5, ± 10% | 150 | 45 | 1.80 | 0.46 | 510 | 94 | 62 | - | - |

| 91 | ± 2, ± 5, ± 10% | 150 | 45 | 1.65 | 0.58 | 440 | 103 | 64 | - | - |

| 100 | ± 2, ± 5, ± 10% | 150 | 49 | 1.70 | 0.54 | 470 | 114 | 69 | - | - |

| 110 | ± 2, ± 5, ± 10% | 150 | 47 | 1.60 | 0.58 | 440 | 126.2 | 63 | - | - |

| 120 | ± 2, ± 5, ± 10% | 150 | 47 | 1.55 | 0.72 | 420 | 142.4 | 61 | - | - |

| 150 | ± 2, ± 5, ± 10% | 150 | 47 | 1.35 | 0.82 | 390 | 188.8 | 57 | - | - |

| 180 | ± 2, ± 5, ± 10% | 100 | 48 | 1.30 | 1.50 | 310 | 232.2 | 50 | - | - |

| 200 | ± 2, ± 5, ± 10% | 100 | 47 | 1.25 | 2.00 | 280 | 265 | 47 | - | - |

| 210 | ± 2, ± 5, ± 10% | 100 | 48 | 1.20 | 2.00 | 280 | 288 | 45 | - | - |

| 220 | ± 2, ± 5, ± 10% | 100 | 47 | 1.10 | 2.00 | 280 | 315 | 41 | - | - |

| 250 | ± 2, ± 5, ± 10% | 100 | 45 | 1.05 | 3.00 | 240 | - | - | - | - |

| 270 | ± 2, ± 5, ± 10% | 100 | 46 | 1.05 | 2.25 | 260 | - | - | - | - |

| 300 | ± 2, ± 5, ± 10% | 100 | 47 | 0.99 | 2.80 | 220 | - | - | - | - |

| 330 | ± 2, ± 5, ± 10% | 100 | 46 | 0.93 | 3.60 | 180 | - | - | - | - |

| 360 | ± 2, ± 5, ± 10% | 100 | 47 | 0.93 | 4.00 | 170 | - | - | - | - |

| 390 | ± 2, ± 5, ± 10% | 100 | 47 | 0.88 | 4.00 | 170 | - | - | - | - |

WL05(H) Wire Wound Chip Inductors / High Q Type

| Inductance (nH) | Tolerance | L Freq. (MHz) | Quality Factor min. | SRF (GHz) min. | DCR (Ω) max. | IDC (mA) max. |

|---|---|---|---|---|---|---|

| 2.5 | ± 5, ± 10% | 250 | 80 @ 1500MHz | 6.00 | 0.020 | 1600 |

| 5.6 | ± 5, ± 10% | 250 | 98 @ 1500MHz | 6.00 | 0.035 | 1600 |

| 6.2 | ± 5, ± 10% | 250 | 88 @ 1000MHz | 4.75 | 0.035 | 1600 |

| 6.8 | ± 5, ± 10% | 250 | 80 @ 1000MHz | 4.40 | 0.035 | 1600 |

| 8.2 | ± 5, ± 10% | 250 | 75 @ 1000MHz | 3.00 | 0.075 | 1000 |

| 10 | ± 5, ± 10% | 250 | 80 @ 1000MHz | 3.00 | 0.060 | 1600 |

| 12 | ± 5, ± 10% | 250 | 80 @ 1000MHz | 3.00 | 0.045 | 1600 |

| 15 | ± 2, ± 5, ± 10% | 250 | 80 @ 1000MHz | 2.80 | 0.100 | 1200 |

| 16 | ± 2, ± 5, ± 10% | 250 | 72 @ 500MHz | 2.95 | 0.060 | 1500 |

| 18 | ± 2, ± 5, ± 10% | 250 | 75 @ 500MHz | 2.55 | 0.060 | 1400 |

| 20 | ± 2, ± 5, ± 10% | 250 | 70 @ 500MHz | 2.05 | 0.055 | 1400 |

| 22 | ± 2, ± 5, ± 10% | 250 | 80 @ 500MHz | 2.00 | 0.100 | 1200 |

| 27 | ± 2, ± 5, ± 10% | 250 | 75 @ 500MHz | 2.00 | 0.070 | 1300 |

| 30 | ± 2, ± 5, ± 10% | 250 | 65 @ 500MHz | 1.95 | 0.095 | 1200 |

| 39 | ± 2, ± 5, ± 10% | 250 | 65 @ 500MHz | 1.60 | 0.110 | 1100 |

| 48 | ± 2, ± 5, ± 10% | 200 | 65 @ 500MHz | 1.40 | 0.095 | 1200 |

| 51 | ± 2, ± 5, ± 10% | 200 | 65 @ 500MHz | 1.40 | 0.120 | 1000 |

WL08(H) Wire Wound Chip Inductors / High Q Type

| Inductance (nH) | Tolerance | L Freq. (MHz) | Quality Factor min. | SRF (GHz) min. | DCR (Ω) max. | IDC (mA) max. |

|---|---|---|---|---|---|---|

| 3.0 | ± 5, ± 10% | 50 | 70 @ 1500MHz | 6.00 | 0.04 | 1600 |

| 3.9 | ± 5, ± 10% | 50 | 75 @ 1500MHz | 6.00 | 0.05 | 1600 |

| 4.1 | ± 5, ± 10% | 50 | 75 @ 1500MHz | 6.00 | 0.05 | 1600 |

| 7.8 | ± 5, ± 10% | 50 | 75 @ 500MHz | 3.80 | 0.05 | 1600 |

| 10 | ± 2, ± 5, ± 10% | 50 | 60 @ 500MHz | 3.60 | 0.06 | 1600 |

| 12 | ± 2, ± 5, ± 10% | 50 | 70 @ 500MHz | 2.80 | 0.06 | 1500 |

| 18 | ± 2, ± 5, ± 10% | 50 | 62 @ 350MHz | 2.70 | 0.07 | 1400 |

| 22 | ± 2, ± 5, ± 10% | 50 | 62 @ 350MHz | 2.05 | 0.07 | 1400 |

| 33 | ± 2, ± 5, ± 10% | 50 | 75 @ 350MHz | 1.70 | 0.09 | 1300 |

| 39 | ± 2, ± 5, ± 10% | 50 | 75 @ 350MHz | 1.30 | 0.09 | 1300 |

| 47 | ± 2, ± 5, ± 10% | 50 | 75 @ 350MHz | 1.45 | 0.12 | 1200 |

| 56 | ± 2, ± 5, ± 10% | 50 | 75 @ 350MHz | 1.23 | 0.12 | 1200 |

| 68 | ± 2, ± 5, ± 10% | 50 | 80 @ 350MHz | 1.15 | 0.13 | 1100 |

| 82 | ± 2, ± 5, ± 10% | 50 | 80 @ 350MHz | 1.06 | 0.16 | 1100 |

| 100 | ± 2, ± 5, ± 10% | 50 | 50 @ 350MHz | 0.82 | 0.16 | 1000 |

| 120 | ± 2, ± 5, ± 10% | 100 | 50 @ 100MHz | 0.82 | 0.16 | 1000 |

☑ Parts (3.0nH, 7.8nH) are wound on a low profile bobbin. (Max 2.41 x 2.01 x 1.09)

Electrical Performance Test

| Item | Requirement | Test Method |

|---|---|---|

| Inductance | Refer to standard electrical characteristic spec. | HP4286/E4982A |

| Q | HP4286/E4982A | |

| SRF | HP4287/E4982A | |

| DC Resistance RDC | Micro-Ohm meter (Gom-801G)/E4982A | |

| Rated Current IDC | Applied the current to coils, the temperature of coil increases ΔT15°C (Ta = 25°C). | |

| Over Load | Inductors shall have no evidence of electrical and mechanical damage | Applied 2 times of rated allowed DC current to inductor for a period of 5 minutes |

| Withstanding Voltage | Inductors shall be no evidence of electrical and mechanical damage. | AC voltage of 500 VAC applied between inductors terminal and case for 1 min. |

| Insulation Resistance | 1000M ohm min. | 100 VDC applied between inductor terminal and case |

Mechanical Performance Test

| Item | Requirement | Test Method |

|---|---|---|

| Vibration | Appearance: No damage L change: within ± 5% Q change: within ± 10% | Test device shall be soldered on the substrate Oscillation Frequency: 10 to 55 to 10Hz for 1 min. Amplitude: 1.5 mm Time: 2 hrs for each axis (X, Y & Z), total 6 hrs |

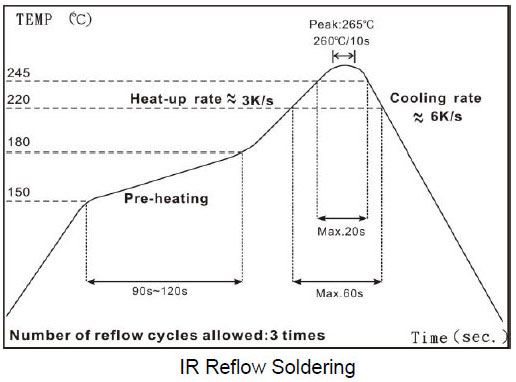

| Resistance to Soldering Heat | Solder Temperature: 260± 5°C Immersion Time: 10± 2 seconds | |

| Component Adhesion (Push Test) | 1 lbs. For 0402 2 lbs. For 0603 3 lbs. For the rest | The device should be soldered (260± 5°C for 10 seconds) to a tinned copper subs rate. A dynamiter force gauge should be applied to the side of the component. The device must with stand a minimum force of 2 or 4 pounds without a failure of adhesion on termination |

| Drop | No damage | Dropping chip by each side and each corner. Drop 10 times in total Drop height: 100 cm Drop weight: 125 g |

| Solderability | 90% covered with solder | Inductor shall be dipped in a melted solder bath at 245± 5°C for 3 seconds |

| Resistance to Solvent | No damage on appearance and marking | MIL-STD-202, Method 215 |

Climatic Test

| Item | Requirement | Item | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Temperature Characteristic | Appearance: No damage L change: within ± 10% Q change: within ± 20% | -40°C ~ +125°C | ||||||||||||||

| Humidity | Temperature: 40± 2°C Relative Humidity: 90 ~ 95% Time: 96± 2 hrs Measured after exposure in the room condition for 2 hrs | |||||||||||||||

| Low Temperature Storage | Temperature: -40± 2°C Time: 96± 2 hrs Inductors are tested after 1 hour at room temperature | |||||||||||||||

| Thermal Shock | One cycle:

Total: 5 cycles | |||||||||||||||

| High Temperature Storage | Temperature: 125± 2°C Time: 96± 2 hrs Measured after exposure in the room condition for 1hour | |||||||||||||||

| High Temperature Load Life | There should be no evidence of short of open circuit. | Temperature: 85± 2°C Time: 1000± 12 hrs Load: Allowed DC current | ||||||||||||||

| Damp Heat with Load | Temperature: 40± 2°C Relative Humidity: 90 ~ 95% Time: 1000± 12 hrs Load: Allowed DC current |

☑ Storage Temperature: 15 ~ 28°C; Humidity < 80%RH

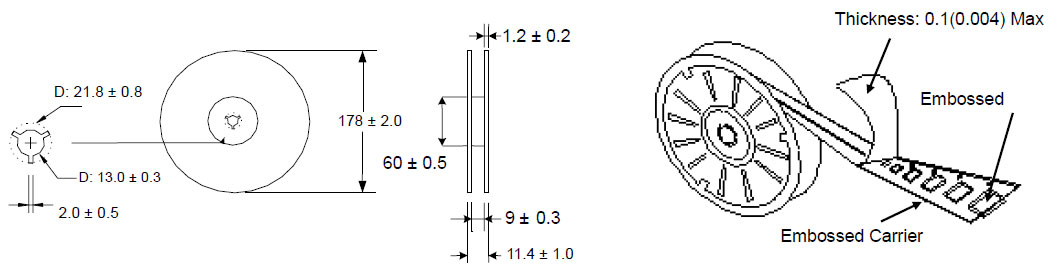

Reel Dimensions & Packaging Quantity (Unit : mm)

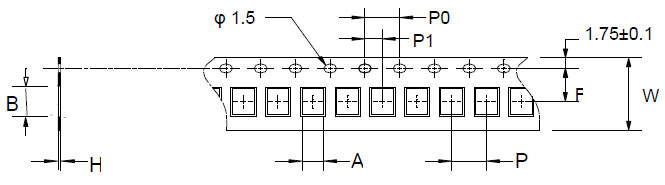

Paper Tape specification and Packaging Quantity (Unit : mm)

| Type | A | B | H | F | P | P0 | P1 | W | Reel (EA) |

|---|---|---|---|---|---|---|---|---|---|

| WL02 | 0.81 | 1.23 | 0.73 | 3.50 | 2.00 | 4.00 | 2.00 | 8.00 | 4,000 |

| WL03 | 1.35 | 1.95 | 0.95 | 3.50 | 4.00 | 4.00 | 2.00 | 8.00 | 4,000 |

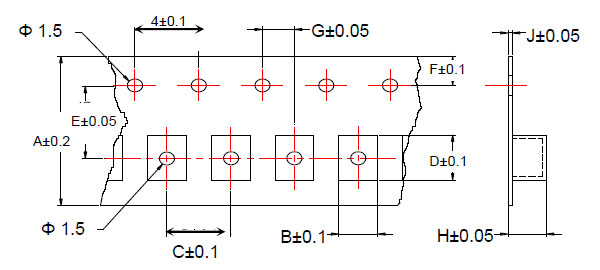

Embossed Plastic Tape specification and Packaging Quantity (Unit : mm)

| Type | A | B | C | D | E | F | G | H | J | Reel (EA) |

|---|---|---|---|---|---|---|---|---|---|---|

| WL05 | 8 | 1.85 | 4 | 2.30 | 3.5 | 1.75 | 2 | 1.45 | 0.23 | 2,000 |

| WL05 (H) | 8 | 1.85 | 4 | 2.30 | 3.5 | 1.75 | 2 | 1.45 | 0.23 | 2,000 |

| WL08 | 8 | 2.70 | 4 | 2.80 | 3.5 | 1.75 | 2 | 2.00 | 0.23 | 2,000 |

| WL08 (H) | 8 | 2.70 | 4 | 2.80 | 3.5 | 1.75 | 2 | 2.00 | 0.23 | 2,000 |

Thin film Precision resistor 0.01%, TC2ppm, wirebondale, Anti-Crossive, MELF. Current sensing, Metal...

Read More

Ceramic high frequency chip inductors, small size to 01005. Thin film, multilayer, wirewound , ferrite...

Read More

Multilayer Ceramic capacitor offers high Voltage, high frequency, low noise, High Q, Low TCR. NPO, X7R,...

Read More